Punching machine head

A machine head and collet technology, applied in the direction of presses, heat exchange equipment, manufacturing tools, etc., can solve the problems of high scrap rate, heat sink installation does not meet the heat dissipation requirements of magnetron, and mismatches, so as to improve the success rate , Reduce production precision, improve the effect of qualified rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

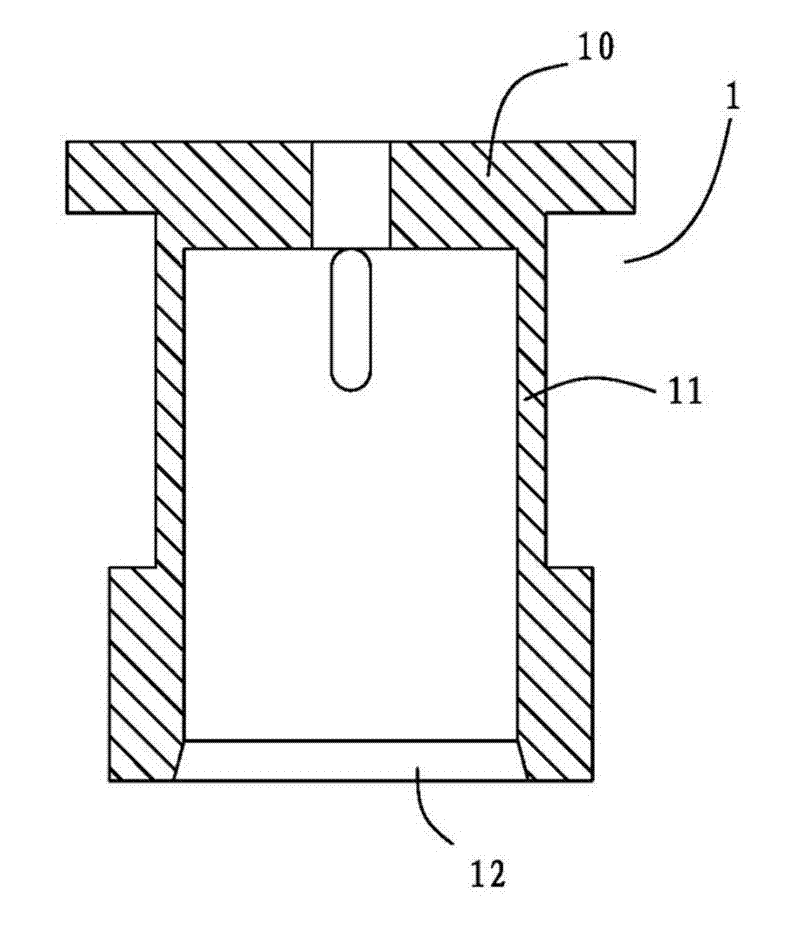

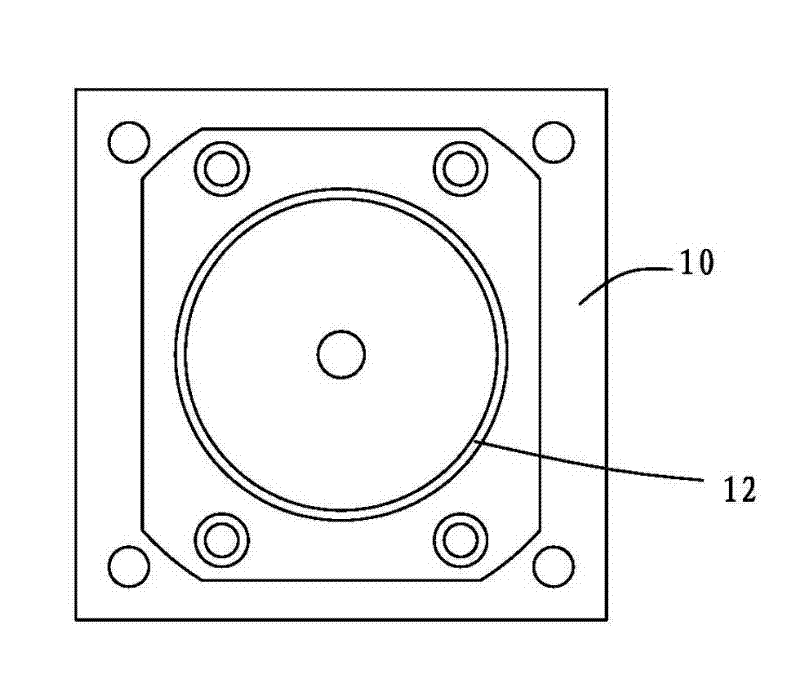

[0019] A stamping machine head, including a collet sleeve 1 and a collet 2, combined with figure 1 , figure 2 , The collet sleeve 1 includes a mounting surface 10 , a ring of walls 11 formed around the mounting surface 10 , and a ring of lower ports 12 surrounded by the wall 11 .

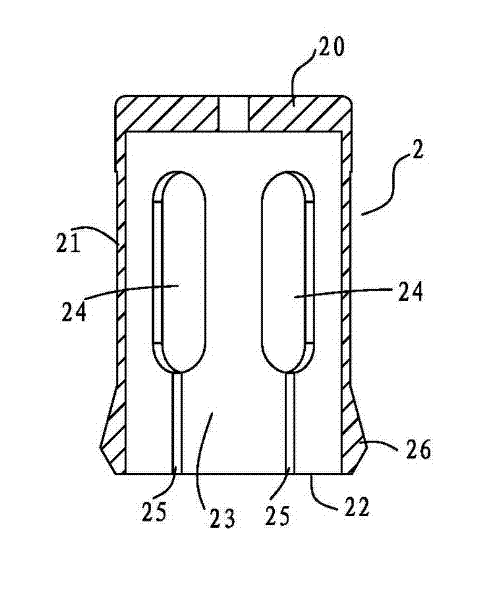

[0020] combine Figure 3 to Figure 5 , the chuck 2 includes a connecting end face 20, a circle of side walls 21 formed around the periphery of the end face 20, and a clamping port 22 surrounded by the side wall 21, and the inner chamber 23 of the chuck 2 passes through the clamping port 22 outward Extending, the side wall 21 is provided with six long grooves 24 penetrating the inner surface and the outer surface of the side wall side by side along the circumferential direction, the long grooves 24 are separated from each other, and the long grooves 24 extend alon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com