Efficiently-cooling motor with axial flow draft fan

An exhaust fan and shaft technology, applied in cooling/ventilation devices, motors, electromechanical devices, etc., can solve the problems of difficult heat dissipation, low protection level, heavy weight, etc., and achieve the effect of increasing the air output and enhancing the cooling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

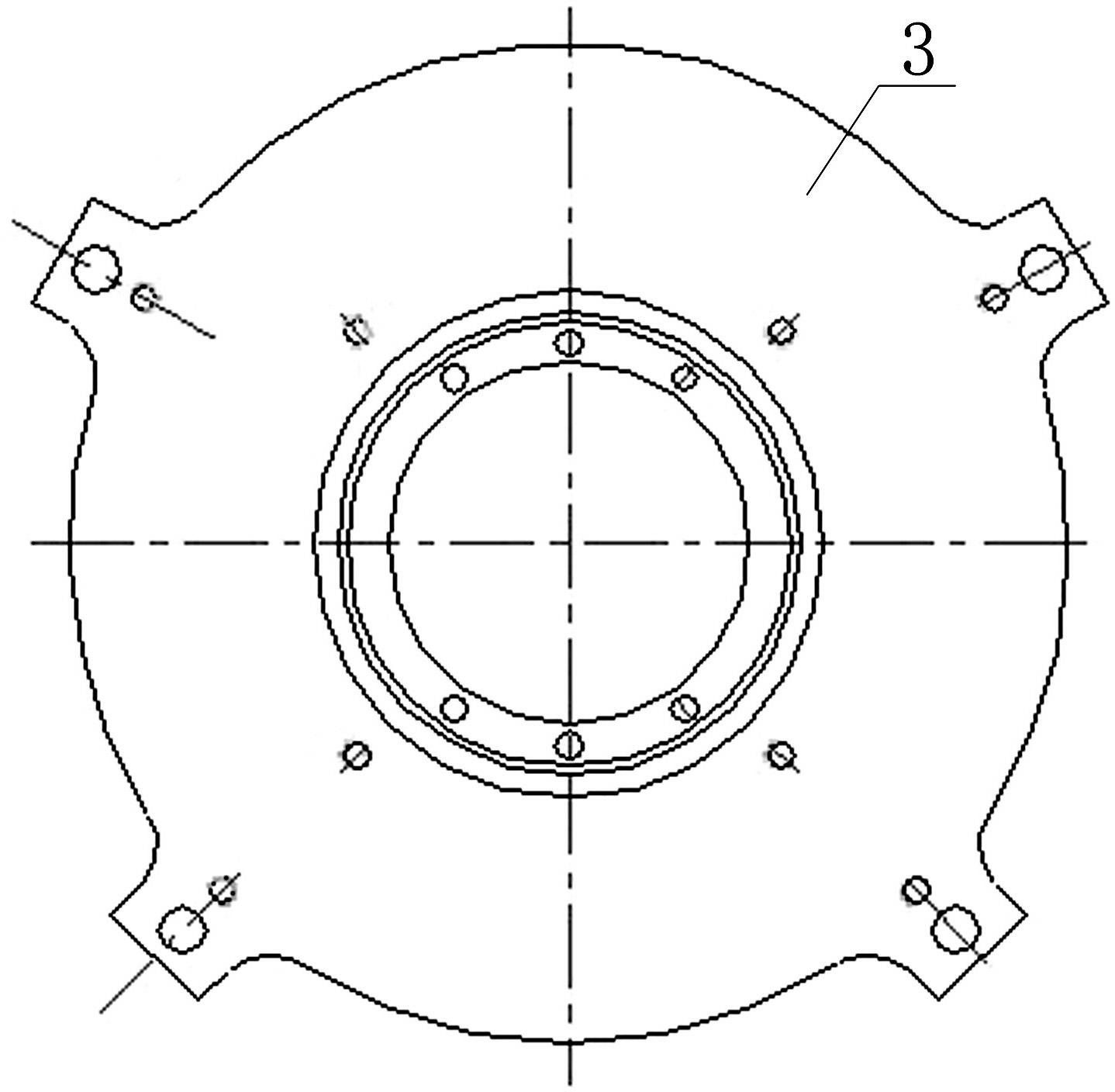

[0013] A high-efficiency cooling motor with an axial flow exhaust fan, including a stator assembly, a rotor assembly, a casing 1, a drive end cover 2, and a non-drive end cover 3; the drive end of the casing 1 is equipped with a first flange 4, The drive end cover 2 is connected to the drive end of the casing 1 through the first flange 4; the non-drive end of the casing 1 is equipped with a second flange 5, and the non-drive end cover 3 is connected to the casing through the second flange 5 The non-drive end of 1 is connected; the casing 1 is provided with several cooling fins 6 in the axial direction, and each cooling fin 6 is evenly arranged on the outer side of the casing 1 along the circumferential direction; the outer side of the cooling fin 6 is covered with a cylindrical windshield 7 One end of the cylindrical windshield 7 is fixed to the second flange 5; the outer side of the casing 1 and the inner side of the cylindrical windshield 7 jointly form the outer air duct 8 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com