GWIB (general way interface bus) high-temperature-resistant cable and preparation process thereof

A technology of high temperature resistance and cables, applied in the direction of cable/conductor manufacturing, insulated cables, bendable cables, etc., can solve the problems that the long-term working temperature can only reach 200 ℃, cannot meet the requirements of higher temperature working environment, and achieve weight Lightweight, small outer diameter, and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

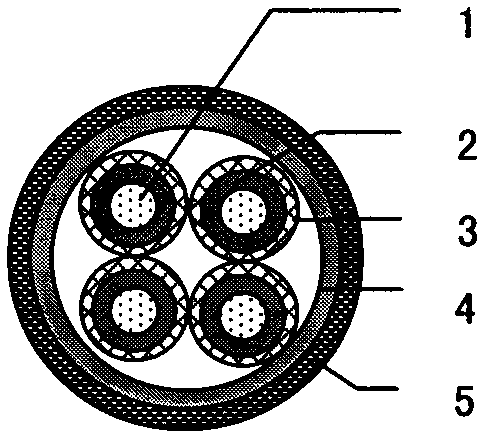

[0014] Control attached figure 1 Its structure is that the nickel-plated copper alloy wire conductor 1 stranded by a wire and cable stranding machine is surrounded by a two-layer polyimide composite tape (PTFE / PI / PTFE) inner insulating layer 2 wrapped by a wrapping machine. The outer periphery of the inner insulating layer is an outer insulating layer 3 of high-temperature-resistant alkali-free glass fiber woven by a braiding machine. The outer periphery of the outer insulating layer is a wrapping layer 4 wrapped with mica tape. Machine braided high temperature resistant non-alkali glass fiber braided sheath 5.

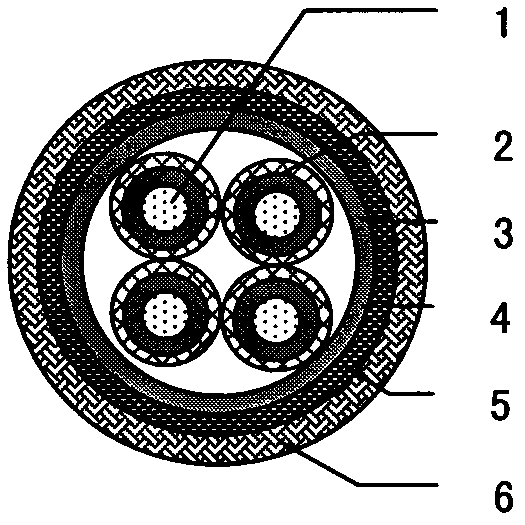

[0015] Control attached figure 2 Its structure is that the nickel-plated copper alloy wire conductor 1 stranded by a wire and cable stranding machine is surrounded by a two-layer polyimide composite tape (PTFE / PI / PTFE) inner insulating layer 2 wrapped by a wrapping machine. The outer periphery of the inner insulating layer is an outer insulating layer 3 of high-tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com