Dynamic safety-monitoring and alarming system and method in building (structure) mechanical-dismantling process

A technology of dynamic monitoring and alarm system, applied in electromagnetic measuring devices, electrical/magnetic solid deformation measurement and other directions, can solve the problems of poor safety assurance effect, backward safety monitoring methods, passive safety assurance measures, etc., and achieves simple and convenient installation and operation. Improved reliability and enhanced overall reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

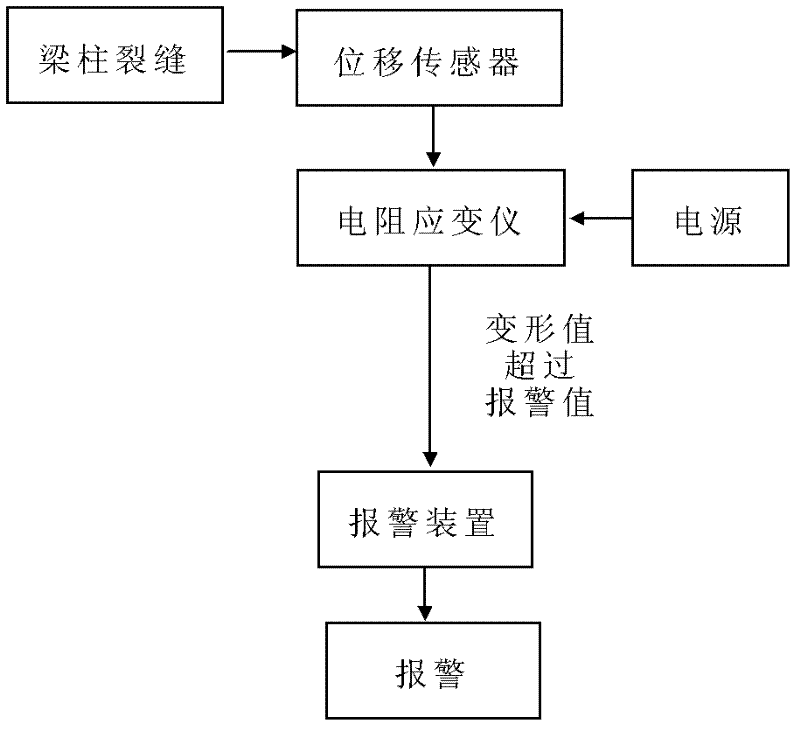

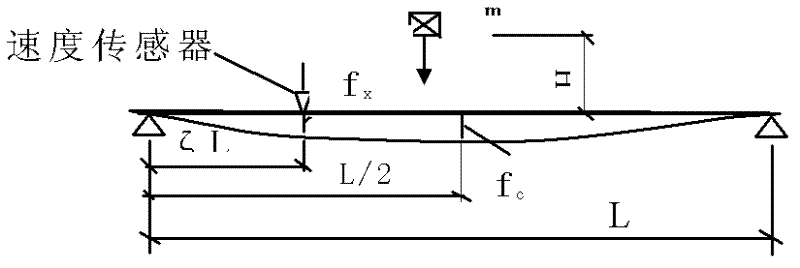

[0040] Theoretical basis and implementation method of the present invention are as follows:

[0041]1. Safety requirements for mechanical demolition of buildings (structures)

[0042] 1 The construction of mechanical demolition of buildings (structures) uses mechanical equipment to remove beams, walls, and columns from top to bottom layer by layer in sequence. After the concrete on the floor is removed, the steel bars are cut with hydraulic shears. According to construction experience and on-site observation, this mechanical demolition method is relatively safe for the column structure during the construction process, while the beam during the demolition process is in a cantilever state, and the safety factor is low. Therefore, the mechanical demolition process of buildings (structures) The dynamic safety monitoring focuses on beam stability.

[0043] 2 In the process of mechanical demolition of buildings (structures), if the building part is damaged or the remaining structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com