Double-capacity power transformer

A power transformer and capacity technology, applied in the field of transformers, can solve problems such as power grid outage, transformer outage, loss, etc., and achieve the effects of controlling magnetic flux leakage path, reducing temperature rise, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

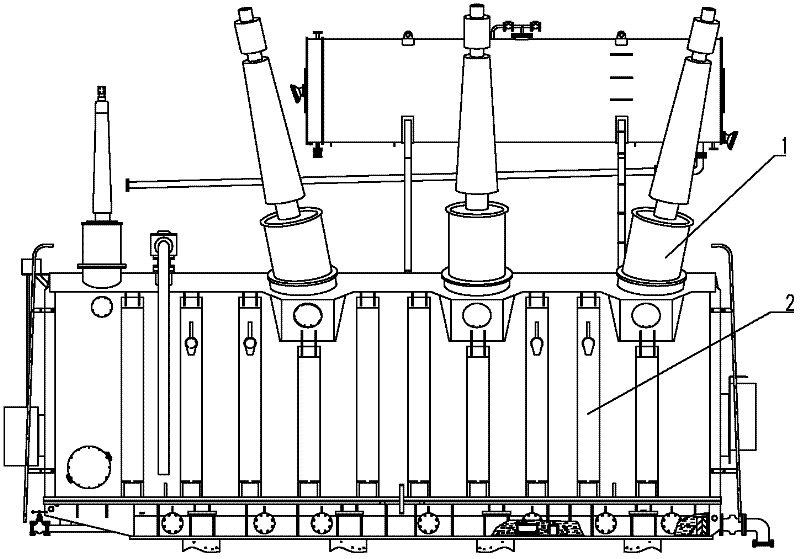

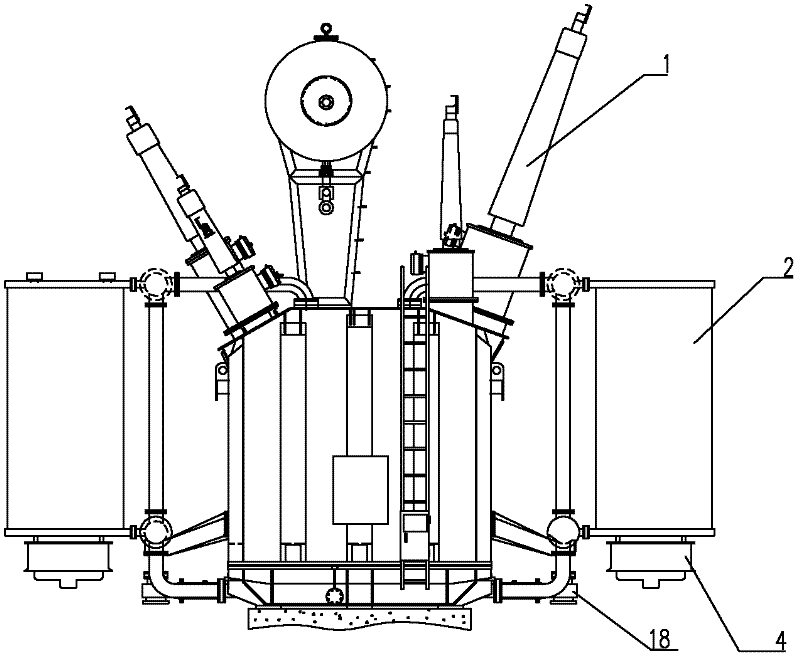

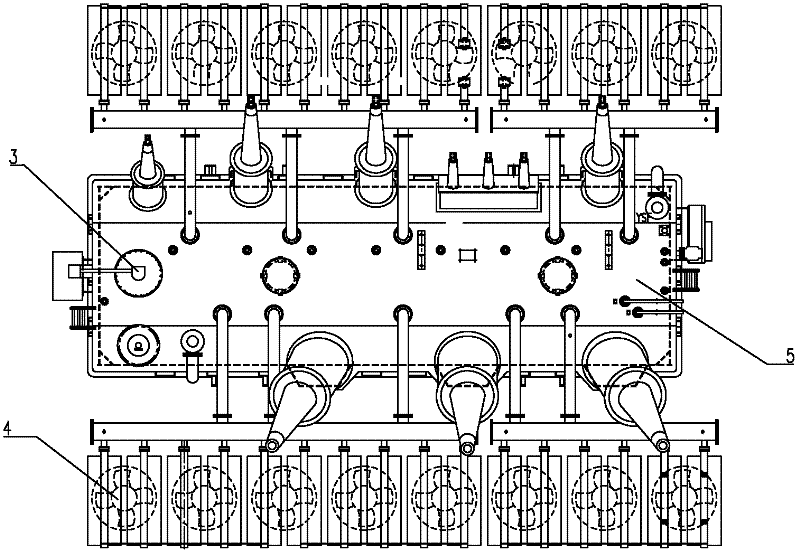

[0020] A double-capacity power transformer, as shown in the figure, includes an oil tank 5, an iron core 7, a winding, a fin radiator 2 and a cooling device installed outside the oil tank, each winding end is provided with a clamp 8, the inner wall of the oil tank 5 and the clamp Magnetic shields 6, 9 are provided on the piece 8, and the thickness of the magnetic shields 6, 9 is 10 mm. The windings include a low-voltage winding 14, a medium-voltage winding 12, a high-voltage winding 11, and a voltage-regulating winding 17 on one side of the high-voltage winding, which are sequentially set on the iron core 7. The high-voltage winding 11 and the medium-voltage winding 12 adopt an inner screen continuous structure The low-voltage winding 14 adopts a continuous structure, the voltage-regulating winding 17 adopts a double-helix structure, the high-voltage winding 11 adopts semi-hard copper transposed wires, and the medium-voltage winding 12 and low-voltage winding 14 adopt semi-hard...

Embodiment 2

[0022] In this embodiment, the thickness of the magnetic shield is 25mm, and the winding current density is 2.2A / mm 2 , the width of the wire at the end of the winding is 8.5mm, the width of the high-voltage winding oil passage spacer is 45mm, the width of the axial oil passage is 6mm, and the width of the winding oil passage is 6mm.

Embodiment 3

[0024] In this embodiment, the thickness of the magnetic shield is 20mm, and the winding current density is 2A / mm 2 , the width of the wire at the end of the winding is 7.5mm, the width of the high-voltage winding oil passage spacer is 40mm, the axial oil passage width is 6mm, and the winding oil passage width is 5mm. Other features are the same as those in Embodiment 1 and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com