Annular soil groove testing stand

A ring-shaped soil tank and test bench technology, which is applied in the testing of machines/structural components, measuring devices, instruments, etc., can solve the problems that the test bench cannot perform agricultural machinery reliability tests, shorten the test and research cycle, and reduce labor intensity , the effect of reducing occupancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0095] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

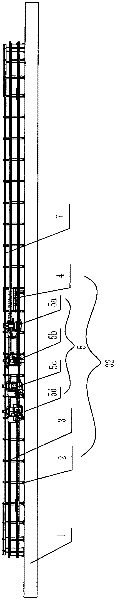

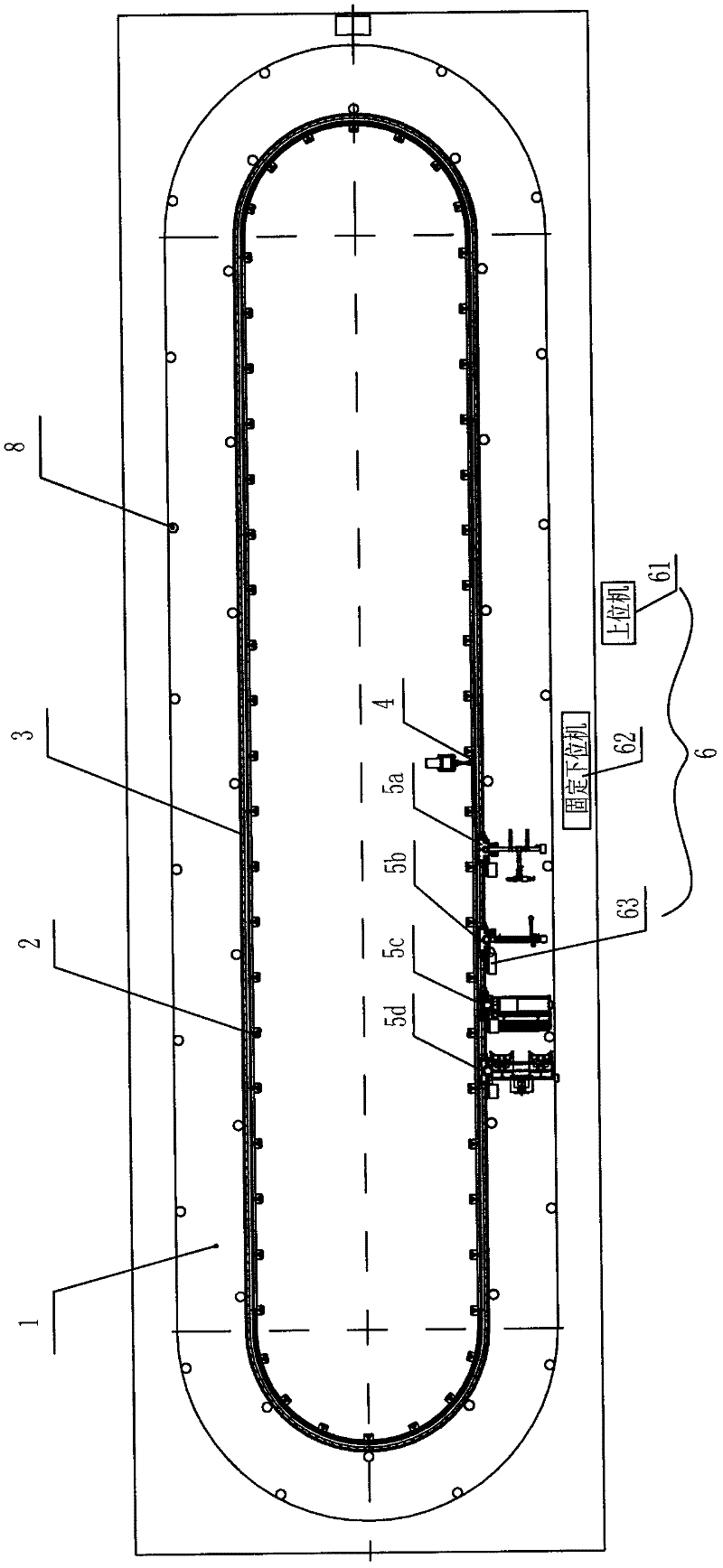

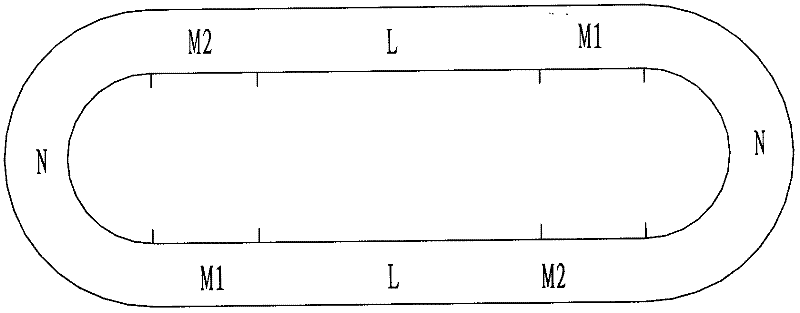

[0096] see Figure 1A and Figure 1B , Figure 1A It is a schematic diagram of the structure of the annular soil tank test bench according to an embodiment of the present invention, Figure 1B for Figure 1A top view. The annular soil tank test bench of the present invention is mainly used for performance tests and reliability tests of agricultural machinery and working parts. It includes an annular soil tank 1, a walking system 02, a measurement and control system 6, and a power system 7. The measurement and control system 6 and the power system 7 are connected to the walking system 02. The annular soil tank 1 includes a straight line segment and an arc A closed soil tank connected in sequence, the walking system 02 includes a vertical double-layer running track 3, a traction system 4 and at least one trolley 5, the running...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com