End cover type sliding bearing of high-speed motor

A technology of sliding bearings and high-speed motors, which is applied in the direction of electric components, casings/covers/supports, electrical components, etc., can solve problems such as oil leakage, achieve the effect of easy assembly and prevent oil leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

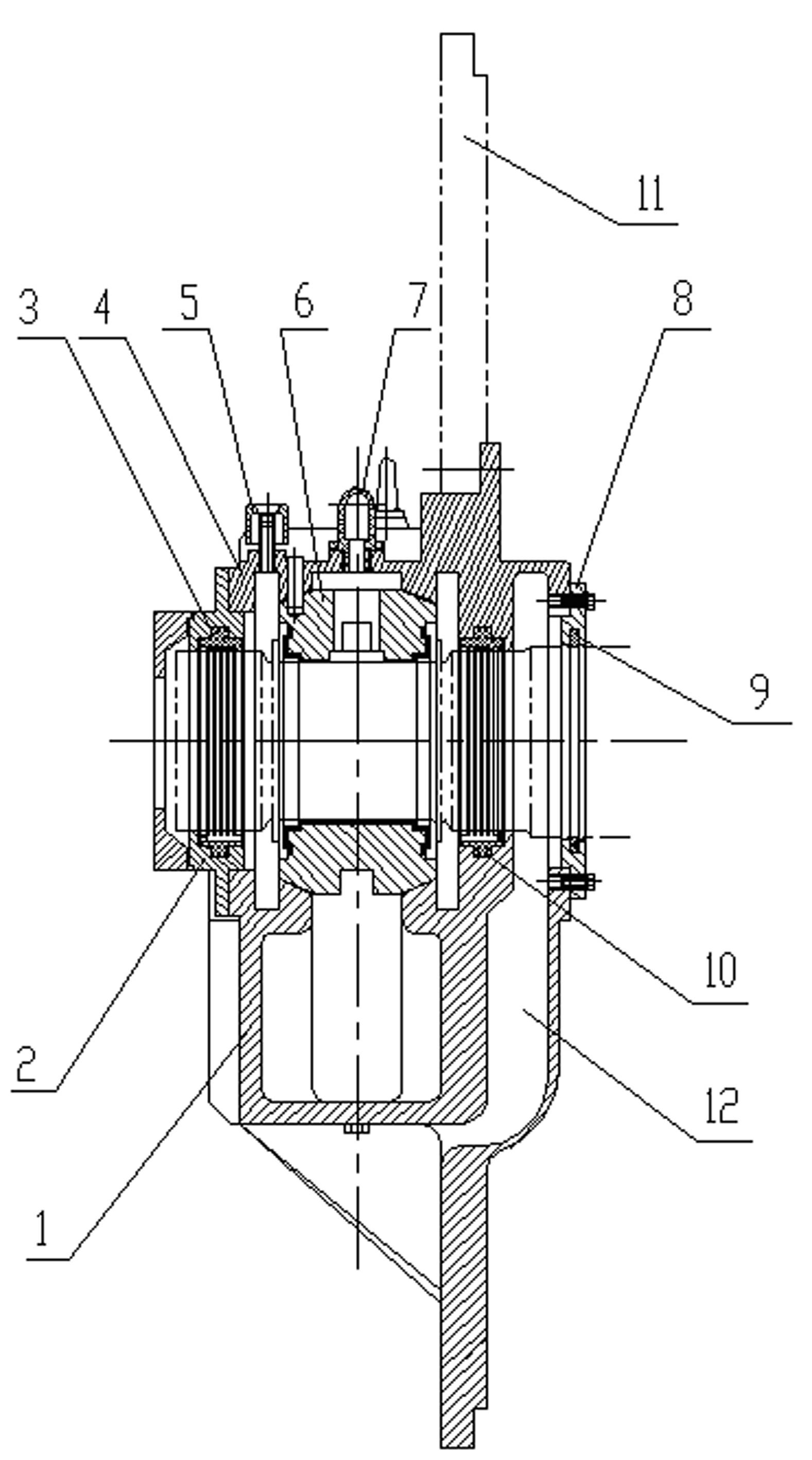

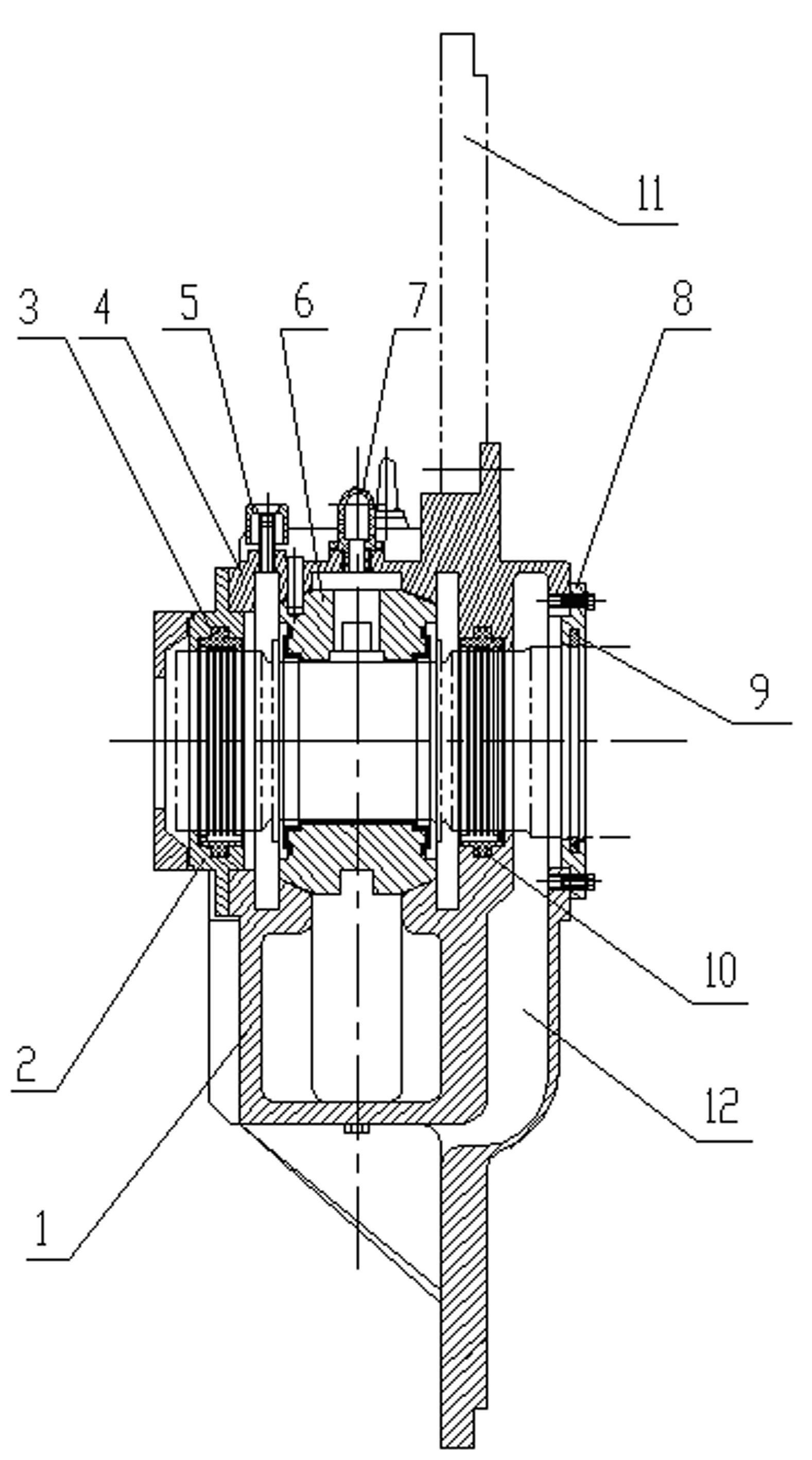

[0010] like figure 1 As shown, in the embodiment of a high-speed motor end cover type sliding bearing provided by the present invention:

[0011] The high-speed motor end cover type sliding bearing includes bearing housing 1, bearing outer cover 2, bearing upper cover 4, valve 5, bearing bush 6, oil inlet pipe 7, bearing inner cover 8 and sealing ring 3, sealing ring 9 and sealing ring 10 . The upper bearing cover 4 and the bearing box 1 are in half structure, and the lower half of the bearing box 1 and the motor end cover are combined into one; a lower cavity is provided in the side wall of the bearing box 1 near the motor side, and the lower cavity Leading to the bottom of the motor shaft, there is a groove near the inner diameter of the side wall of the bearing bush 5, and a floating sealing ring 10 is built in; an upper cavity corresponding to the lower cavity is provided in the side wall of the bearing upper cover 4 near the motor side, The upper cavity leads above the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com