Ti-Nb oxide sintered body sputtering target, Ti-Nb oxide thin film, and method for producing the thin film

A technology for oxide thin films and sintered bodies, which can be used in the manufacture of optical record carriers, sputter coating, recording/reproducing by optical methods, etc., can solve the problem of insufficient disclosure of technical content, insufficient research, and no mention of and other problems, to achieve the effect of excellent transmittance, less decrease in reflectivity, and improved film formation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

[0064] As a raw material, prepare high-purity (4N) titanium oxide (TiO 2 ) And high purity (4N), niobium acid (Nb) with an average particle size of 3μm 2 O 5 ) The powder is blended with the composition ratio shown in the following table. Then, these powders with adjusted ingredients were mixed using a dry blender, and then calcined at 1000°C. After that, it was treated with a wet ball mill for about 20 hours, and finely pulverized to a particle size of 1 μm to prepare a slurry.

[0065] Then, the slurry was dried with a dryer, and then filled in a carbon mold and hot-pressed. The hot pressing conditions are: 1200℃, surface pressure 300kgf / cm 2 . The targets produced in this way all have a relative density of over 90%.

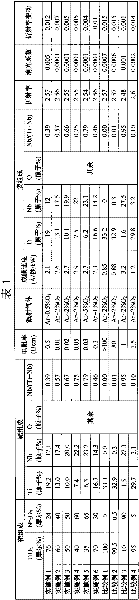

[0066] Through the above operations, a Ti-Nb-based oxide sintered body sputtering target having the composition shown in Table 1 can be obtained. As shown in Table 1, the resistivity of the target is 0.01 to 0.5 Ωcm. Perform XRD measurement on the sample taken ...

Embodiment 2

[0075] Regarding Example 2, the atomic ratio of Ti to Nb in both the target composition and the film composition is 0.57, which falls within the range of 0.39≦(Nb / (Ti+Nb))≦0.79 in the present invention. As a result, the resistivity is as low as 0.01Ωcm, and the film formation speed is as high as It is a sputtering target suitable for the purpose of the present application. In addition, the refractive index of the thin film is as high as 2.56, and the amount of refractive index variation is 0.007, which is stable, and the extinction coefficient is as low as 0.0001, which can form suitable interference films or protective films for optical recording media.

Embodiment 3

[0076] Regarding Example 3, the atomic ratio of Ti to Nb in the target composition is 0.67, and the atomic ratio of Ti to Nb in the film composition is 0.66, which falls within the range of 0.39≤(Nb / (Ti+Nb))≤0.79 in the present invention Inside. As a result, the resistivity is as low as 0.02Ωcm, and the film formation speed is as high as It is a sputtering target suitable for the purpose of the present application. In addition, the refractive index of the film is as high as 2.55, and the refractive index variation is 0.005, which is stable, and the extinction coefficient is as low as 0.0001, and can form suitable interference films or protective films for optical recording media.

[0077] Regarding Example 4, the atomic ratio of Ti to Nb in the target composition is 0.75, and the atomic ratio of Ti to Nb in the film composition is 0.75, which falls within the range of 0.39≤(Nb / (Ti+Nb))≤0.79 in the present invention Inside. As a result, the resistivity is as low as 0.05Ωcm, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com