Branched conjugated diene-aromatic vinyl copolymer and method for producing same

A technology of aromatic vinyl and chain-like conjugated diene, which is applied in the field of branched-chain conjugated diene-aromatic vinyl copolymer and its manufacturing, and can solve problems such as narrow molecular weight distribution, increased viscosity, and increased energy consumption. problems, to achieve the effects of excellent balance, excellent productivity, low hysteresis loss and excellent wet skid resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0194] Two autoclaves are connected in series, the internal volume of the autoclave is 10L, the ratio (L / D) of the height (L) to the diameter (D) of the inside is 4, the bottom has an inlet, the top has an outlet, and a stirrer and Jacket for temperature regulation, the first autoclave was used as the polymerization reactor and the second autoclave was used as the coupling reactor.

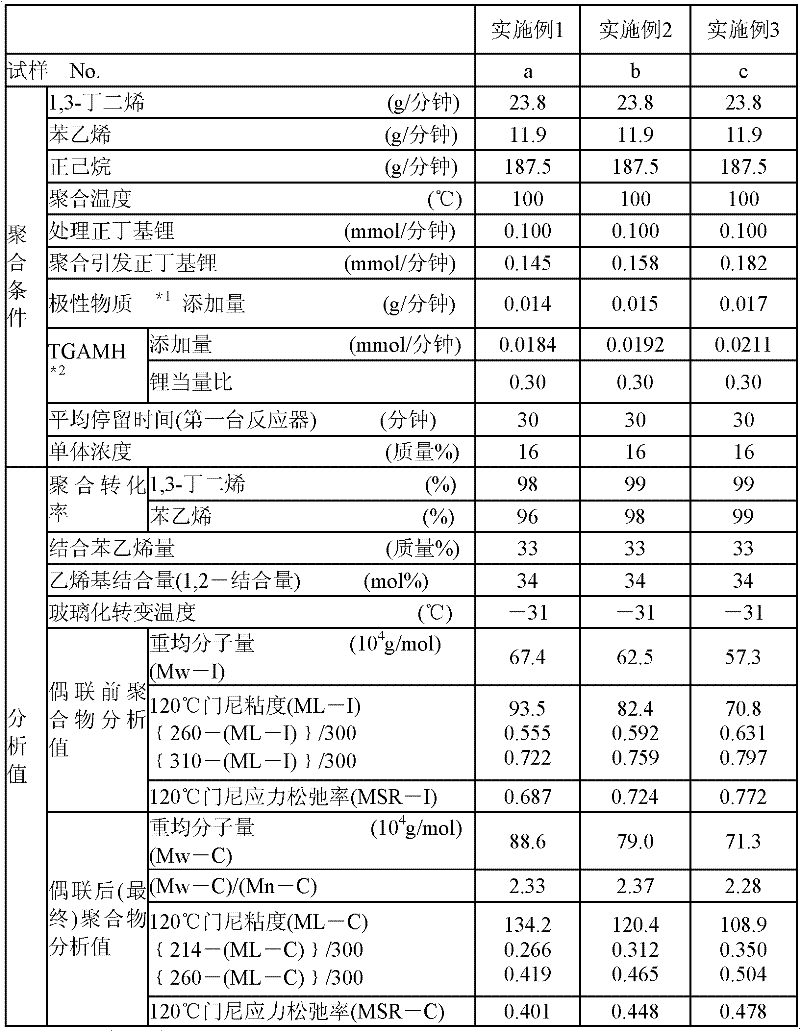

[0195] 23.8 g / min of 1,3-butadiene, 11.9 g / min of styrene, and 187.5 g / min of n-hexane from which impurities such as moisture were removed were mixed to prepare a mixed solution. With the obtained mixed solution, n-butyllithium for impurity inertization treatment (n-butyllithium treatment) was mixed at an addition rate of 0.100 mmol / min using a static mixer. The mixed solution was continuously supplied to the bottom of the first polymerization reactor, while 2,2-di(2-tetrahydrofuryl)propane as a polar substance was added at a rate of 0.014 g / min, and as a polymerization initiator The n-butyllithi...

Embodiment 2、3

[0202] Under the conditions shown in Table 1, n-butyllithium, 2,2-bis(2-tetrahydrofuryl)propane and tetraglycidyl-1,3-bisaminomethylcyclohexane were used as polymerization initiators. Other conditions were the same as in Example 1 to obtain oil-extended copolymers (sample b, c). The properties of the obtained copolymers are listed in Table 1.

Embodiment 4

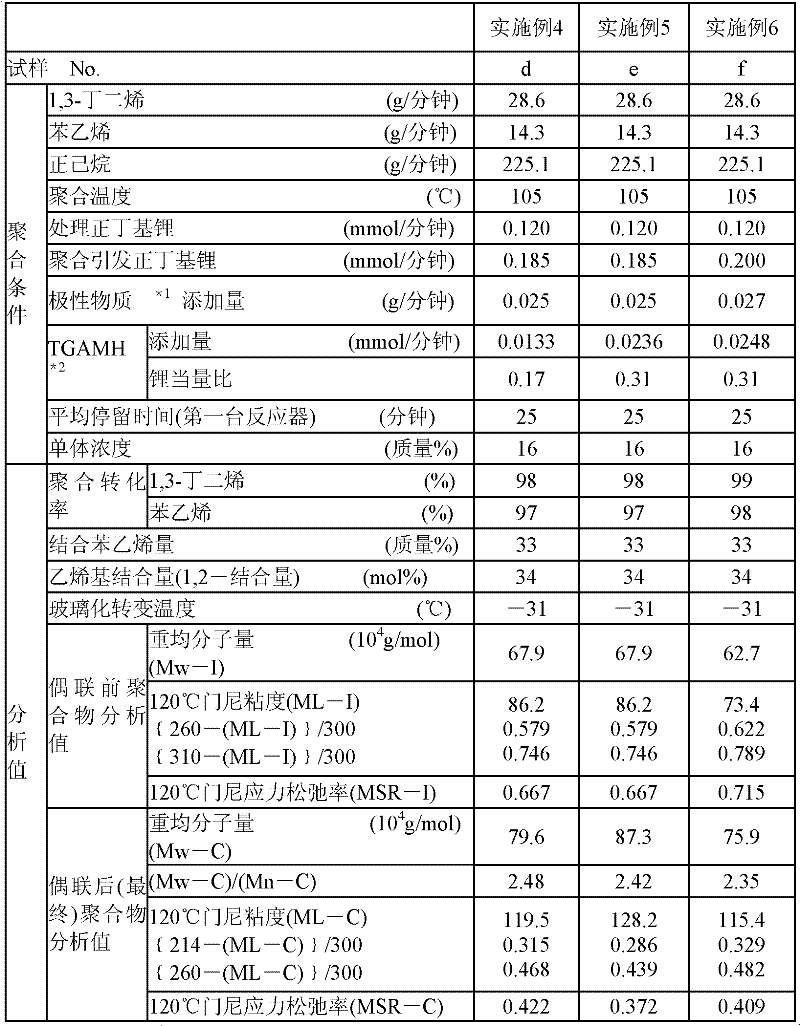

[0204] As shown in Table 2, in the method of embodiment 1, do not change the amount ratio of 1,3-butadiene and styrene, change the supply rate of monomer, make the average residence time be 25 minutes, the interior of reactor outlet The temperature was 105° C., and the supply amounts of other substances were also changed as shown in Table 1 to perform polymerization and coupling reactions. Thereafter, addition of oil and solvent removal were carried out in the same manner as in Example 1 to obtain an oil-extended copolymer (sample d). The properties of the obtained copolymers are listed in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com