Circuit board processing method

A processing method and circuit board technology, applied in printed circuit, printed circuit manufacturing, electrical components, etc., can solve the problems of increasing process difficulty, reducing yield rate, increasing cost, etc., to expand the area of wiring area, reduce wiring density, improve The effect of product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

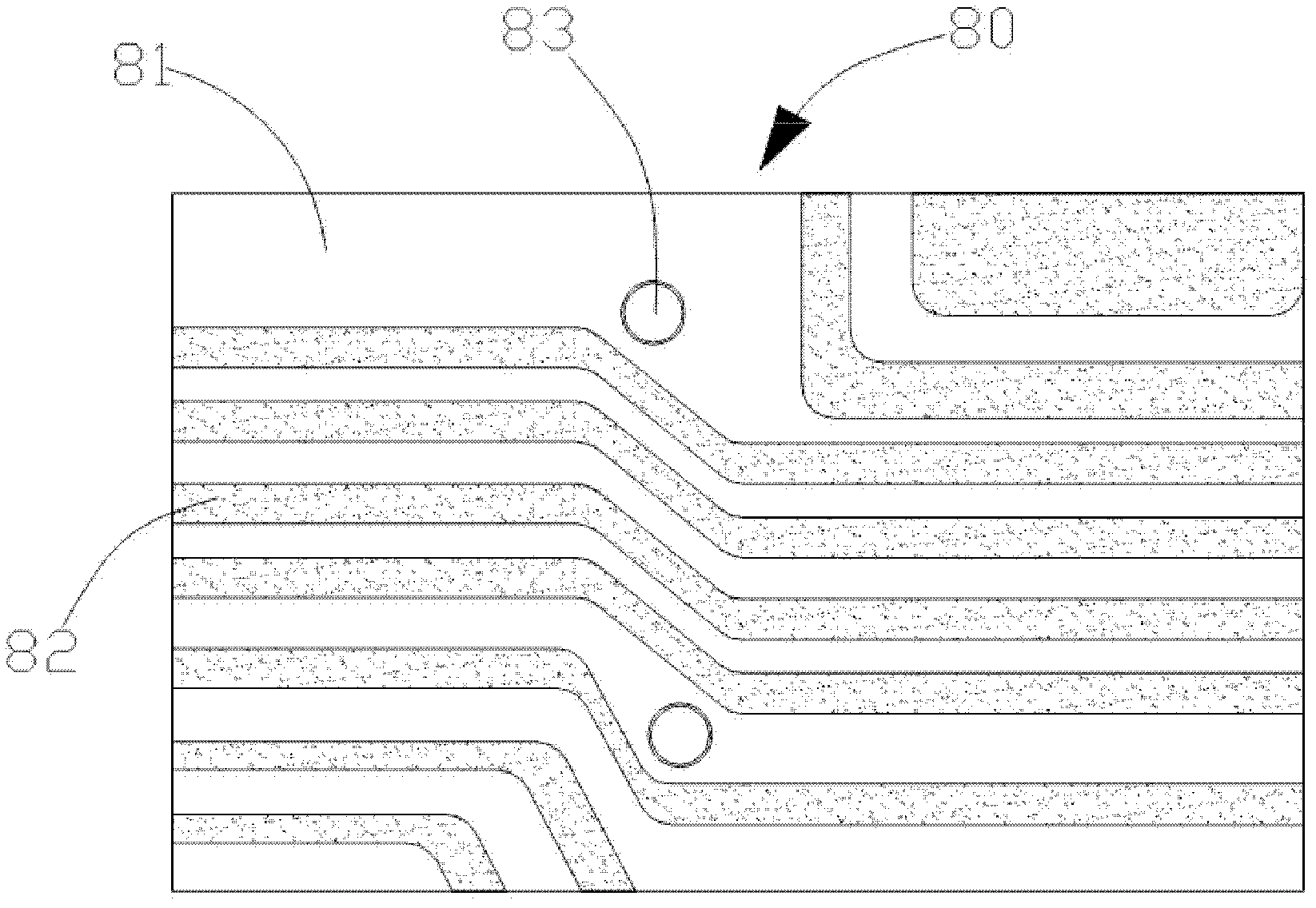

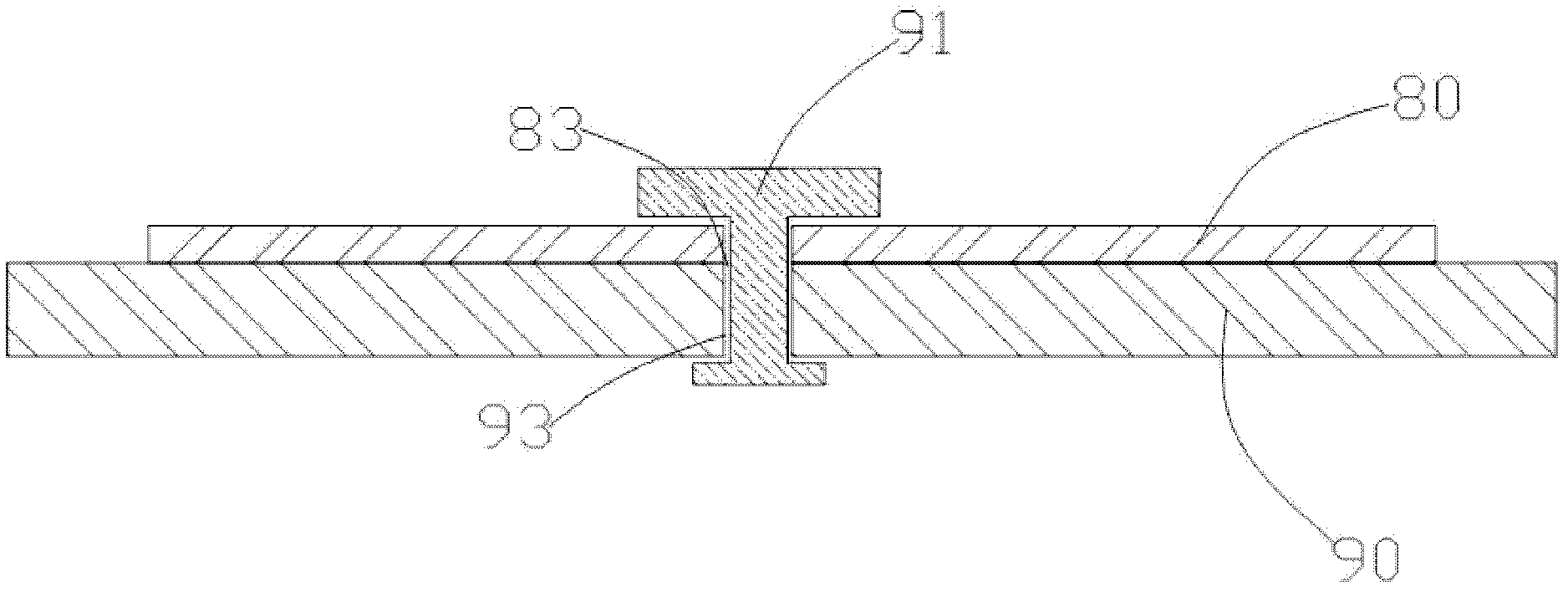

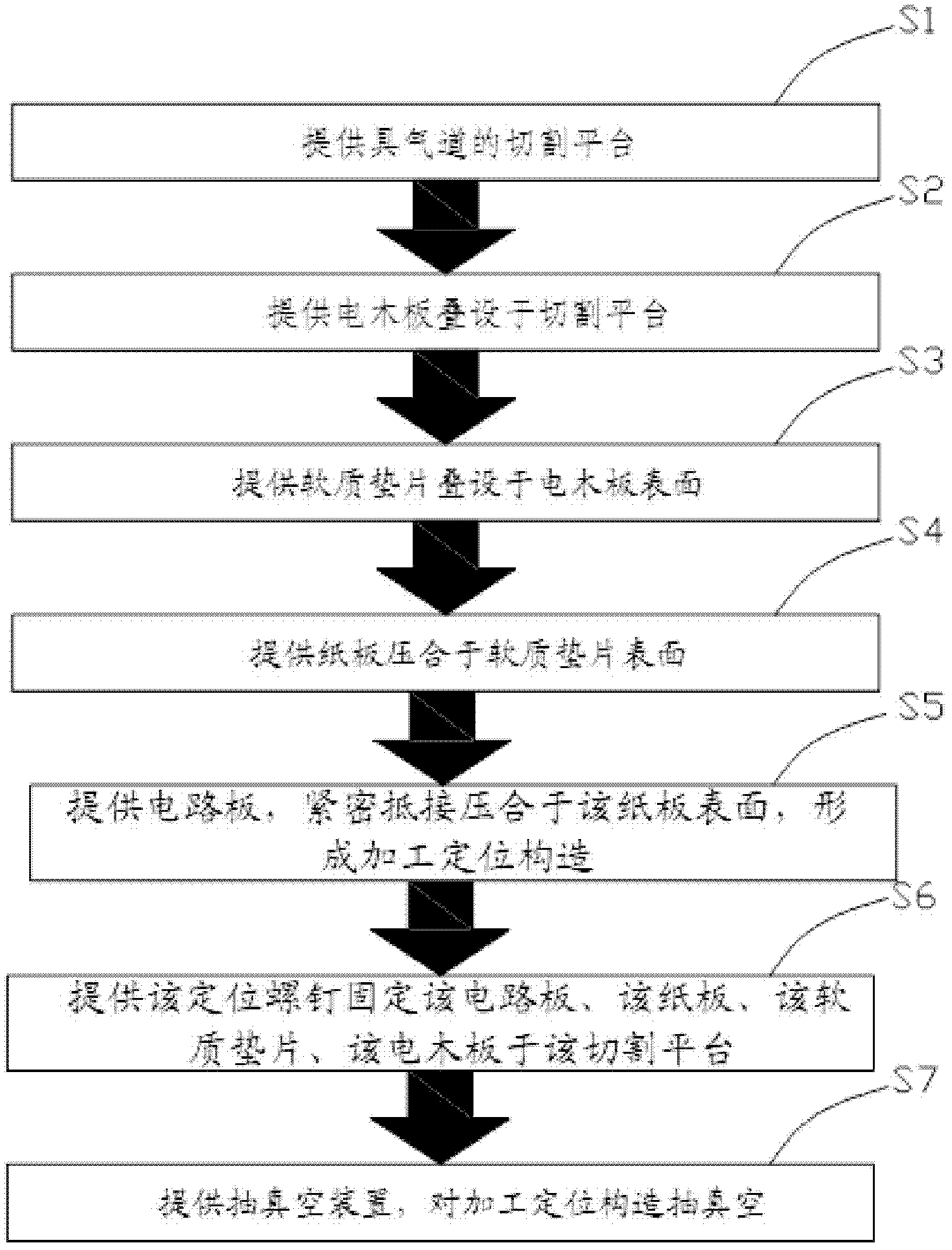

[0029] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0030] Circuit boards can be divided into single-sided, double-sided and multi-layer boards according to their wiring levels. A single-sided circuit board is a printed board that is provided with conductive patterns on only one surface. Generally, it is made of phenolic paper-based copper-clad foil layer, and epoxy paper-based or epoxy glass cloth copper-clad laminate is often used.

[0031] The printed pattern of the single-sided circuit board is relatively simple. Generally, the method of screen printing is used to transfer the pattern, and then the printed board is etched, and some are produced by the photochemical method.

[0032] A double-sided circuit board is a printed board with conductive patterns arranged on the opposite sides. Obviously, the area of a double-sided circuit board is twice as large as that of a single-sided board...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com