Spark plug and manufacturing method thereof

A manufacturing method and a technology of spark plugs, which are applied in the manufacture of spark plugs, spark plugs, electrical components, etc., can solve the problems of low processing pass rate, reduced strength of spark plugs, and difficult process of wiring screws, etc., to solve the problem of forced growth, shortening the length of rods, The effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Through the research of the present invention, the researchers found that due to the miniaturization of the engine and the stringent emission regulations, technologies such as turbocharging and direct injection in the cylinder have been applied to the engine, which has caused the required spark plug ignition voltage to increase from below 20kv to 40kv Next, with the increase of the ignition demand voltage, there is a phenomenon that the current leaks from the terminal part of the spark plug screw to the case. Therefore, in recent years, spark plugs with a longer distance from the terminal part of the spark plug connection screw to the case have appeared. This structure will inevitably lead to wiring Since the length of the rod-shaped portion of the screw becomes longer, bending tends to occur.

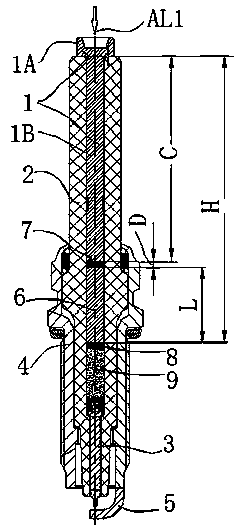

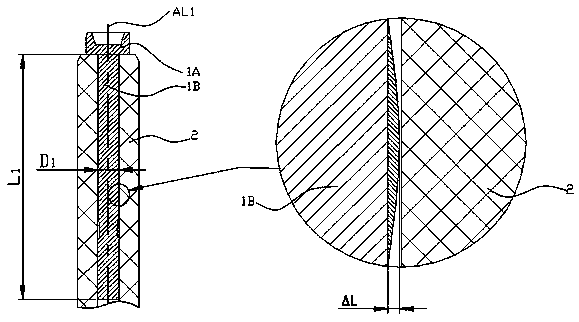

[0035] Therefore, the present invention proposes a spark plug with a cup-type terminal, including an insulator 2, a terminal screw 1, a center electrode 3, a side electrode 5 and...

Embodiment 2

[0065] The basic principle of embodiment two is the same as that of embodiment one, but the materials and structures adopted are different, as attached Figure 4As shown, it is a cup-type terminal spark plug, including an insulator 202, a terminal screw 201, a center electrode 203, a side electrode 205, and a housing 204; wherein, the insulator 202 has a stepped hole along the axial direction; at least a part of the center electrode 203 Inserted at the front end side of the stepped hole; the terminal screw 210 has a terminal portion 201A and a rod-shaped portion 201B, and the rod-shaped portion 201B is inserted into the stepped hole of the insulator, and the terminal portion 201B leaks out from the rear end of the insulator, and the terminal portion 201B has a cup-shaped feature ; In order to increase the creepage distance, the structure of the extended insulator is adopted, that is, the distance between the terminal part 201B of the terminal part 201 of the terminal screw 201 ...

Embodiment 3

[0072] The basic principle of the third embodiment is the same as that of the first embodiment, except that the materials and structures adopted are different, as shown in the attached Figure 5 Shown is a common terminal spark plug, including an insulator 302, a terminal screw 301, a center electrode 303, a side electrode 305, and a housing 304; wherein, the insulator 302 has a stepped hole along the axis; at least a part of the center electrode 303 is inserted into The front end side of the stepped hole; the terminal screw 301 has a terminal portion 301A and a rod-shaped portion 301B, and the rod-shaped portion 301B is inserted into the stepped hole of the insulator 302, the terminal portion 301A leaks out from the rear end of the insulator 302, and the terminal portion 301A is a common cylindrical terminal , the height of the terminal part 301A is within 5mm; in order to increase the creepage distance, a growth type insulator structure is adopted, that is, the distance betwe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com