Alignment method and system for manufacturing film photovoltaic assembly

A thin-film photovoltaic module, alignment system technology, applied in the direction of final product manufacturing, sustainable manufacturing/processing, electrical components, etc., can solve problems such as poor alignment, machine failure, and a large number of product fragments, and achieve stable production process, Eliminate alignment problems and achieve low-cost results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

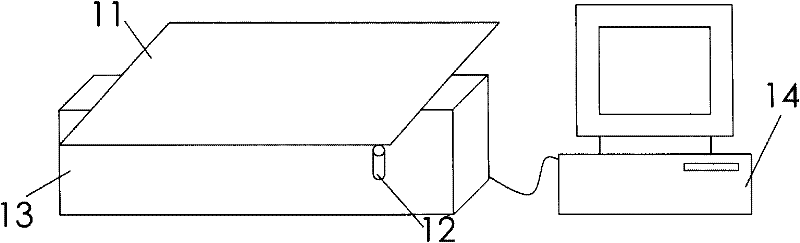

Image

Examples

Embodiment Construction

[0022] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

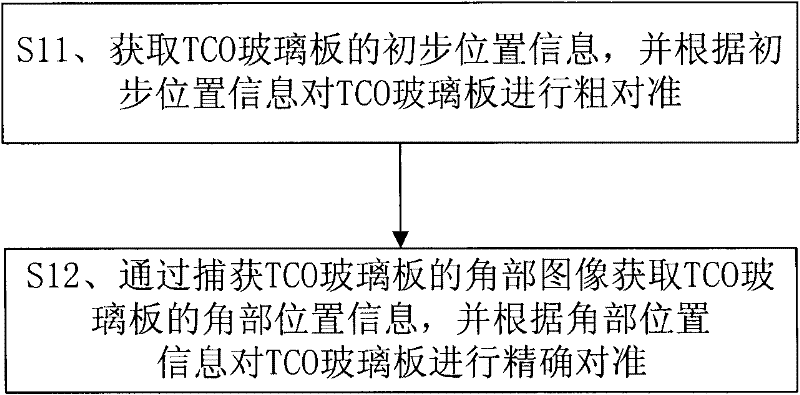

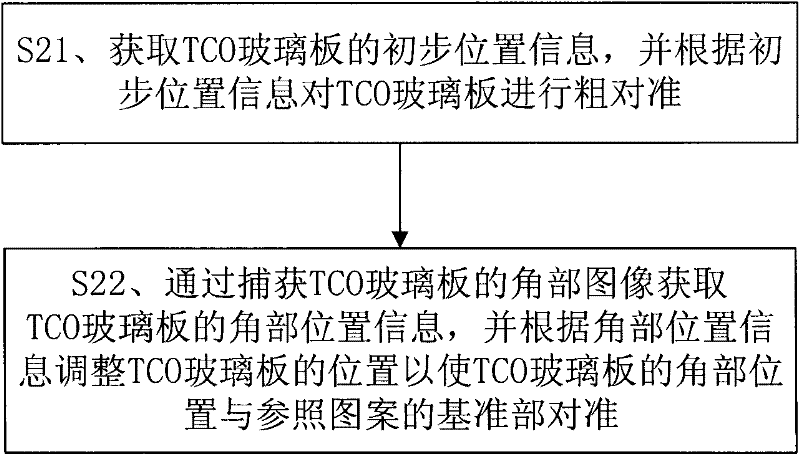

[0023] figure 2 It is a flow chart of an embodiment of the alignment method for thin film photovoltaic module manufacturing of the present invention, the thin film photovoltaic module has a TCO glass plate, and the TCO glass plate is placed on the workbench, as shown in the figure, this implementation The example alignment method includes the following steps:

[0024] S11. Obtain preliminary position information of the TCO glass plate, and roughly align the TCO glass plate according to the preliminary position information;

[0025] S12. Obtain corner position information of the TCO glass plate by capturing the corner image of the TCO glass plate, and precisely align the TCO glass plate according to the corner position information.

[0026] In step S11, after the TCO glass plate is transferred from the thermal control system to the laser chamber, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com