Double-U-shaped coil

A coil and U-shaped technology, applied in the direction of transformer/inductor coil/winding/connection, etc., can solve the problems of tight main insulation distance, reduce coil reactance height, and high reactance height, so as to increase the main insulation distance and reduce reactance height , The effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

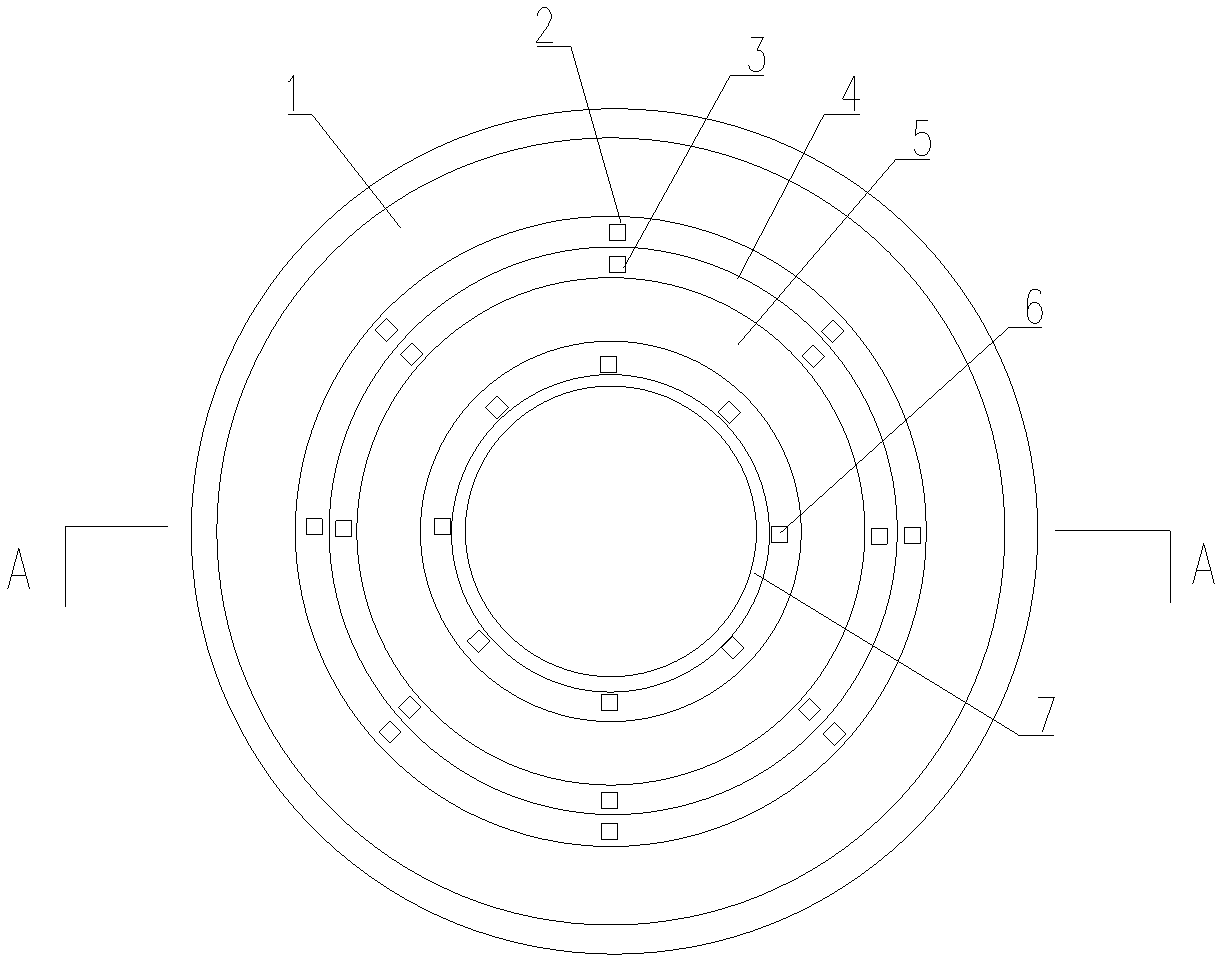

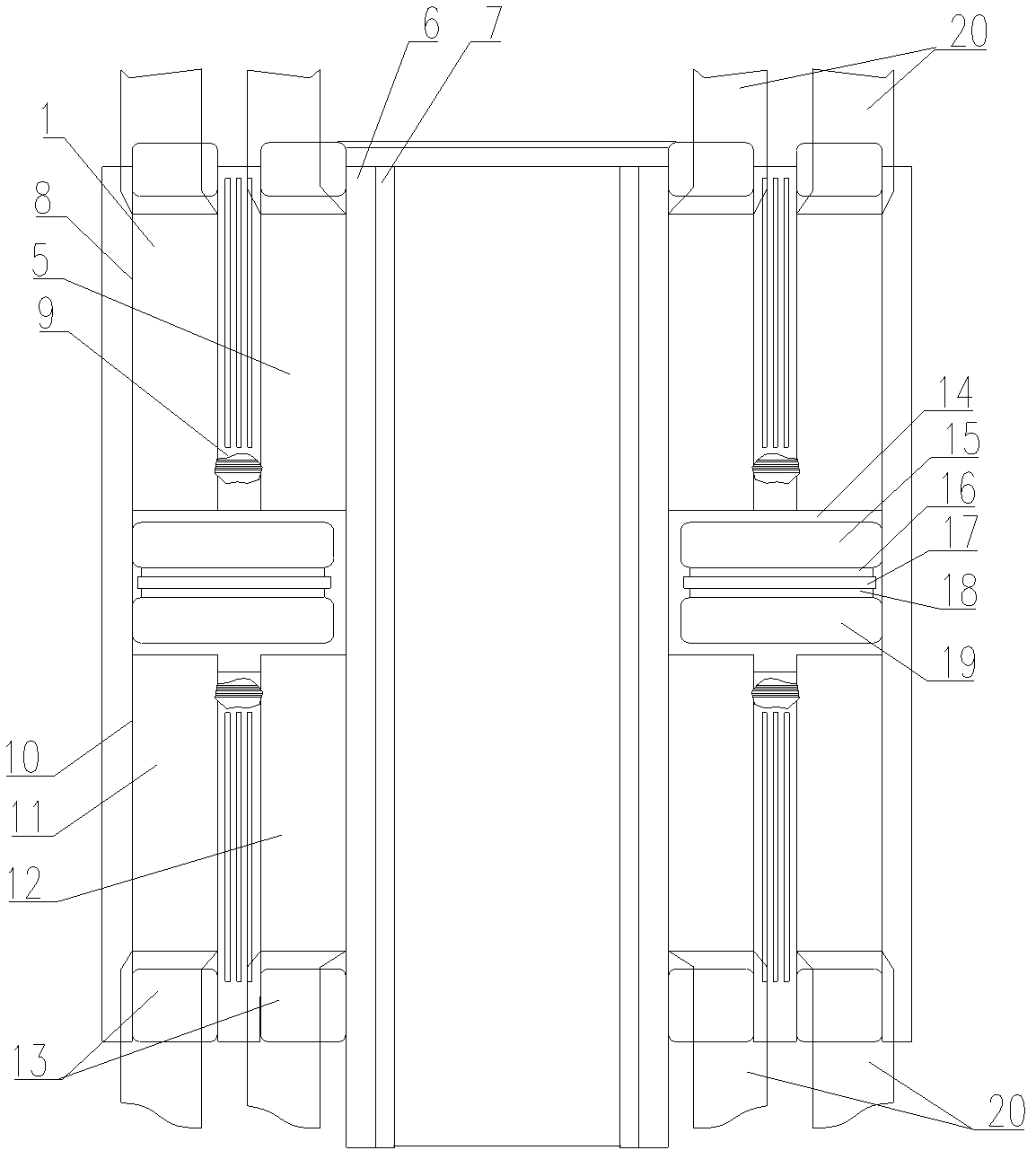

[0014] A double U-shaped coil, as shown in the figure, includes an upper coil 8 and a lower coil 10, the upper coil 8 is a U-shaped structure composed of an inner coil 5 and an outer coil 1, and the lower coil 10 is composed of an inner coil 12 The U-shaped structure formed with the outer layer coil 11, after the inner layer wires 5, 12 are wound, the upper layer is transposed, and the outer layer coils 1, 11 are continued to be wound, and the upper layer is provided with a wedge-shaped pad 9 at the upper layer transposition, There is a radial insulation mechanism between the inner coil and the outer coil. The radial insulation mechanism adopts a three-layer structure of stays 2, cardboard 4 and stays 3. The ends of the inner coil and the outer coil are provided with insulating ends. Circle 13. An axial insulation mechanism is provided between the upper coil 8 and the lower coil 10. The mechanism includes an insulating spacer 16, a paper ring 17 and an insulating spacer 18 arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com