Method for determining subway busbar aluminium alloy section tension

A technology of aluminum alloy profiles and measurement methods, applied in force/torque/power measuring instruments, measuring devices, instruments, etc., can solve problems such as cost reduction, achieve cost reduction, ensure factory pass rate, and overcome waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

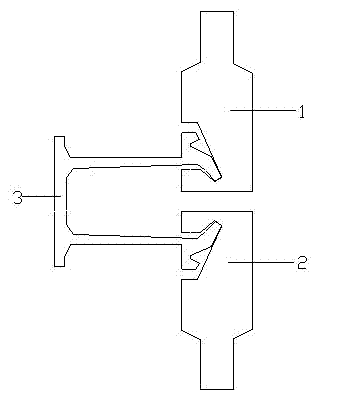

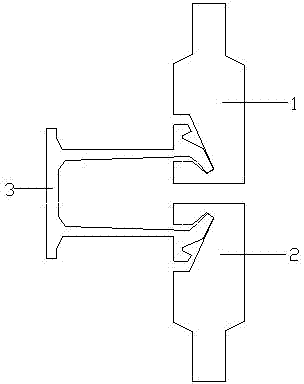

[0015] figure 1 It is a diagram of the use state of the clamp and the subway bus bar of the present invention. As shown in the figure, the method for measuring the tension force of the aluminum alloy profile of the subway bus bar of the present embodiment includes the following steps:

[0016] a. Loading force: load symmetrically on both sides of the dovetail groove of the metro bus bar to be tested, so that the two sides of the dovetail groove produce relative opening displacement; in this embodiment, the electronic tensile test machine is used for loading and force, and the upper fixture is set on the electronic tensile testing machine 1 and lower fixture 2, when in use, connect the upper and lower fixtures with the dovetail groove of the bus bar 3 of the test piece in the form of hooks, and tightly bite between the upper and lower fixtures and the bus bar of the subway. It will slip out to ensure the smooth progress of the measurement process and the accuracy of the measur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com