Quickly-separated disconnecting switch

An isolating switch, fast technology, applied in the field of quick separation isolating switch, can solve the problems of reducing the reliability and service life of the high-voltage switchgear, failing to realize the fast opening function, and the contacts do not have fast separation, etc., to improve the cut-off bus conversion Current and small capacitive current capabilities, reduced arcing time and arc restrike times, simple and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] first preferred embodiment

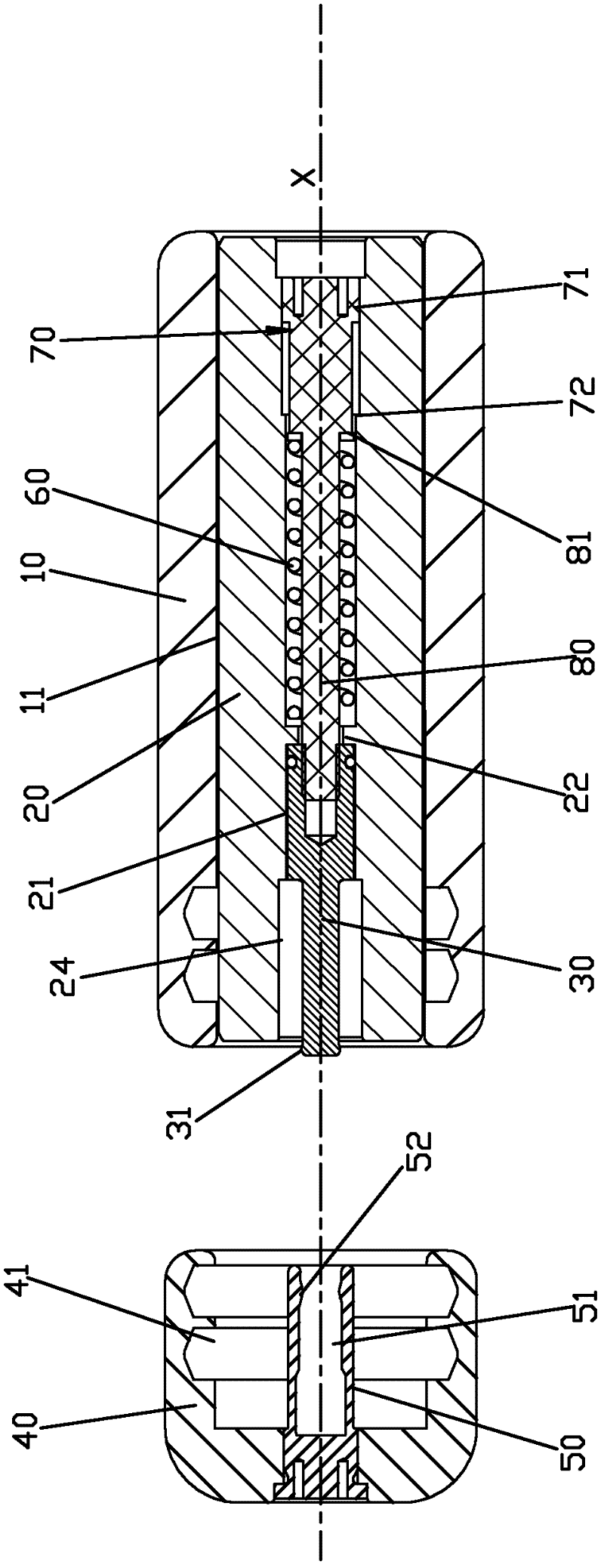

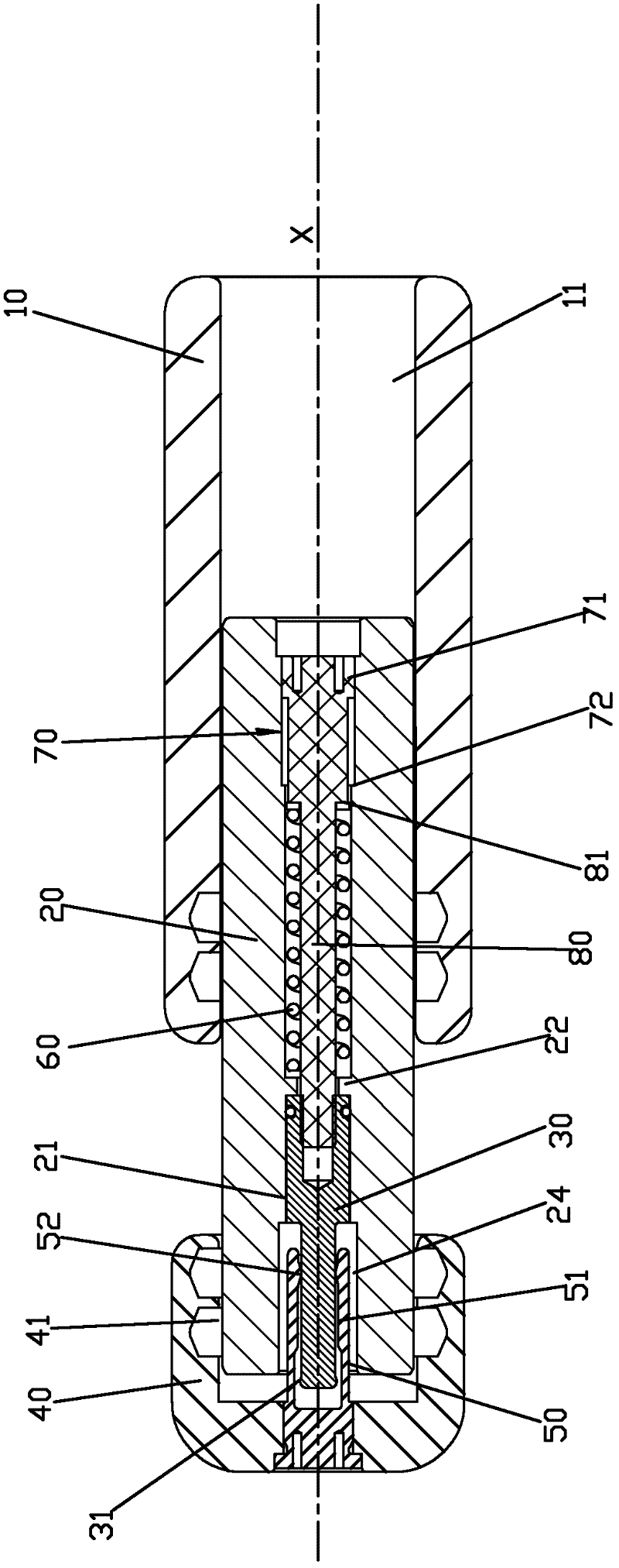

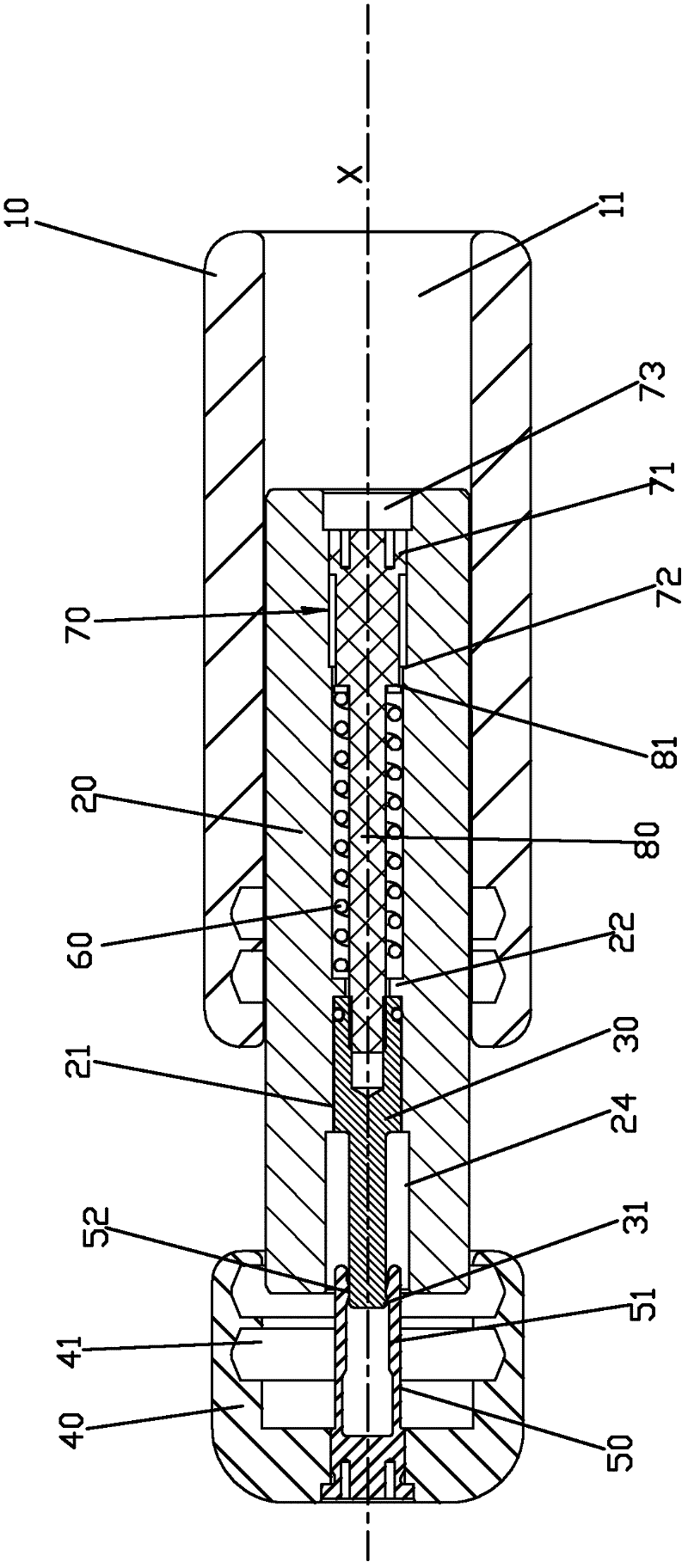

[0046] Please check Figure 1 to Figure 4, quick separation isolating switch, which includes an outer seat 10, a moving contact 20, a moving arc contact 30, a static contact 40, a static arc contact 50, an elastic body 60, a limit mechanism 70 and a continuous Rod 80.

[0047] The outer seat 10 is provided with a first sliding hole 11 along the line X. In this embodiment, the first sliding hole 11 is cylindrical, and the line X is the axis of the first sliding hole 11 .

[0048] The moving contact 20 is slidably arranged in the first sliding hole 11 so that the moving contact 20 can slide along the first sliding hole 11 under the action of the operating mechanism. In this embodiment, the movable contact 20 is a rotating body. The movable contact 20 is in conductive contact with the outer seat 10 . In this embodiment, in order to ensure the electrical conductivity, a contact guiding spring is provided between the outer revolving wall of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com