Flue gas content laser on-line detection method and system

A technology of gas content and detection system, which is applied in measurement devices, color/spectral property measurement, material analysis by optical means, etc., can solve the problem that optical gas sensors cannot achieve accurate measurement, and achieve easy maintenance and work reliability. High, ensure the effect of normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

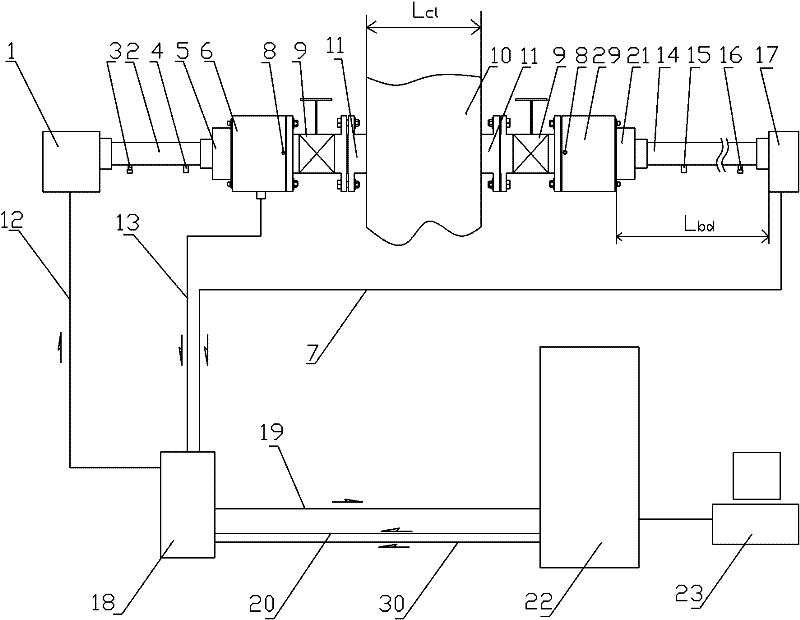

[0042] see figure 1 and figure 2, the flue gas content laser on-line detection system of the present invention adopts through-beam optical measurement, mainly including a light drive unit, a light emission unit, a light signal detection unit, an electrical signal transmission unit, an instrument air distribution unit, a central control cabinet, and an industrial computer Wait.

[0043] The optical drive unit is used to generate modulated laser light, including a function generator and a dual-frequency modulation signal synthesis circuit, a semiconductor laser, a semiconductor laser drive circuit, and a semiconductor laser temperature control circuit; after the system is powered on, the function generator generates two signals of different frequencies , These two signals are respectively sent to the semiconductor laser drive circuit and the subsequent circuit for signal processing, demodulation, and sampling. After the semiconductor laser drive circuit synthesizes the signal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com