Elastic piece structure of core disk-pressing module

A shrapnel and core technology, applied in the field of optical disc players, can solve the problems of high component cost, complex component processing technology, complex structure, etc., and achieve the effects of low cost, simple shape and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The shrapnel structure of the movement pressure disc module of the present invention has a simple structure, and its advantages over the previous technical solutions are: relatively simple shape, simple processing technology, certain advancement, small volume, and low cost.

[0016] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

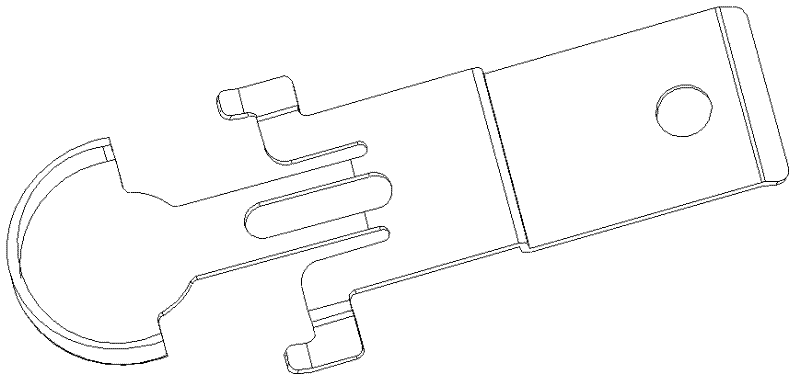

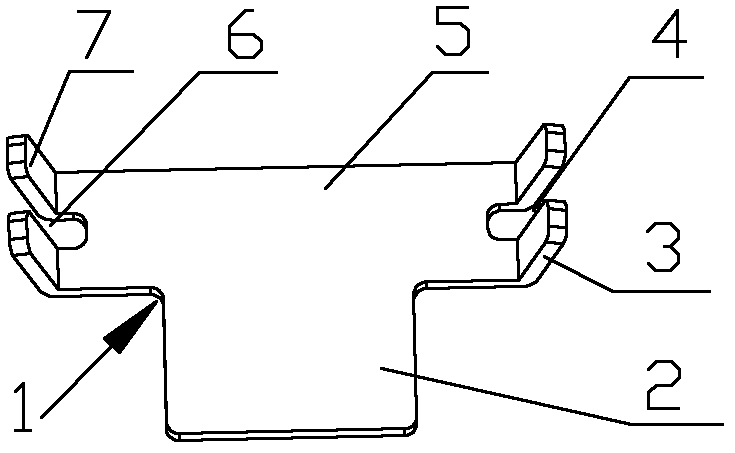

[0017] see image 3 , represents the structure of a preferred embodiment of the structure of the movement disc module shrapnel (hereinafter referred to as the shrapnel) of the present invention. The shrapnel is a shrapnel made of metal material or plastic material, and has a left-right symmetrical structure. The structure includes a T-shaped bottom wall 1, and the T-shaped bottom wall 1 is provided with a rear mounting part 5 and a front press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com