Heater for heating fuel oil by using heat of engine

A technology for engines and heaters, which is applied in the direction of engine components, combustion engines, machines/engines, etc., can solve the problems of complex structure of heating devices, inconvenient installation, etc., achieve obvious fuel saving effects, improve combustion efficiency, and increase output power Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

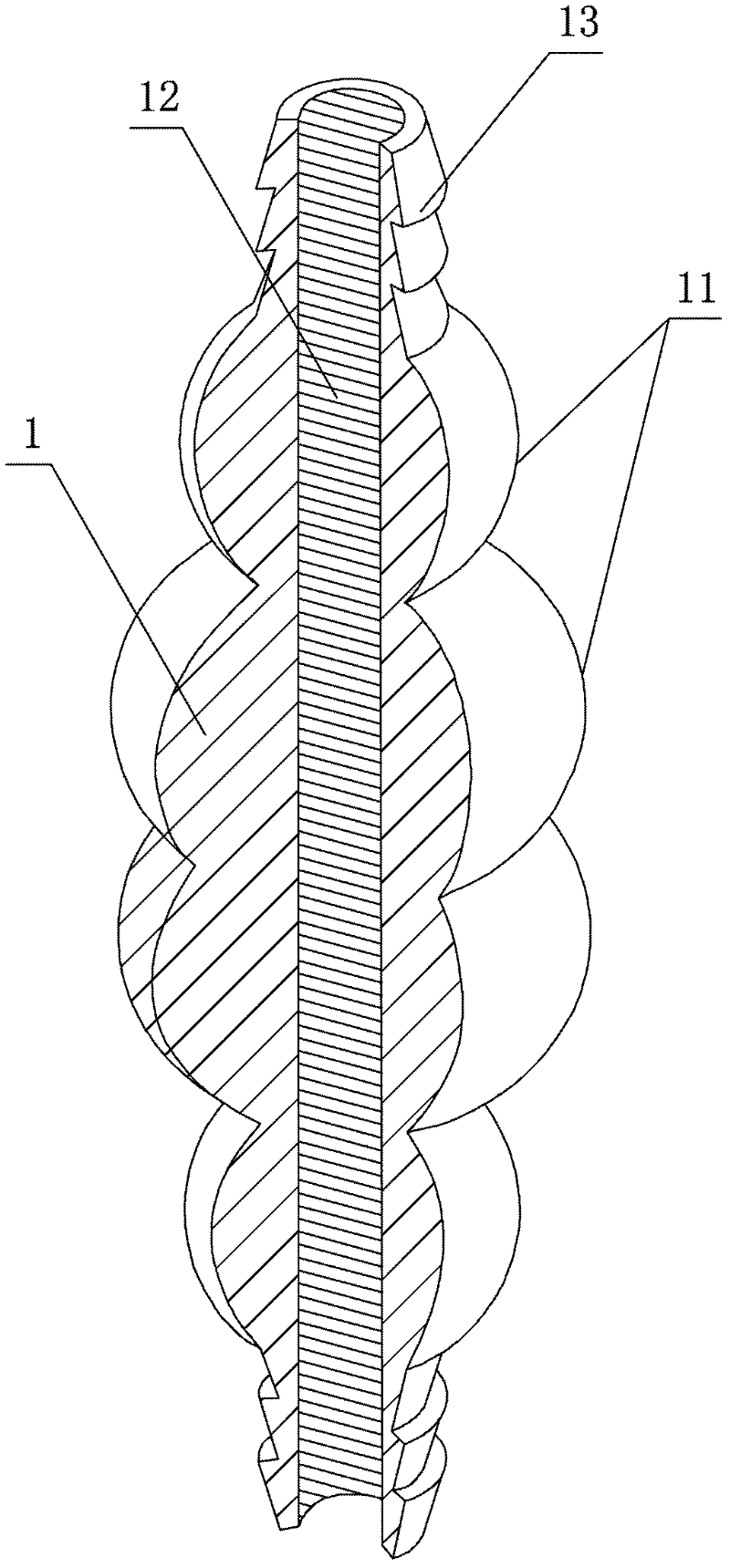

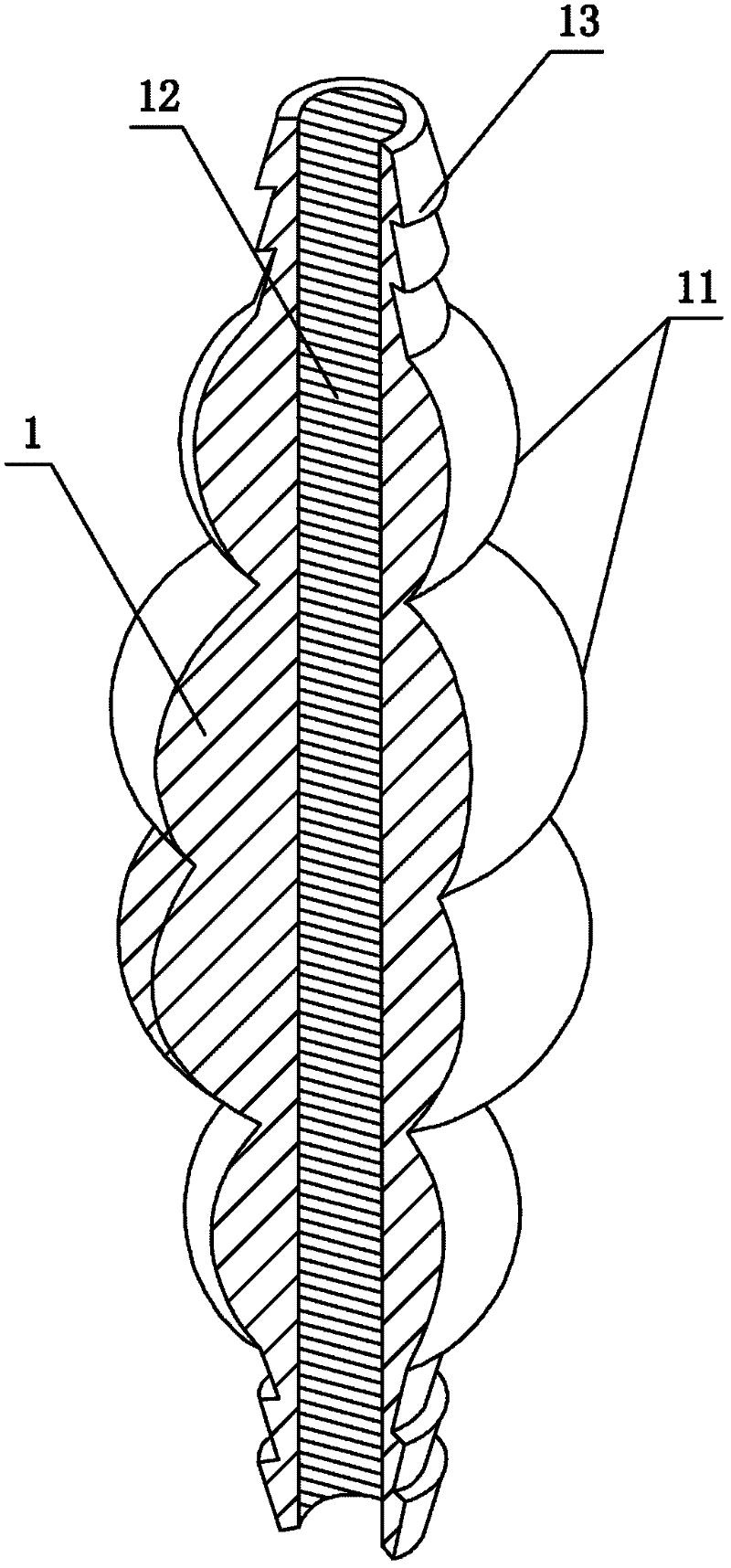

[0008] Such as figure 1 As shown, a heater that uses the heat of the engine to heat fuel oil includes a heat absorber 1 that is divided into several continuous sections that are raised parts 11, and the heat absorber 1 is provided with a fuel oil that passes through each raised section 11. The through hole 12 and the heat absorber 1 are respectively provided with a fuel pipe interface 13 at both ends of the through hole 12 .

[0009] In the actual production of this heater, in order to quickly prototyping and reflect its ease of processing, the raised part 11 is set into a spherical shape, so that it can be used as a heat absorbing body and a heating body for heating fuel oil at the same time, with circumferential consistency . The heater also sets the inner wall of the fuel through hole 12 into a thread shape, so that when the fuel flows through the heater, it flows in a vortex shape, which not only expands the heating area of the fuel, but also increases the distance of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com