Developing apparatus, process cartridge and image forming apparatus and assembling method of developing apparatus

A developing device and developer technology, which are applied in the direction of electric recording process applying charge pattern, equipment for applying electric recording process of charge pattern, electric recording technique, etc., can solve the problems of developer leakage and sealing performance reduction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

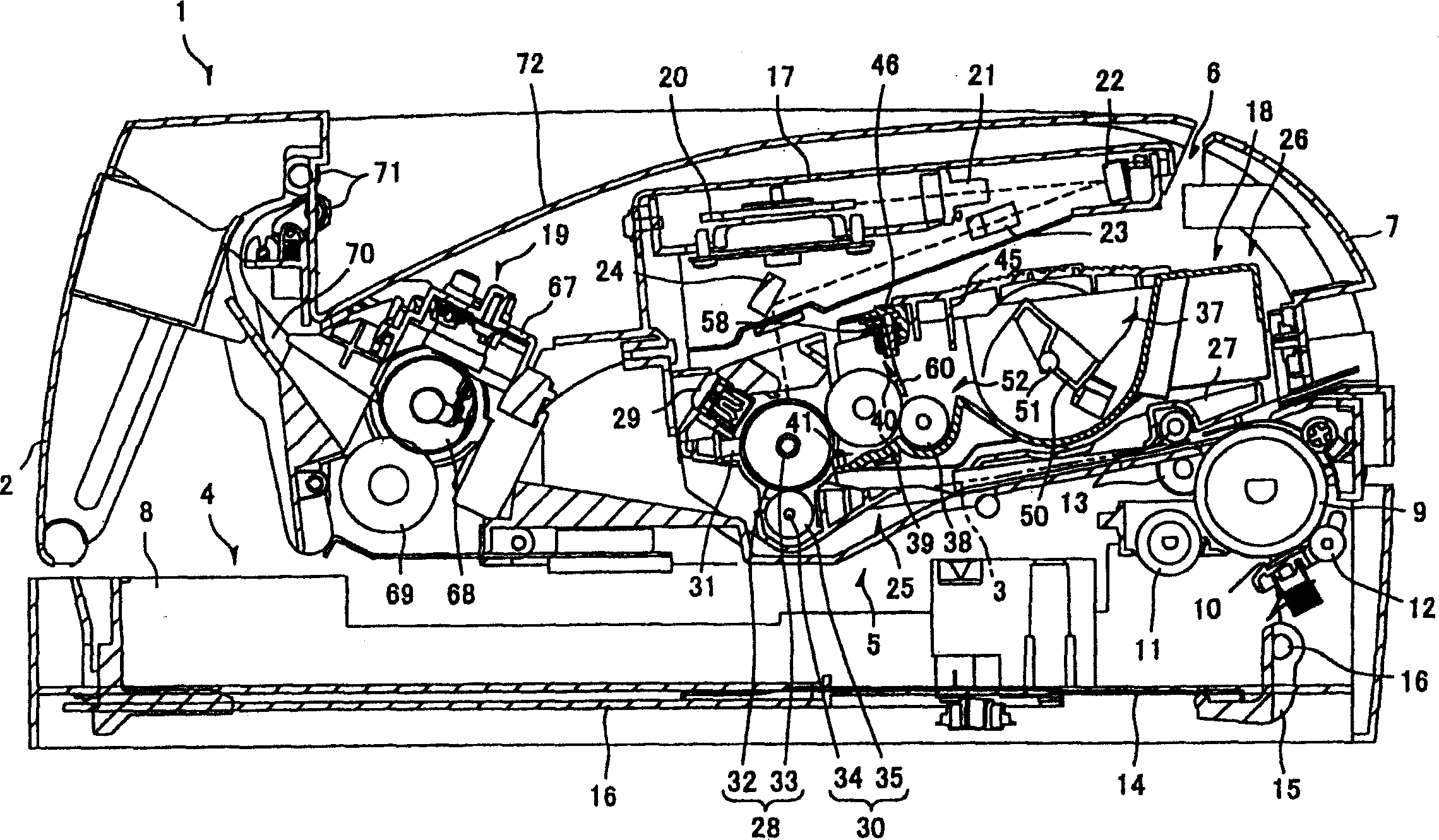

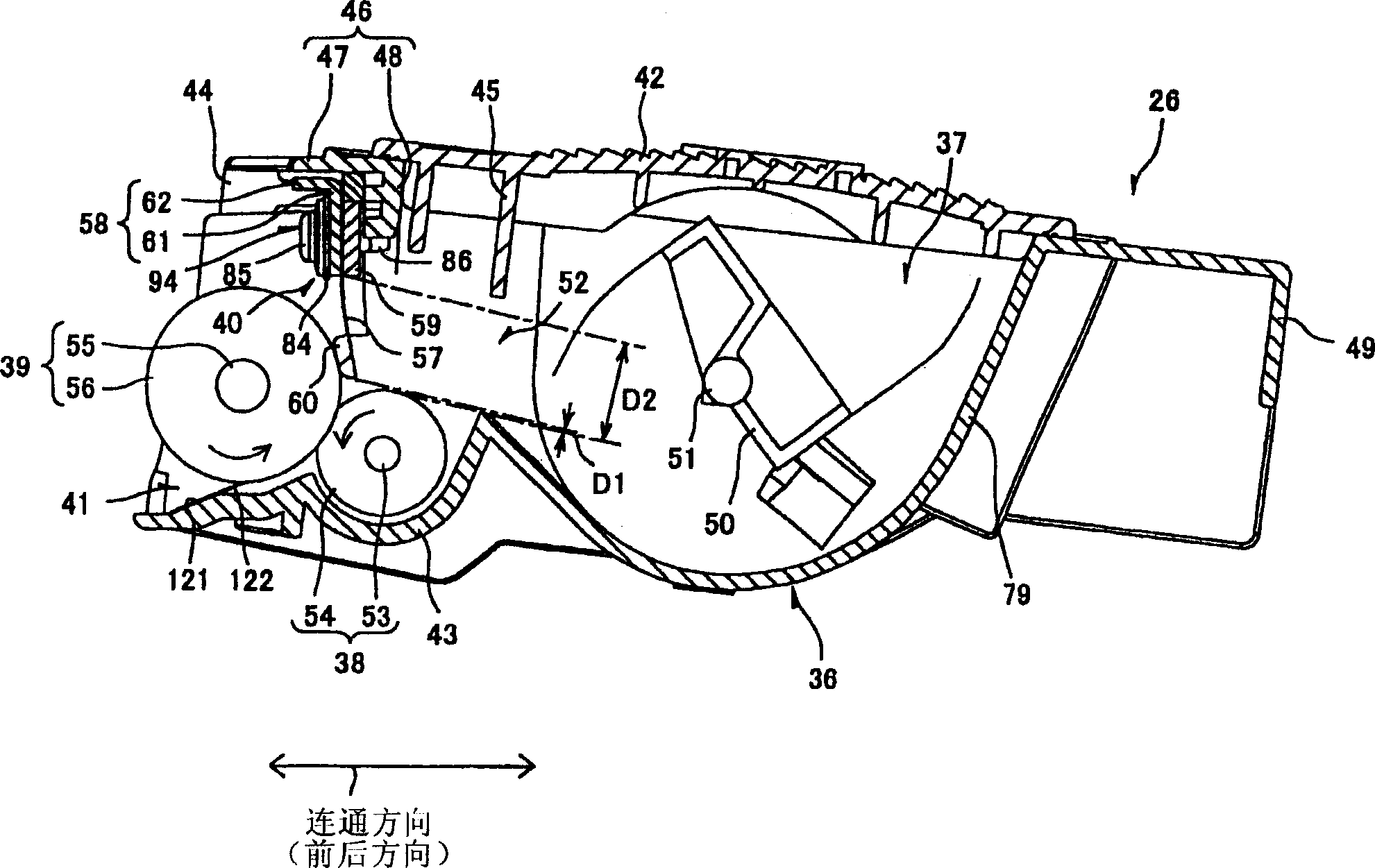

no. 1 Embodiment approach

[0111] Also, in this example, the squeegee inner seal 87 is attached to the leaf spring member 57 by the double-sided tape 90, the squeegee assembly 40 with the squeegee inner seal 87 is assembled to the squeegee assembly part 46, and the double-sided tape 90 is attached to After the front assembling part 48 of the scraper assembly part 46 is partially pasted on the inner seal 87 of the scraper with respect to the double-sided tape 90, the scraper assembly 40 may be assembled to the scraper assembly 46. First embodiment: Second example

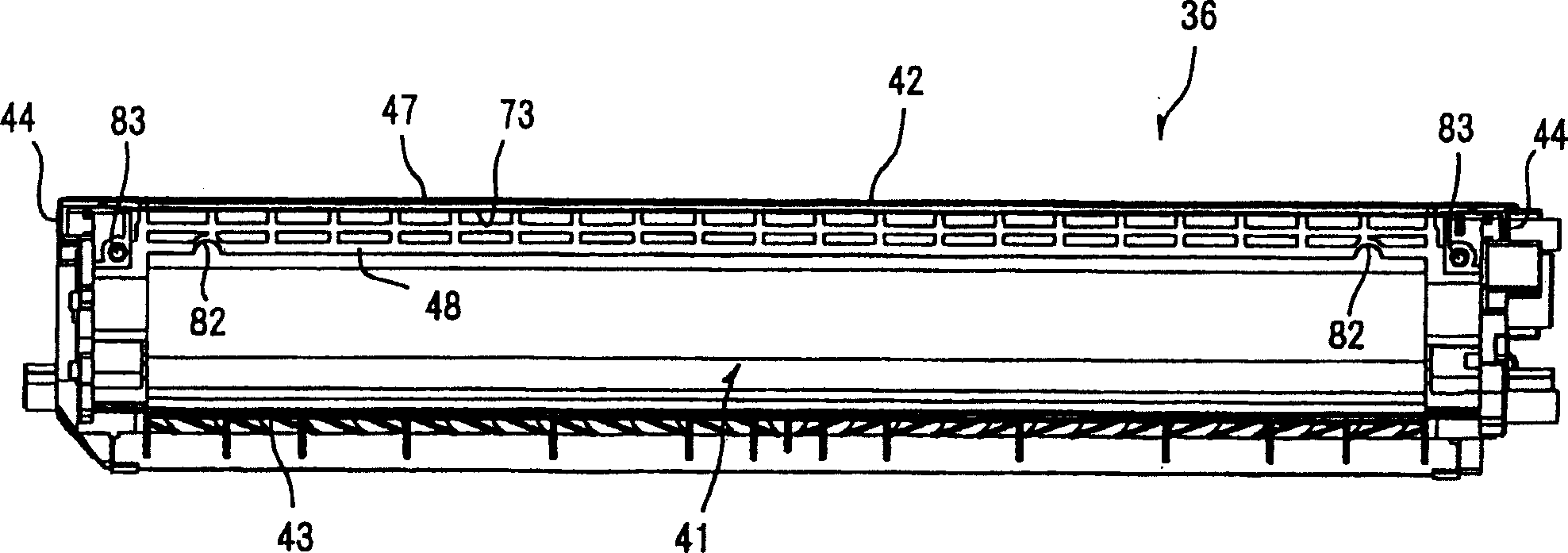

[0112] Picture 11 It is a front view showing another example of the doctor blade assembly 40. And, the parts corresponding to each part are Picture 11 The same reference numerals are assigned, and the description thereof will be omitted below.

[0113] At that Picture 11 In the scraper assembly 40 shown, on the back of the leaf spring member 57, the entire area on the lower end side of the leaf spring member 57 with respect to the reinforcing ...

no. 2 Embodiment approach

[0120] In this example, as the elastic adhesive 150, Super X (Japanese: スパ-X, manufactured by Quick-acting Adhesive Co., Ltd. (manufactured by Semeden Co., Ltd.), a registered trademark) was used. Adopt the method of bonding the leaf spring part 57 of Super X, the reinforcing plate 59 and the seal 87 in the scraper, preferably as Figure 16 As shown, after applying Super X to both ends of the reinforcing plate 59 in the longitudinal direction, it is left for ten minutes and then bonded separately in a semi-dry state. Therefore, after applying Super X to the both ends of the reinforcing plate 59 in the longitudinal direction and leaving it for a few minutes (for example, 2 minutes), compared with the case where the doctor blade assembly 40 and the blade inner seal 87 are bonded to each other, the developing cartridge 26 It becomes easy to peel off during reuse, which can improve its reusability. The second embodiment: the first example

[0121] Such as Figure 17 As shown, in the de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com