New method for plugging dewatering well in basement

A technology for dewatering wells and basements, which is applied in protection devices, buildings, infrastructure engineering, etc., can solve problems such as dewatering well blockage, and achieve the effect of ensuring no water leakage and quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

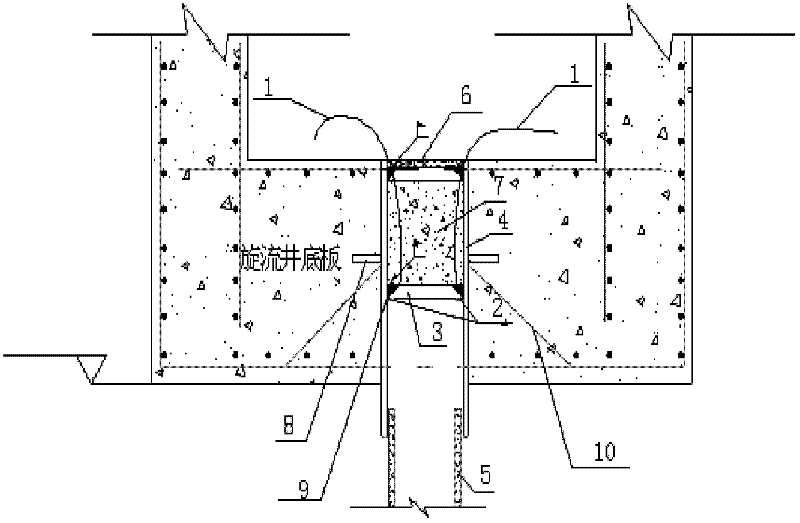

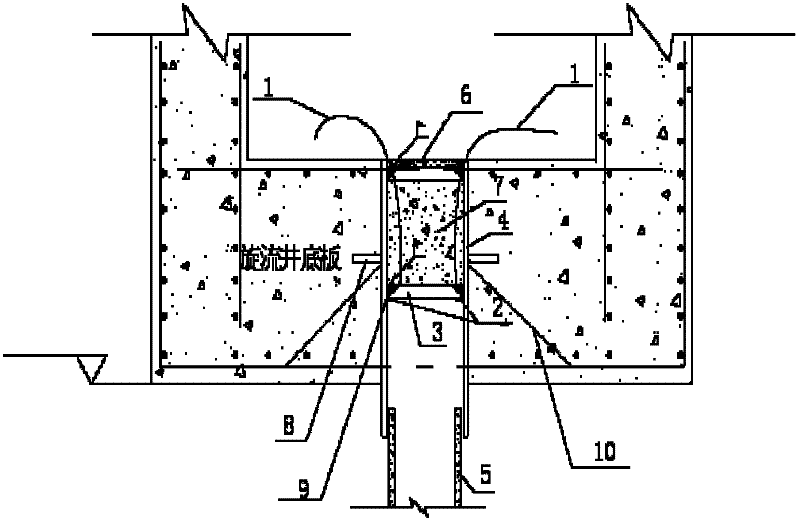

[0022] In order to further understand the present invention, the present invention will be further described below in conjunction with accompanying drawing:

[0023] See attached figure 1 , a method for plugging a dewatering well in a basement of the present invention. When implementing the present invention, a steel bar fixing frame 10 must be provided first. After the support is provided, at first the sand-free concrete pipe 5 is inserted underground to a depth of 30m. The outer diameter of the concrete pipe 5 is Φ500mm, and then the steel pipe 4 is put on the sandless concrete pipe 5. The length of the steel pipe is 2.5m and the diameter is Φ600×8; after the steel pipe 4 is set, the dewatering pump can be placed in the steel pipe 4 Drain water; then set a water stop ring 8 at the outer middle part of the above-mentioned steel pipe 4, and the specification of the water stop ring 8 is made of a steel plate with a diameter of Φ1000×4; At less than 800 mm, weld short steel bar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com