Construction method of all-casing rotary jet grouting pile

A construction method and technology of spraying piles, applied in sheet pile wall, foundation structure engineering, construction, etc., can solve problems such as waste, and achieve the effects of easy installation and operation, reduced penetration, and reliable pile formation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

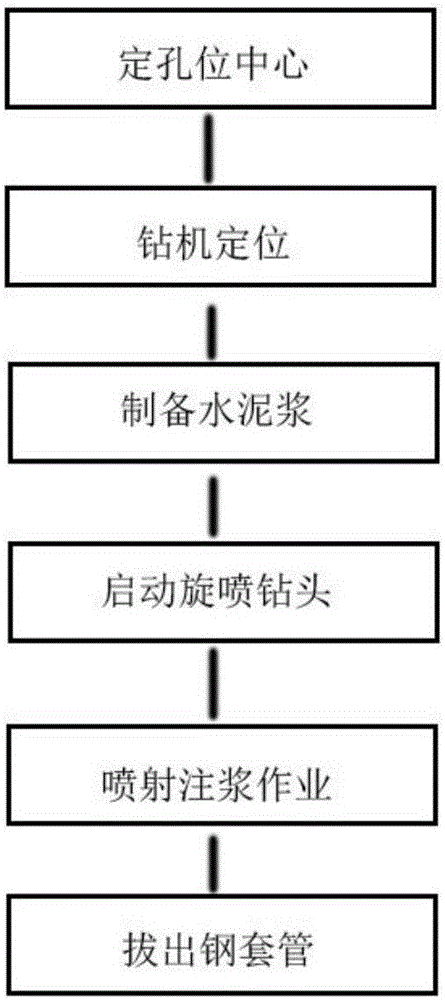

[0016] The construction method of a full casing rotary grouting pile of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0017] As shown in the figure, a construction method of a full casing rotary grouting pile is characterized in that the construction steps are as follows:

[0018] Step 1: Taking the center of the hole as the center of the circle, insert the prefabricated steel casing with a diameter slightly larger than the designed pile body into the ground until it is 500mm below the design elevation;

[0019] The second step: drilling rig positioning. Move the rotary grouting pile machine to the designated pile position (casing center), align the drill bit to the center of the hole position, and level the drilling machine at the same time, place it stably and horizontally, and the verticality deviation of the drill pipe is not more than 1% to 1.5%. After being in place, first conduct a low-pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com