High-impermeability capillary tube discharging plasma generator

A technology of discharging plasma and capillary tube, applied in the direction of plasma, electrical components, etc., can solve the problems of short circuit, insufficient bonding between insulating components, insufficient air tightness, etc., to increase the length of the channel, increase the sealing performance, and enhance the sealing performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The invention provides a capillary discharge plasma generator with high airtightness. Through the new design of the closed electrode and the design of the insulating parts, the inner airtightness of the generator is increased, and the guarantee for avoiding the internal short circuit is provided. The present invention will be further described in detail below in conjunction with specific embodiments and drawings, which are explanations of the present invention rather than limitations.

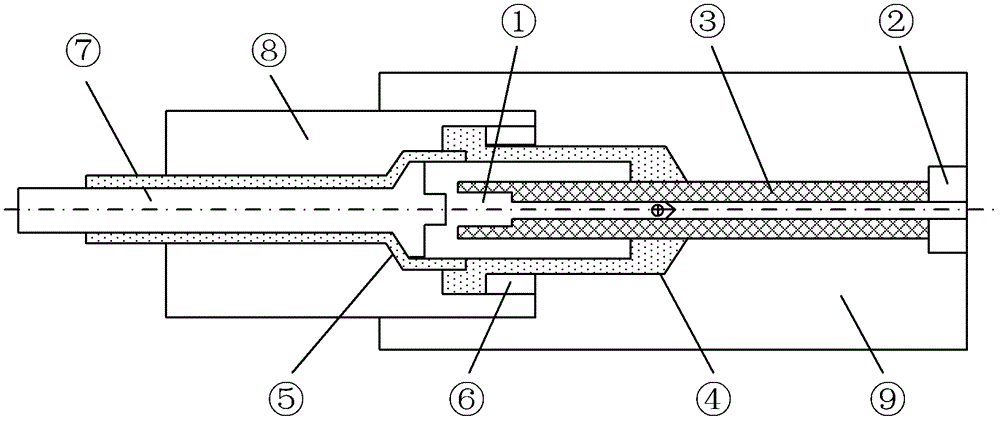

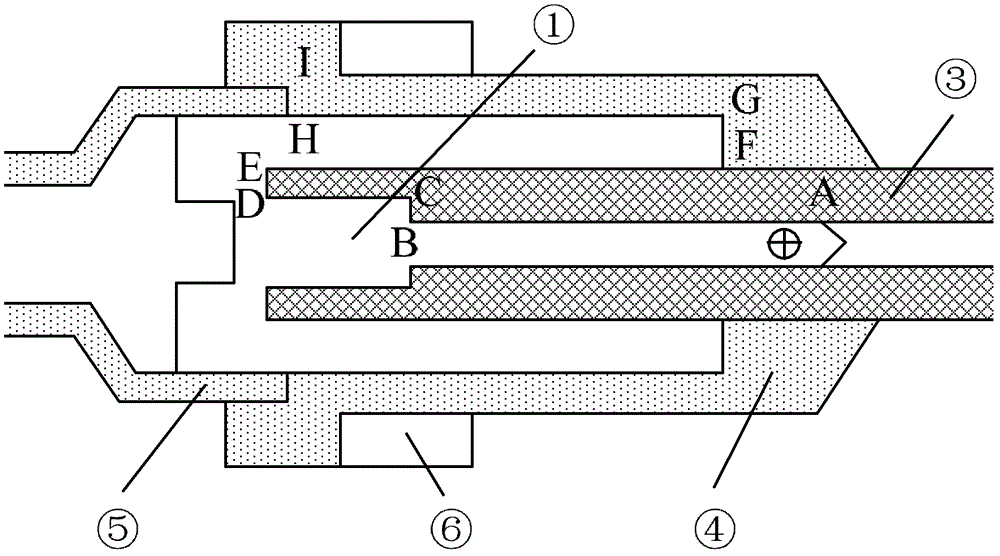

[0022] see figure 1 , figure 2 , a highly airtight capillary discharge plasma generator, comprising a nozzle electrode 2 and a closed electrode 1 embedded in a capillary 3, the closed electrode 1 includes a central column that extends into the capillary 3 and closely fits the inner surface of the capillary 3, and The outer ring closely fits the outer wall of the capillary 3 , the center column is provided with a boss at the base, and the inner wall of the capillary is provided with a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com