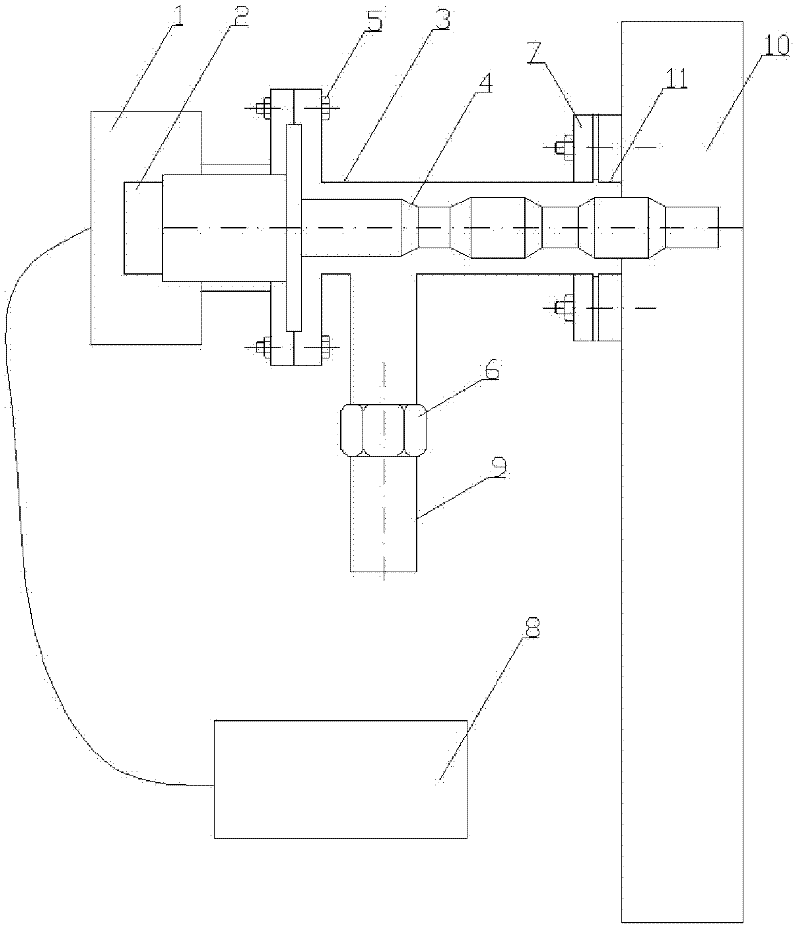

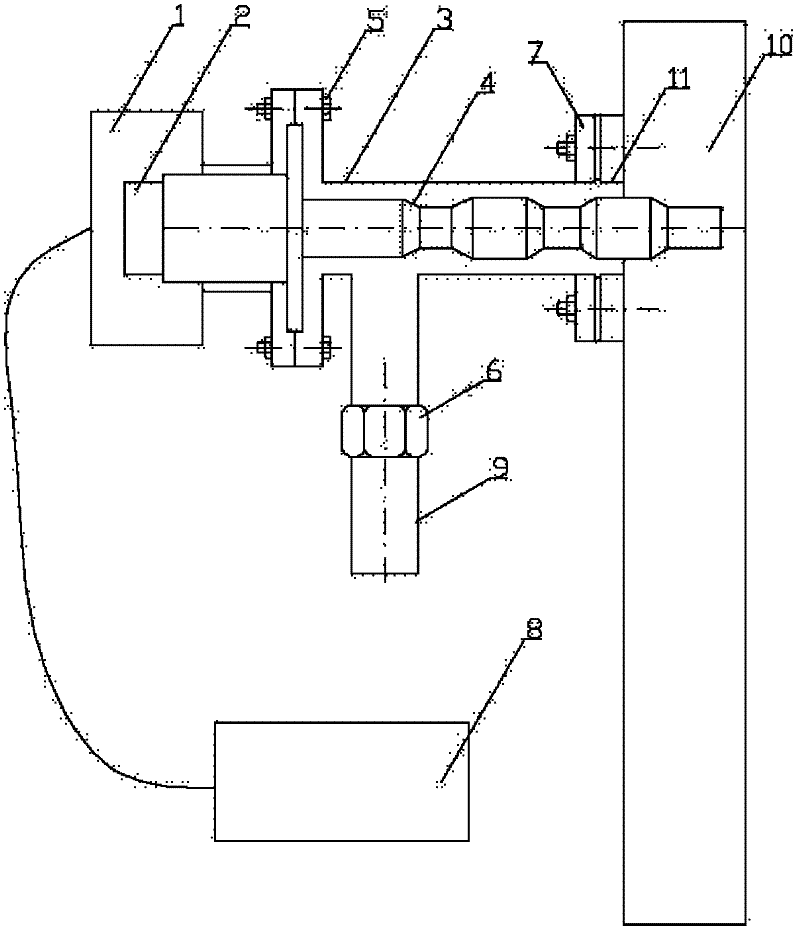

Device and method for restraining and eliminating dirt of recycled water plate heat exchanger on line

A technology of plate heat exchanger and reclaimed water, applied in the direction of cleaning heat transfer devices, vibration cleaning, heat exchange equipment, etc., can solve the problems of large differences in dirt types, poor reference of cleaning experience, etc., to restore plate heat exchange It has the advantages of high flow heat transfer performance, simple and compact structure, and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

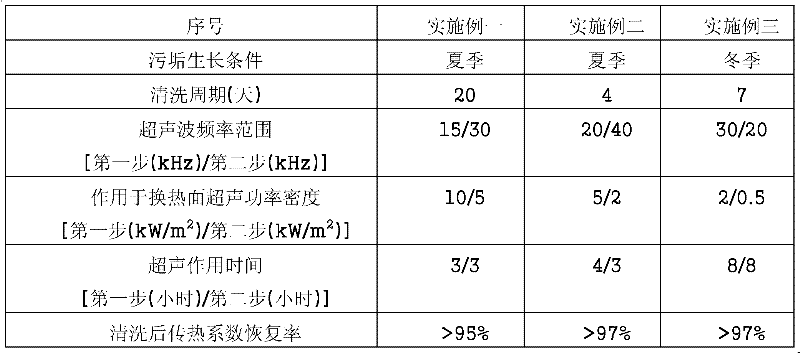

Embodiment 1

[0030] Example 1: Example of on-line cleaning of urban reclaimed water plate heat exchangers with serious fouling in summer cooling conditions

[0031] A water-source heat pump system that uses the secondary effluent of cities and towns as the cold and heat source, and uses plate heat exchangers to recover the low-level heat energy of the secondary effluent of cities and towns. In summer, the heat pump system operated continuously for 20 days, and the cooling efficiency dropped significantly. After analysis, it was found that the secondary effluent was fouled in the plate heat exchanger. The plate heat exchanger is made of stainless steel 316, and the dirt layer on the surface of the plate is relatively thick, with high viscosity and strong adhesion, and the degree of fouling is very serious. The invention adopts the online cleaning of the plate heat exchanger.

[0032] 1. Cleaning method

[0033] Clean as follows:

[0034] ① The regenerated water enters the water treatment...

Embodiment 2

[0039] Example 2: An example of online cleaning of urban recycled water plate heat exchangers under cooling conditions in summer

[0040] A water-source heat pump system that uses the secondary effluent of cities and towns as the cold and heat source, and uses plate heat exchangers to recover the low-level heat energy of the secondary effluent of cities and towns. In summer, the cooling efficiency of the heat pump system dropped rapidly. According to the analysis, it was caused by the fouling of the secondary effluent in the plate heat exchanger. The material of the plate heat exchanger was 304 stainless steel, and the surface of the plate was covered with microbial dirt from bottom to top. Mainly mixed dirt, the degree of fouling is relatively heavy. The invention adopts the online cleaning of the plate heat exchanger.

[0041] 1. Cleaning method

[0042] Clean as follows:

[0043] ① The regenerated water enters the water treatment outer casing through the regenerated wate...

Embodiment 3

[0048] Example 3: An example of on-line cleaning of urban recycled water plate heat exchangers under winter heating conditions

[0049] A water-source heat pump system that uses the secondary effluent of cities and towns as the cold and heat source, and uses plate heat exchangers to recover the low-level heat energy of the secondary effluent of cities and towns. In winter, the heating efficiency of the heat pump system drops, which is caused by scaling of the secondary effluent in the plate heat exchanger after analysis. The plate heat exchanger is made of stainless steel 304, the dirt layer on the high temperature side of the plate surface is thicker, the dirt layer on the low temperature side is thinner, and the degree of fouling is relatively light. The invention adopts the online cleaning of the plate heat exchanger.

[0050] 1. Cleaning method

[0051] Clean as follows:

[0052] ①The regenerated water enters the water treatment outer casing through the regenerated wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com