Concrete pouring construction method for steel plate embedded part

A construction method and concrete technology, applied in construction, building structure, construction material processing, etc., can solve problems affecting project quality, high labor costs, displacement, etc., to achieve good project quality, convenient construction, and ensure molding quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

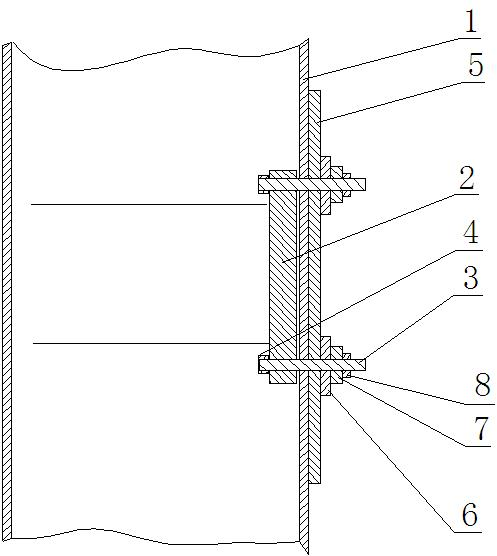

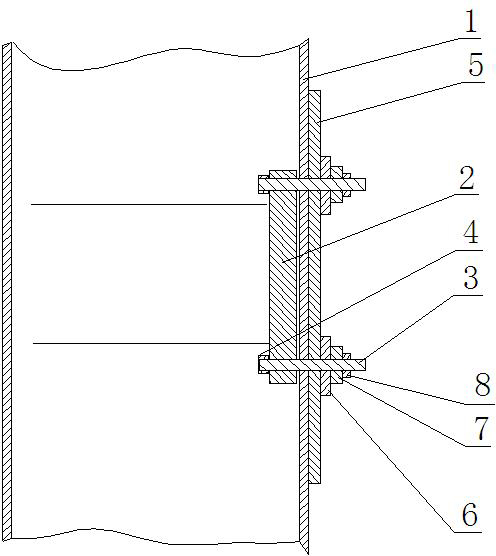

[0010] Such as figure 1 As shown, holes are drilled on the formwork 1 and the embedded steel plate 2 respectively, the bolts 3 are inserted into the holes of the formwork 1 and the embedded steel plate 2, the nuts 4 are arranged inside the formwork 1, and the nuts 4 are connected to the bolts 3 , the end of the bolt 3 on the inner side of the template 1 does not exceed the plane of the nut 4 .

[0011] A scaffolding tube 5 is also arranged outside the formwork 1, and a fixed fastener 6 is arranged between the bolt 3 and the scaffolding tube 5. A pressing piece 7 is placed outside the bolt 3 outside the fixing fastener 6, and on the bolt 3 outside the pressing piece 7 Attach another nut 8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com