Structure of reversing valve

A reversing valve and valve cavity technology, applied in the field of multi-position multi-way reversing valve structure, can solve problems such as damage to piston and cylinder end cover, wear of piston and cylinder end cover, short service life of piston cylinder, etc. The effect of avoiding collision and wear, increasing resistance and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

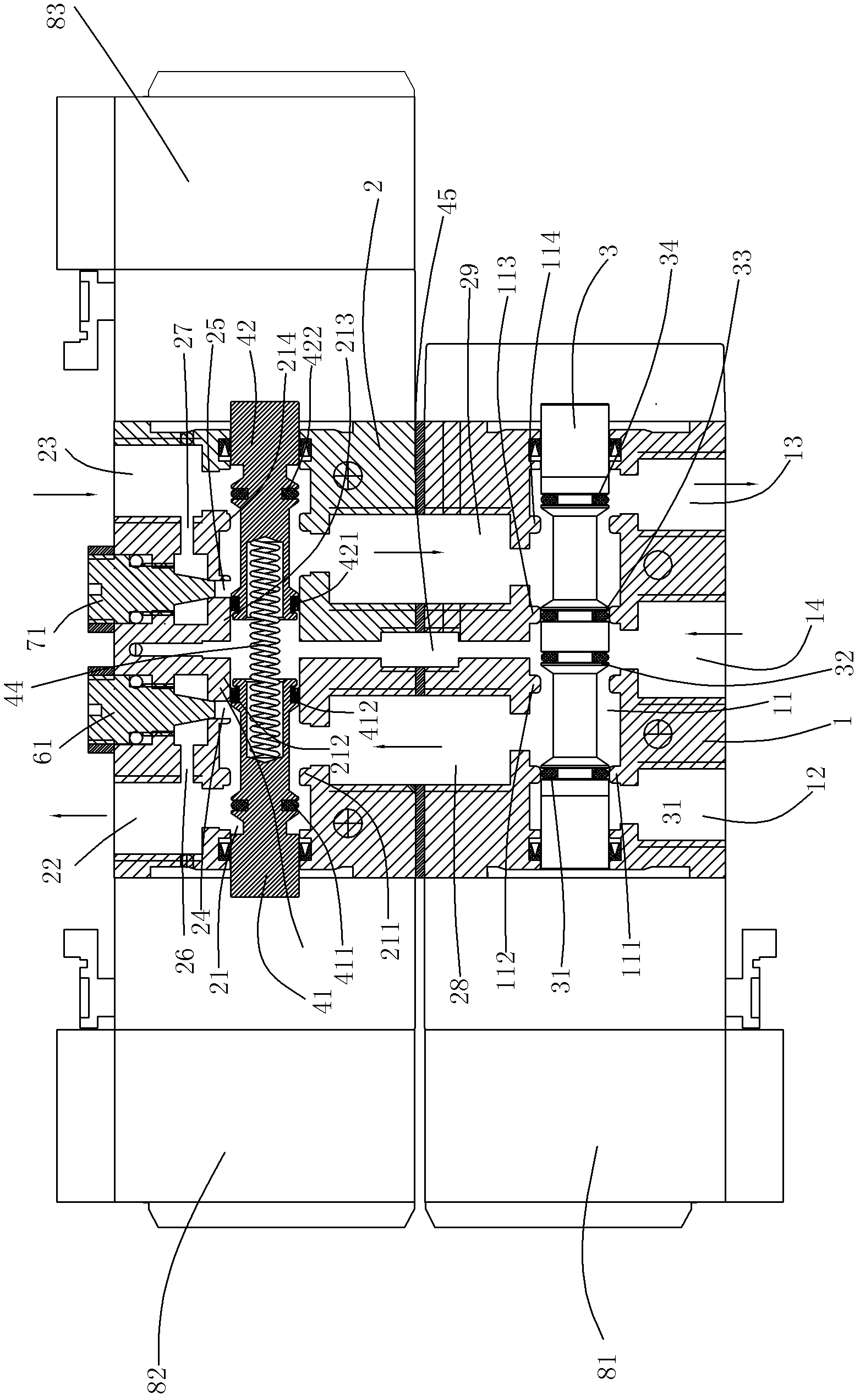

[0031] Such as figure 1 with figure 2 As shown, the reversing valve includes:

[0032] Considering the ease of processing and assembly, the valve body is designed as a split structure in this embodiment, including a first valve body 1 and a second valve body 2, the first valve body 1 and the second valve body 2 are connected together by screws . In this embodiment, the first valve body 1 and the second valve body 2 are superimposed and connected. The first valve body and the second valve body can also be connected side by side according to the installation space, such as Figure 5 Shown. And a sealing ring is arranged between the connecting channels of the two.

[0033] The above-mentioned first valve body 1 is provided with a first valve cavity 11 that accommodates the first valve stem 3 transversely therethrough, and a longitudinal first outlet 12 and an inlet 14 are spaced from left to right on the outer side wall of the first valve body. And the second outlet 13, the first o...

Embodiment 2

[0049] Such as image 3 , Figure 4 with Image 6 As shown, a second valve rod 9 is provided in the second valve cavity of the reversing valve structure to replace the second and third valve rods, and the fourth control valve 84 is drivingly connected to the second valve rod 9. The second valve body 2 is also provided with a first overflow hole 101 communicating the second valve cavity 21 and the first side flow hole 26, and a second overflow hole 101 communicating the second valve cavity 21 and the second side flow hole 27. The overflow hole 102; the first pressure piece 62 and the second pressure piece 72 are respectively shielded on the first overflow hole 101 and the second overflow hole 102; the first spring 63 and the second spring 64 are respectively looped around the first cone The two ends of the first spring 63 and the second spring 64 are in contact with the first pressure piece 62, the second pressure piece 72, the first tapered valve core 61, and the second tapered...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com