Pretensioning clamp for heat treated steel bars with high ratio of tensile strength to yield point and application method thereof

A technology of steel bars and fixtures, applied in the processing of building materials, building reinforcements, structural elements, etc., to achieve the effects of high anchorage efficiency coefficient, prevention of premature fracture, and reliable self-anchoring performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

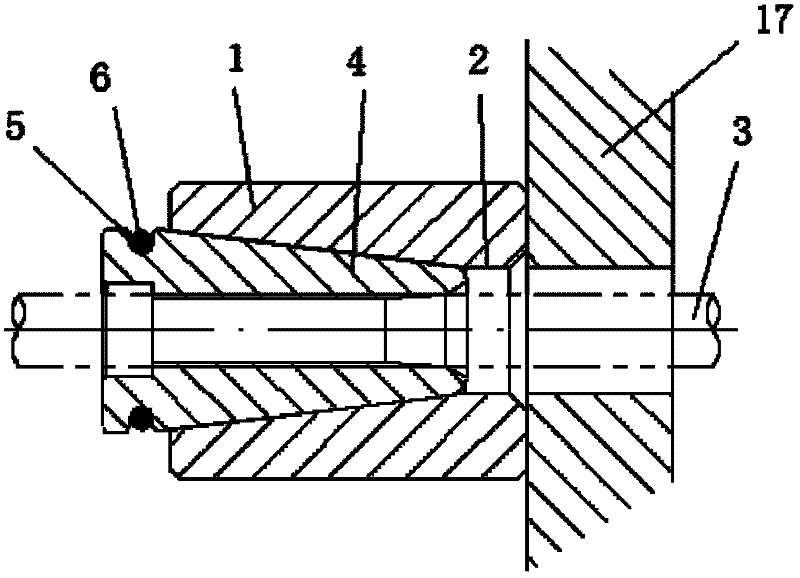

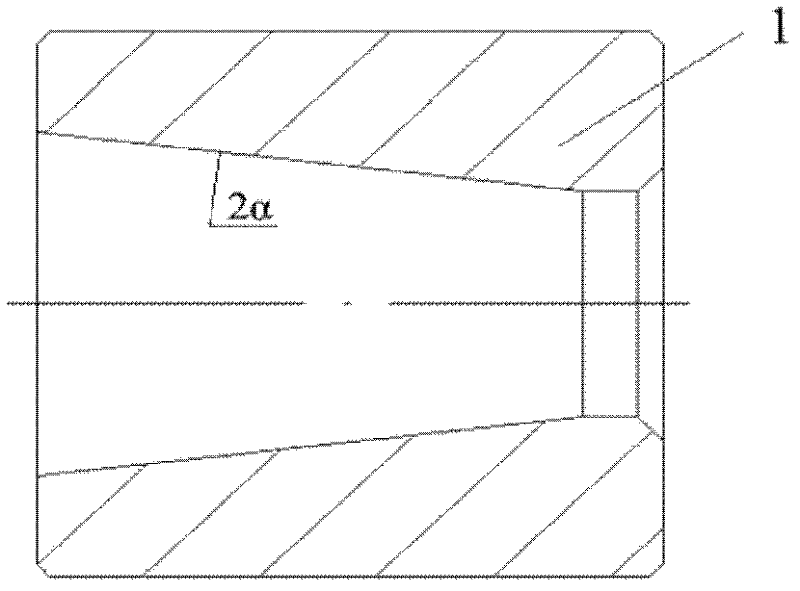

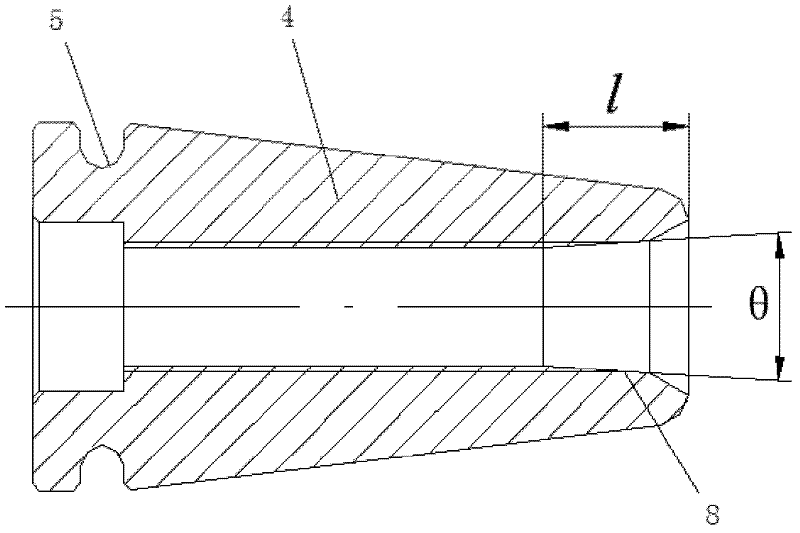

[0025] Such as figure 1 , figure 2 As shown, the present embodiment includes a cylindrical anchor ring 1, the inner diameter of the anchor ring 1 is a tapered hole 2, the cone angle 2α of the tapered hole 2=14°, and the cone angle can vary within 11°-15°. In the tapered hole 2, three clips 4 (such as image 3 , Figure 4 As shown), the conical angles of the outer cone surfaces of the combined three clips 4 are 5' to 30' larger than the conical angles of the taper holes 2, and the outer walls of the big ends of the combined three clips 4 are provided with a circle of grooves 5 , the groove 5 is provided with an O-ring 6 that connects the three clips 4 into one (such as figure 1 shown). Such as Figure 5 As shown, the inner walls of the three clips 4 are provided with screw teeth 7, the radial section of the screw teeth 7 is zigzag, the tooth tip angle of the screw teeth 7 is γ, 76°≤γ≤78°, the front edge of the screw teeth 7 The angle is β, 69°≤β≤71°, and the pitch of the...

Embodiment 2

[0032] Such as Image 6 As shown, this embodiment includes a cylindrical anchor ring 9 , and a section of tapered hole 10 and a section of straight hole 11 connected with the tapered hole 10 are arranged in the anchor ring 9 . The port of the straight hole 11 is provided with three inner convex bayonets 12 (such as Figure 7 , Figure 8 shown), in the taper hole 10, three clips 4 that are identical to each other at 120° are provided in the taper hole 10, and grooves 5 are set on the outer wall of the big end of the three clips 4, and O is arranged in the groove 5. Type sealing ring 6. A spring 13 is arranged at the end of the large end of the three clips 4, and a gland 14 is arranged at the other end of the spring 13. The port of the gland 14 is provided with three pairs of bosses that cooperate with the inner convex bayonet 12 on the anchor ring 9. 15, 16 (such as Figure 9 , Figure 10Shown), and each pair of bosses 15,16 is a high, a low. When in use, the spring 13 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pitch | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com