Industrialized production method for methyl p-tolyl sulfone

A technology of thiamphenyl toluene and p-thymphenyl toluene, which is applied in the field of industrial production of p-thymphenyl toluene, and can solve the problems of large equipment investment, heavy labor stress, and high labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

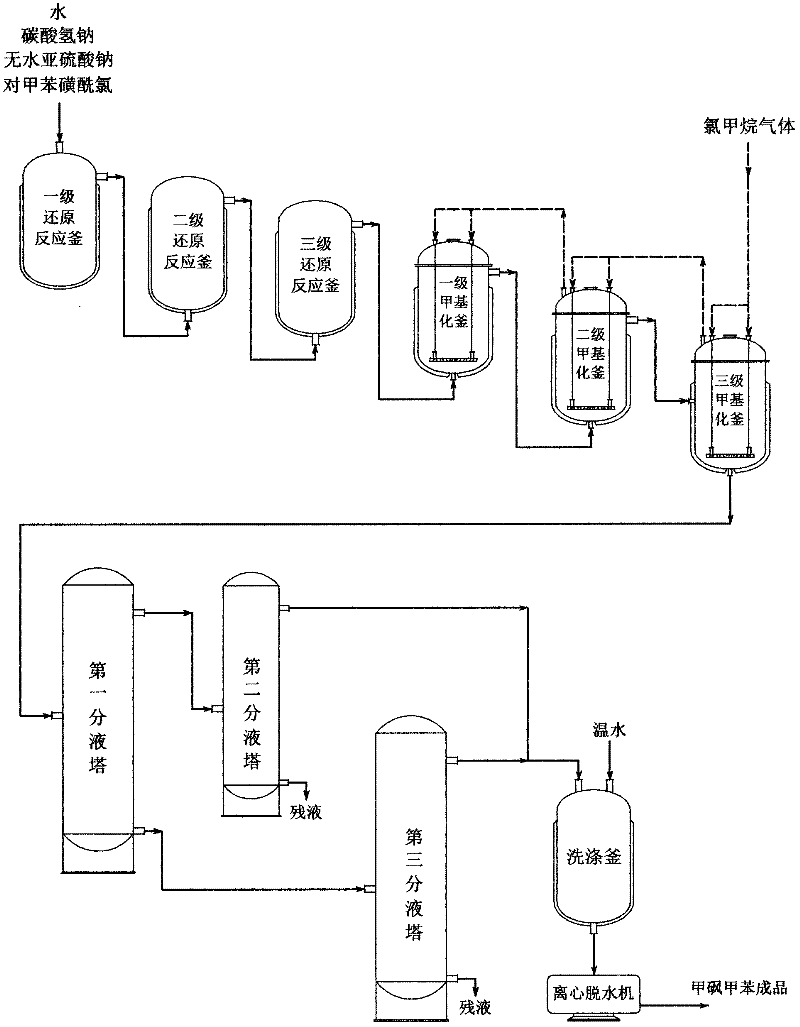

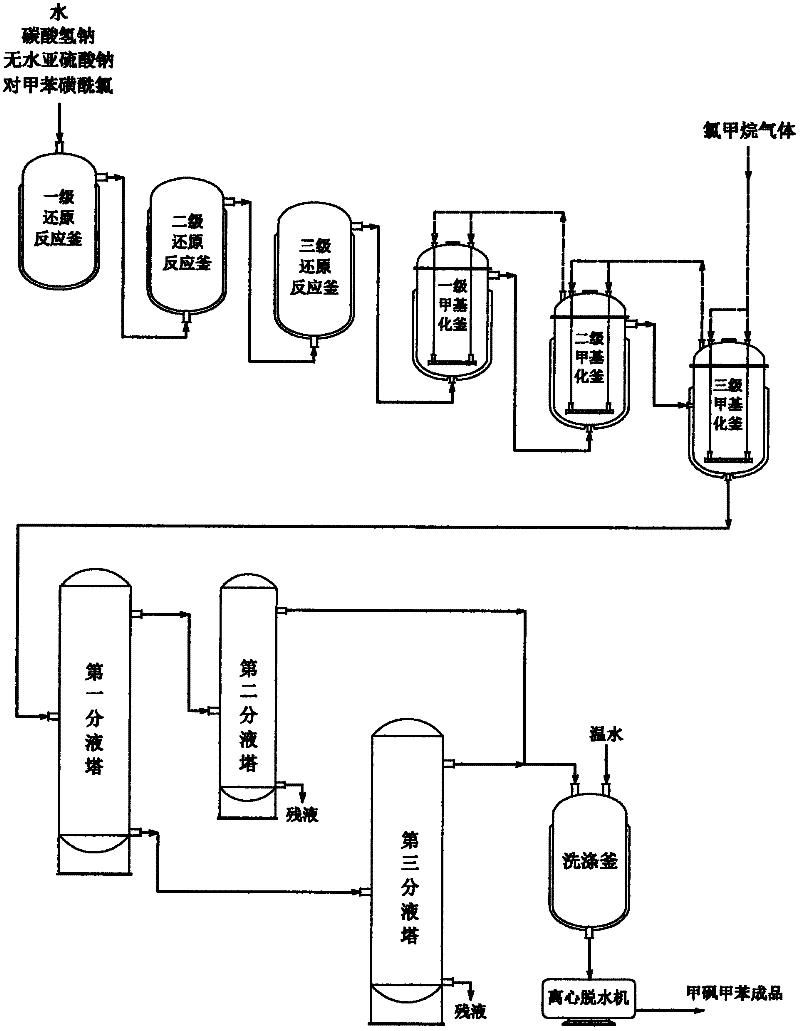

Image

Examples

Embodiment 1

[0031] Anhydrous sodium sulfite, sodium bicarbonate, p-toluenesulfonyl chloride and water are continuously put into the primary reduction reaction kettle according to the mass ratio of 0.72:1:1:3. The feed rate of p-toluenesulfonyl chloride is 490kg / h, the feed rate of anhydrous sodium sulfite is 352.8kg / h, the feed rate of sodium bicarbonate is 490kg / h, and the feed rate of water is 1470kg / h. The stirring is started, the temperature of the primary and secondary reduction reactors is maintained at 50-60°C, and the temperature of the third-stage reduction reactor is maintained at 70-80°C. The material enters the secondary reactor from the overflow port of the primary reactor, and then enters the third-stage heating reactor. Then enter the methylation multi-tank series system.

[0032] The material entering the stainless steel methylation kettle automatically flows from the liquid in the previous kettle to the next kettle through overflow in the methylation kettle, and graduall...

Embodiment 2

[0036]Anhydrous sodium sulfite, sodium bicarbonate, p-toluenesulfonyl chloride and water are continuously put into the primary reduction reaction kettle according to the mass ratio of 0.72:1:1:3. The feed rate of p-toluenesulfonyl chloride is 490kg / h, the feed rate of anhydrous sodium sulfite is 352.8kg / h, the feed rate of sodium bicarbonate is 490kg / h, and the feed rate of water is 1470kg / h. The stirring is started, the temperature of the primary and secondary reduction reactors is maintained at 50-60°C, and the temperature of the third-stage reduction reactor is maintained at 70-80°C. The material enters the secondary reactor from the overflow port of the primary reactor, and then enters the third-stage heating reactor. Then enter the methylation multi-tank series system.

[0037] The material entering the stainless steel methylation kettle automatically flows from the liquid in the previous kettle to the next kettle through overflow in the methylation kettle, and gradually...

Embodiment 3

[0041] Anhydrous sodium sulfite, sodium bicarbonate, p-toluenesulfonyl chloride and water are continuously put into the primary reduction reaction kettle according to the mass ratio of 0.72:1:1:3. The feed rate of p-toluenesulfonyl chloride is 490kg / h, the feed rate of anhydrous sodium sulfite is 3528kg / h, the feed rate of sodium bicarbonate is 490kg / h, and the feed rate of water is 1470kg / h. The stirring is started, the temperature of the primary and secondary reduction reactors is maintained at 50-60°C, and the temperature of the third-stage reduction reactor is maintained at 70-80°C. The material enters the secondary reactor from the overflow port of the primary reactor, and then enters the third-stage heating reactor. Then enter the methylation multi-tank series system.

[0042] The material entering the methylation tank automatically flows from the liquid in the previous tank to the next tank through overflow in the methylation tank, and gradually participates in the rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com