Flat-type efficient plate and strip instant freezer

A flat-type, quick-freezing machine technology, used in coolers, lighting and heating equipment, cooling fluid circulation devices, etc., can solve the problems of long freezing time, low wind speed, poor quality of frozen materials, etc., to achieve increased heat transfer coefficient, The effect of doubling the heat transfer area and fast freezing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing:

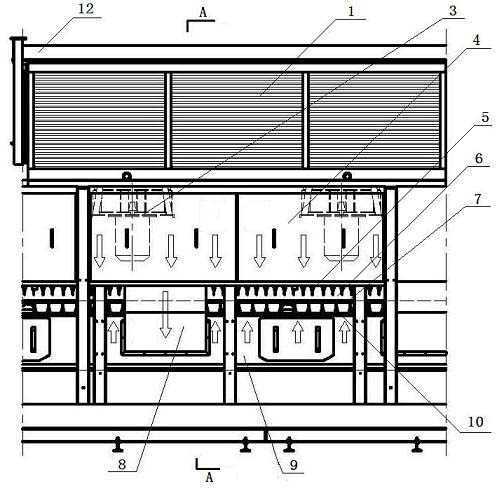

[0014] figure 1 It is the schematic diagram of the present invention, figure 2 for figure 1 A-A sectional view, as shown in the figure, the present invention includes an evaporator (1) and a cold air chamber (2) in the storage body (12), and the evaporator (1) and the cold air chamber (2) are sequentially equipped with The centrifugal fan (3), the upper blowing chamber (4), the upper nozzle (5) and the strip (7), are characterized in that: the upper blowing chamber (4) also passes through the upper and lower blowing chamber air passages (8), The lower blowing chamber (9), the lower nozzle (10), and the return air chamber (11) are connected to the evaporator (1).

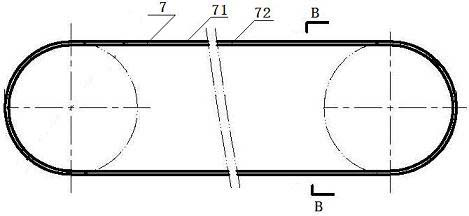

[0015] image 3 For the strip schematic diagram, Figure 4 for image 3 The B-B sectional view of Figure 5 for Figure 4 The enlarged view at C, as shown in the figure, the strip (7) in the present inven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com