Electric welding safety goggles

A technology of goggles and electrode layers, applied in goggles, optics, instruments, etc., can solve the problems of failing to meet eye protection requirements, uneven viewing angle characteristics of liquid crystal displays, affecting the performance of welding goggles, etc., to protect eyes and body. The effect of health, improved viewing angle uniformity, and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

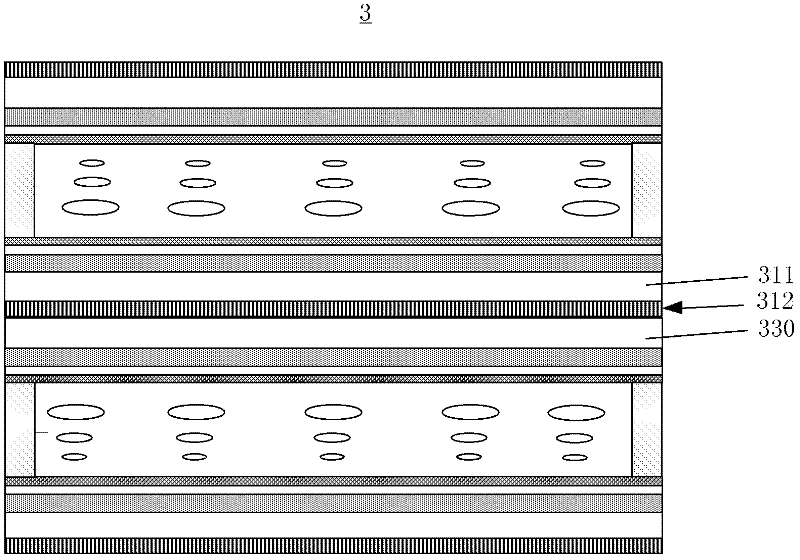

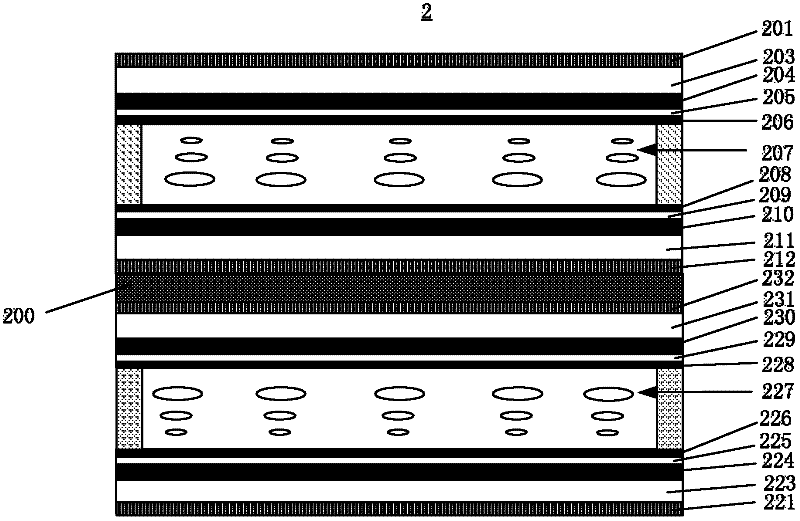

[0019] see figure 1 , which is a structural schematic diagram of the first embodiment of the electric welding goggles provided by the present invention. The welding goggles 2 include a first substrate 203, a second substrate 211, a third substrate 223, and a fourth substrate 231 stacked in sequence; a first liquid crystal layer 207 disposed between the first substrate 203 and the second substrate 211, and The second liquid crystal layer 227 is disposed between the third substrate 223 and the fourth substrate 231 . The first substrate 203 , the second substrate 211 , the third substrate 223 , and the fourth substrate 231 are all transparent substrates, which may be made of transparent glass, plastic, or quartz, and are not specifically limited here. The first liquid crystal layer 207 and the second liquid crystal layer 227 contain nematic liquid crys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com