Speed reducer used for cooling tower

A technology for reducers and cooling towers, which is applied to components with teeth, transmission boxes, etc., can solve the problems of reducing the operating life of the reducer, complicated production and processing technology, and increasing processing costs, so as to increase operational reliability and safety. , reduce vibration and abnormal wear, and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

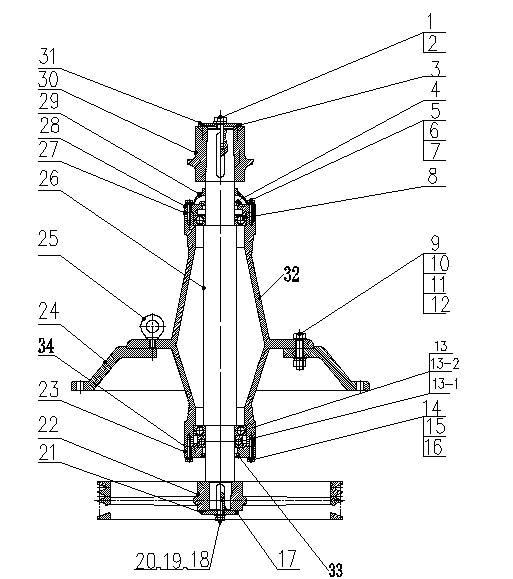

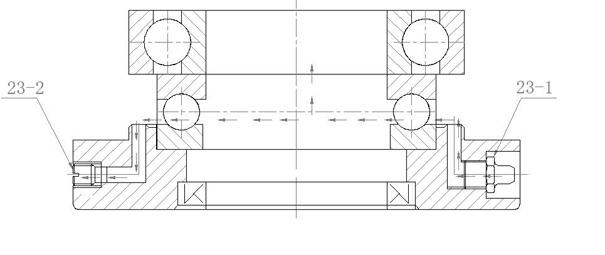

[0021] Such as figure 1 As shown, the cooling tower reducer according to the present invention includes a box body 32 , a base 24 and a drive shaft 26 . The base 24 is in the shape of a flange, and is provided with a lifting ring 17 for easy transportation, and forms a detachable connection with the box body 32 through the hexagonal bolt 9, the hexagonal nut 12, wherein between the hexagonal bolt and the box body 32, the hexagonal nut 12 A flat washer 10 and a spring washer 12 are arranged between the base 24 .

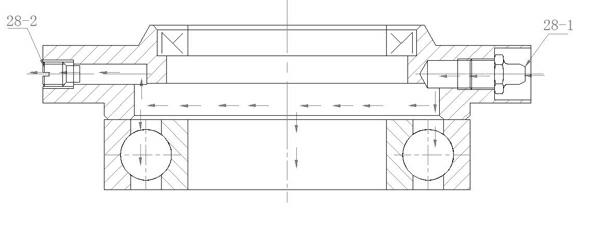

[0022] The top of the base 24 is used as the upper bearing seat, and the ball bearing 8 is installed inside. The upper end cover 28 for positioning the upper ball bearing 8 is fixed on the top of the box body 32 by the hexagonal bolt 5, and there is a gap between the hexagonal bolt 5 and the upper end cover 28. Spring washers 6 and flat washers 7 are provided. A water shield 29 is also provided on the top of the aforementioned upper end cover 28 , and the water shi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com