Assembled single-phase reactor

An assembled, single-phase electrical technology, applied in the manufacture of inductors/transformers/magnets, circuits, transformer/inductor coils/windings/connections, etc., can solve the problem of large magnetic leakage, poor electromagnetic compatibility, and inconvenient changes in product capacity and technical characteristics, etc., to achieve the effect of low noise, stable performance, reduction of skin effect and eddy current loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

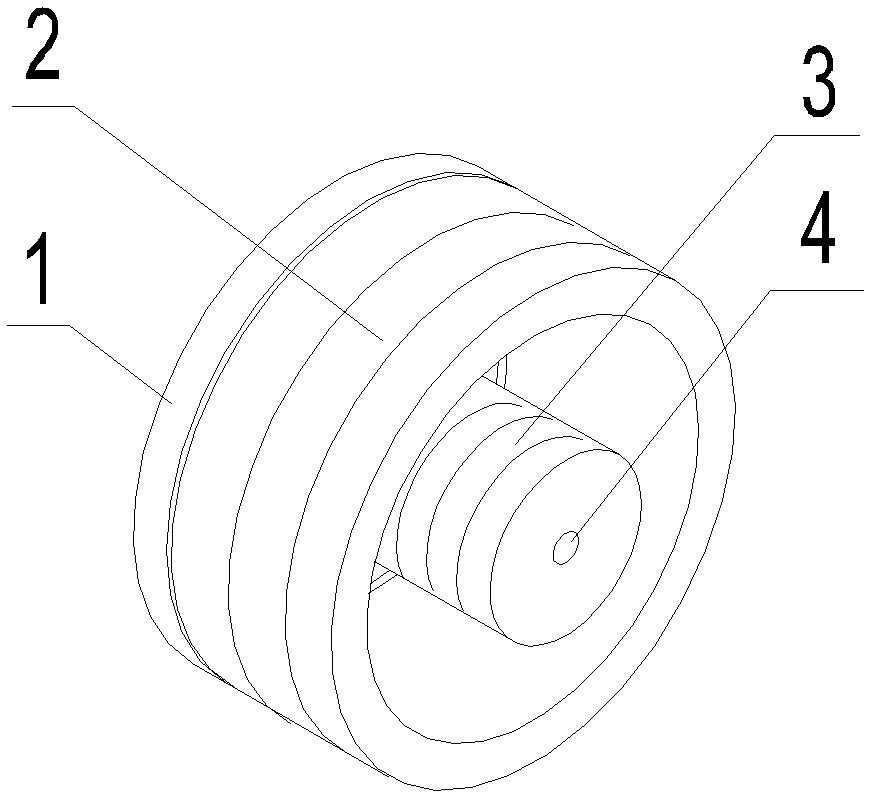

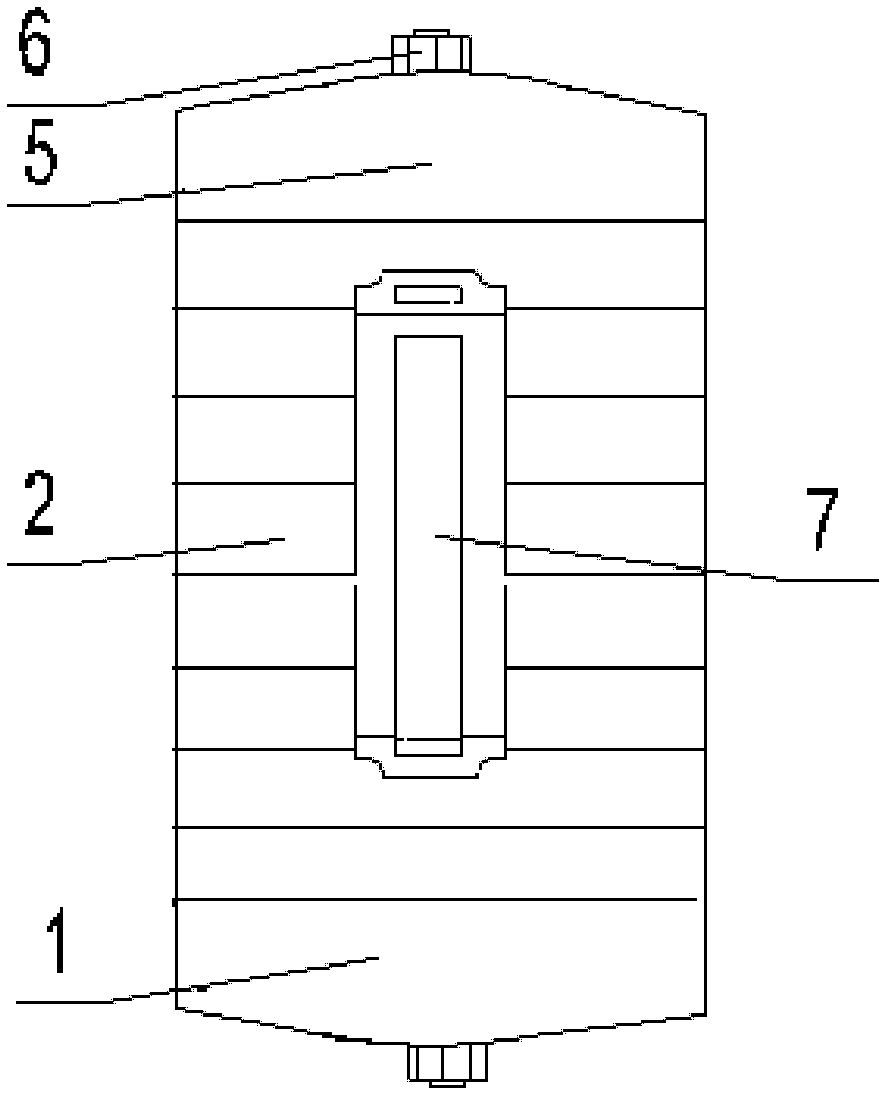

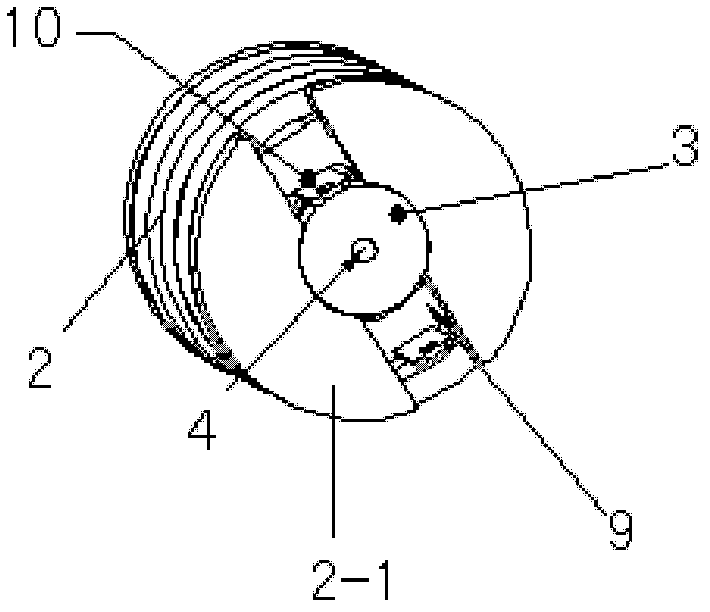

[0018] Concrete structure of the present invention is referring to accompanying drawing. The components made of soft magnetic powder metallurgy include a semicircular bottom plate, a magnetic ring shell and a magnetic column, which are assembled to form an assembled soft magnetic tank-type foil-wound single-phase reactor with a built-in foil coil in the tank shell. Soft magnetic powder metallurgy iron powder tank parts are made of iron powder or sendust material through pressure processing.

[0019] Depend on figure 1 , 2 It can be seen that the reactor as a whole is composed of a magnetic core 3, a magnetic ring shell (shielding wall) 2, upper and lower bottom plates 1, 5 to form a magnetic tank. The foil winding coil is put into the magnetic tank, and the whole magnetic tank is locked through the bolt 6 through the fixing hole 4 to complete the composition of the soft magnetic reactor. The height and design capacity can be adjusted freely by adopting the segmented structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com