IGBT (Insulated Gate Bipolar Translator) driving circuit for novel high-frequency high-voltage switching power supply

A high-frequency, high-voltage, switching power supply technology, applied to electrical components, output power conversion devices, etc., can solve problems such as small power factor, long response time, and susceptibility to interference, and achieve suppression of high-frequency parasitic oscillations, turn-on and turn-off Low power consumption and reduced mutual interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

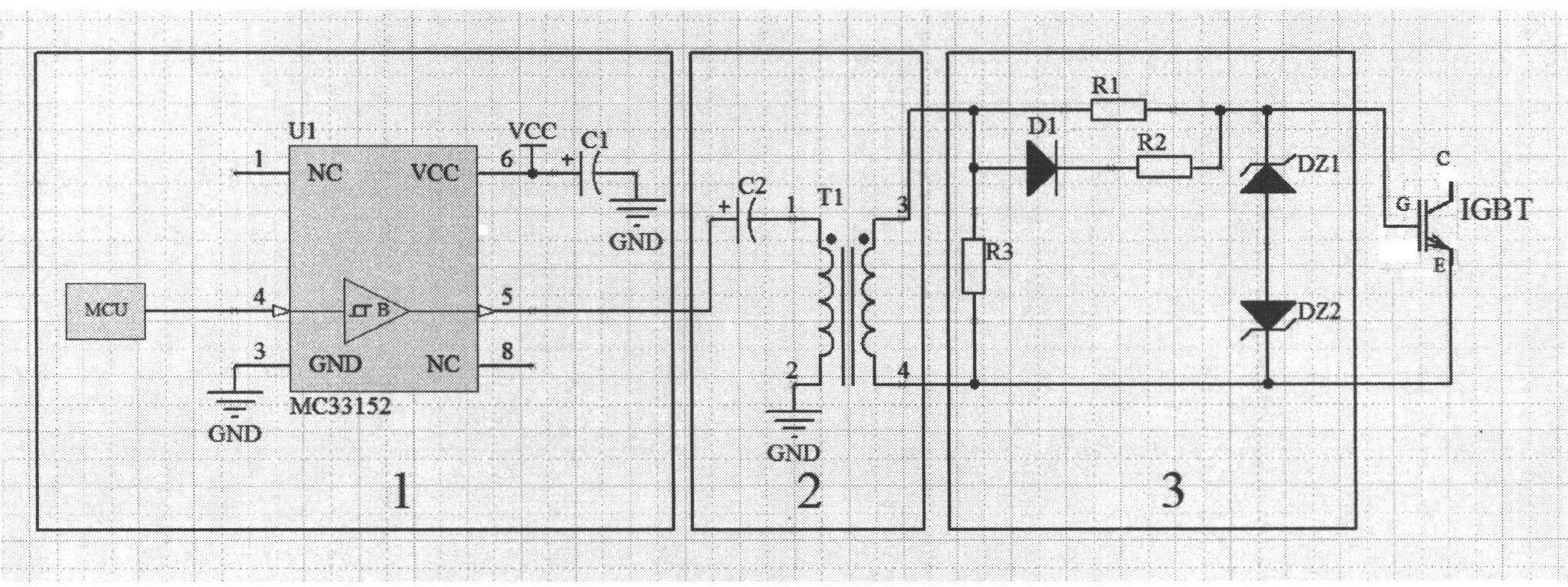

[0010] A novel IGBT drive circuit for high-frequency and high-voltage switching power supplies of the present invention is shown in Figure 1, comprising a switch control circuit (1), a pulse transformer isolation circuit (2) and a voltage stabilizing circuit (3); the front-end controller MCU generates the IGBT The driving signal is input to the high-speed dual-channel non-inverting driver MC33152; the output terminal is connected to the primary circuit of the pulse transformer isolation circuit, which is isolated and transmitted to the secondary circuit through the pulse transformer isolation circuit; the output of the pulse transformer secondary circuit is connected to the input terminal of the voltage stabilizing circuit, The output terminals of the voltage stabilizing circuit are respectively connected to the gate and emitter of the IGBT.

[0011] In this embodiment, the above-mentioned switch control circuit (1) is composed of front-end controller MCU, power supply VCC, cap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com