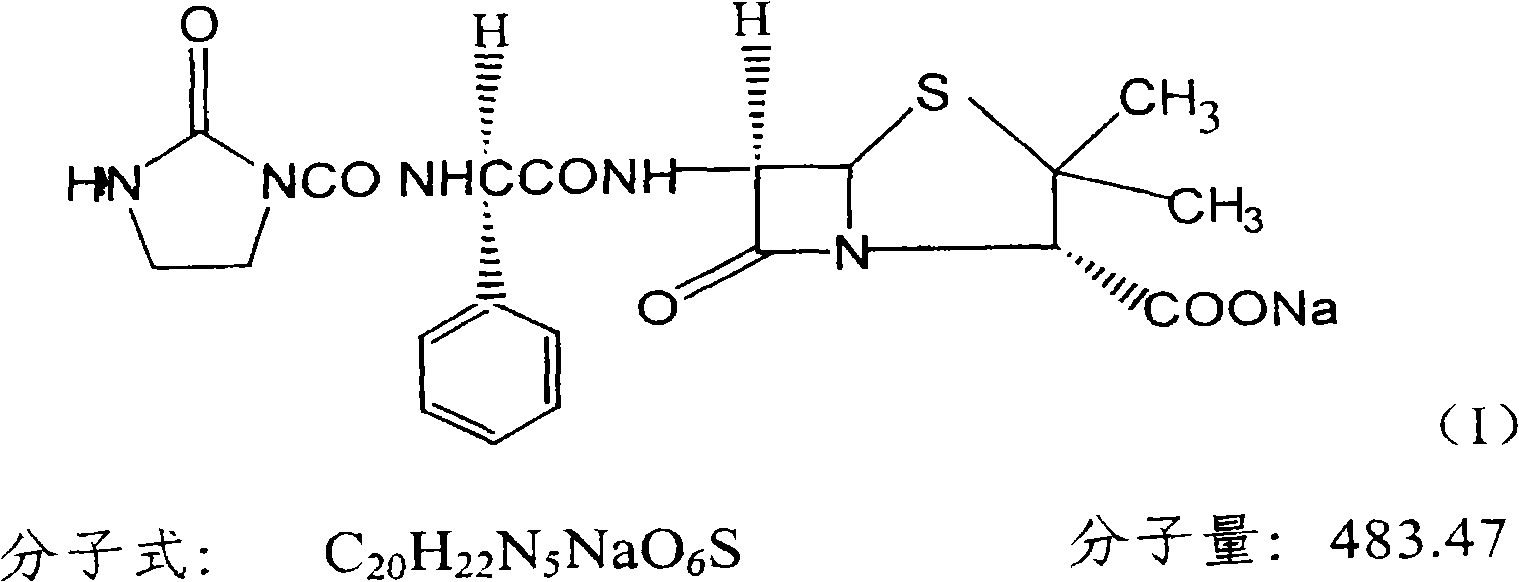

Method for preparing azlocillin sodium

A technology of azlocillin sodium and azlocillin acid, applied in the direction of organic chemistry, etc., can solve the problems of complex reaction, large usage, complicated process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] According to the preparation method of the azlocillin sodium of the present embodiment, it comprises the following steps successively:

[0017] (1) Prepare 5% sodium hydroxide solution for later use; weigh a certain amount of azlocillin acid and dissolve it in water to make a 40% aqueous solution of azlocillin sodium, place it in a low-temperature tank to cool, stir to cool down to 10°C, add Sodium salt-forming agent solution, stir until the solution is completely clear, filter, sterilize, and set aside;

[0018] (2) Place the above filtrate in a freeze-drying tray with a liquid layer thickness of 10-15mm, put it in the cold trap of a freeze dryer, pre-freeze-dry it at -35°C for 2 hours, and then vacuum freeze-dry it. The first stage:- 40℃~-5℃, the time is 5.5 hours; the second stage: -5℃~0℃, the time is 3.5 hours; the third stage: 0℃~30℃, the time is 1 hour, 30℃ continue to keep warm for about 4 hours, After the freeze-drying is finished, loose white azlocillin sodium...

Embodiment 2

[0020] According to the preparation method of the azlocillin sodium of the present embodiment, it comprises the following steps successively:

[0021] (1) Prepare 10% sodium isooctanoate and sodium carbonate mixed solution for subsequent use; take a certain amount of azlocillin acid and dissolve it in water to make a 60% aqueous solution of azlocillin sodium, place it in a low-temperature tank for cooling, and stir to cool down to 10°C, add sodium salt-forming agent solution, stir until the solution is completely clear, filter, sterilize, and set aside;

[0022] (2) Place the above filtrate in a freeze-drying tray with a liquid layer thickness of 10-15mm, put it in the cold trap of a freeze dryer, pre-freeze-dry it at -35°C for 2 hours, and then vacuum freeze-dry it. The first stage:- 40℃~-5℃, the time is 5.5 hours; the second stage: -5℃~0℃, the time is 3.5 hours; the third stage: 0℃~30℃, the time is 1 hour, 30℃ continue to keep warm for about 4 hours, After the freeze-drying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com