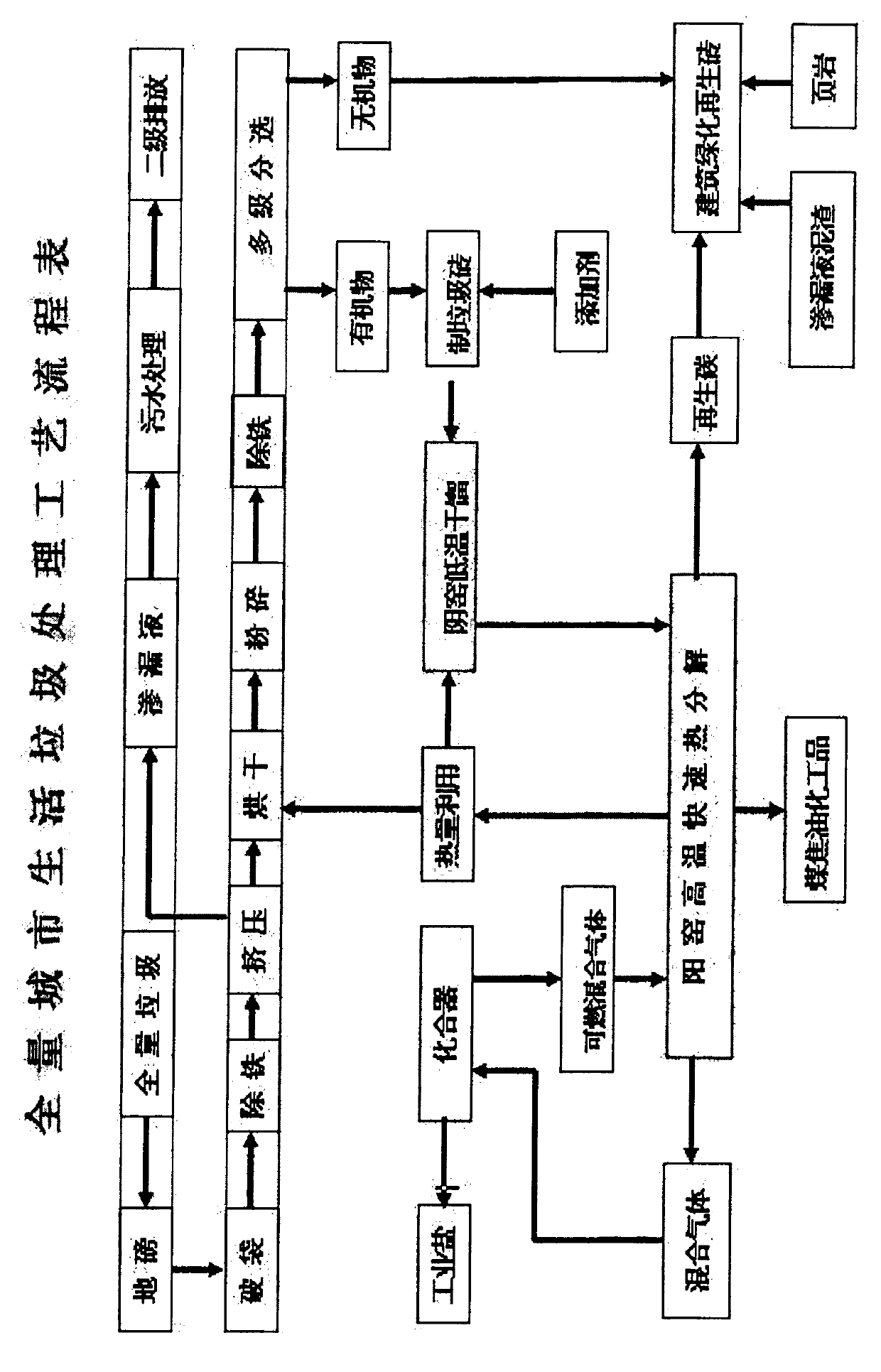

Low-temperature dry distillation and high-temperature quick thermal decomposition treatment process method for municipal domestic garbage

A high-temperature and rapid technology for municipal solid waste, which is applied in the field of low-temperature carbonization and high-temperature rapid thermal decomposition of municipal solid waste, can solve the problems of non-reduction of waste, waste of renewable resources, secondary pollution, etc., and achieve high value Utilize, realize full resource recovery, and achieve the effect of large profits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Embodiments of the invention:

[0016] 1. Squeeze the garbage, concentrate the leaching solution in the storage tank, and then meet the secondary discharge standard after treatment, and carbonize the sludge.

[0017] 2. The garbage is crushed, squeezed, dried, and subjected to primary and secondary crushing, and the metals are classified and recycled after magnetic separation.

[0018] 3. After the crushed garbage is selected by wind and screened, the organic matter and plastic are separated from the inorganic solid waste; the organic matter and plastic enter the kiln for dry distillation, and the inorganic matter enters the brick workshop.

[0019] 4. Dry distillation, dehydration, and deoxygenation of the dried garbage and shale bricks made of additives in the yin kiln; the temperature of the yang kiln is at 400-1000 ℃, and the garbage bricks are rapidly thermally decomposed and carbonized due to the action of additives ; The organic matter in the garbage is decompos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com