Method for testing the horizontal displacement of CRTS-II type plate ballastless rail bridge abutment of high-speed railway

A slab ballastless track, CRTS-II technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of difficult automatic monitoring, large error of test value, large test error, etc., to avoid bending deformation and large frictional resistance, bridge The horizontal displacement value of the table is accurate and the effect of improving the test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

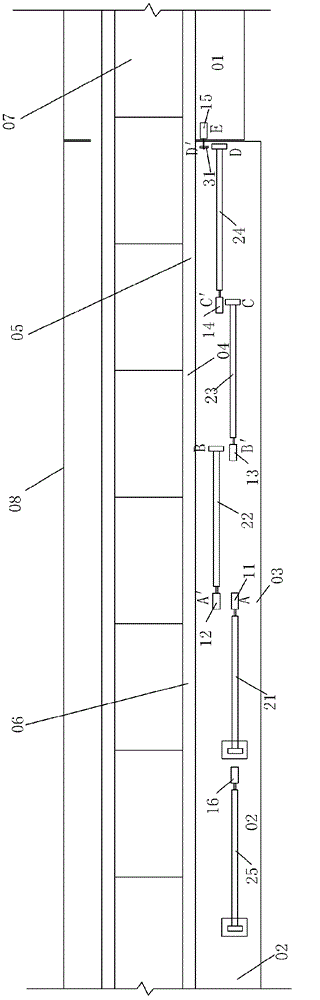

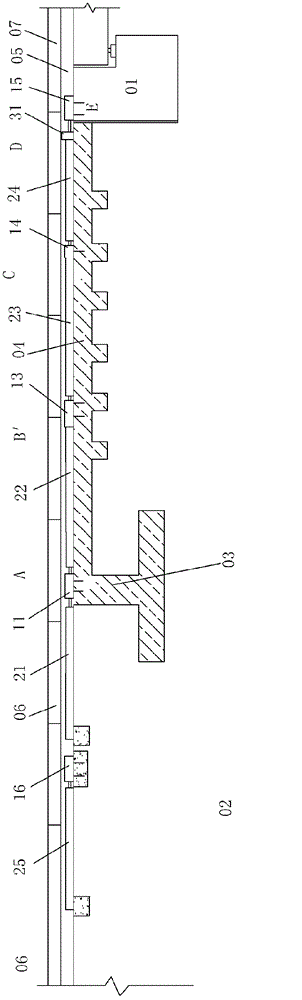

[0035] Figure 1-2 Shown, a kind of embodiment of the present invention is a kind of high-speed railway CRTS-II type slab type ballastless track abutment horizontal displacement testing method, and its steps are:

[0036] a. Test end thorn horizontal displacement

[0037] Fix the displacement sensor-11 on the test point A of the end thorn 03, the telescopic rod of the displacement sensor-11 is connected with the proximal end of the reference rod-21, and the far end of the reference rod-21 is anchored on the roadbed 02, and the displacement sensor-11 11 Obtain the horizontal displacement test value X of end thorn 03 0 ;

[0038] b. Test the horizontal deformation of the friction plate

[0039] Fix the displacement sensor 2 12 on the test point A' of the end thorn 03, the test point A' and the test point A of the end thorn 03 are located on the same cross-section, the telescopic rod of the displacement sensor 2 12 and the distal end of the reference rod 22 connection, the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com