Method of manufacturing board with leather by-products and board manufactured by adopting the method

A by-product and leather technology, which is applied in the field of natural leather by-product manufacturing boards, can solve problems such as poor product performance, low fiber binding force, and environmental pollution, so as to improve resource recycling, high added value, and prevent environmental pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

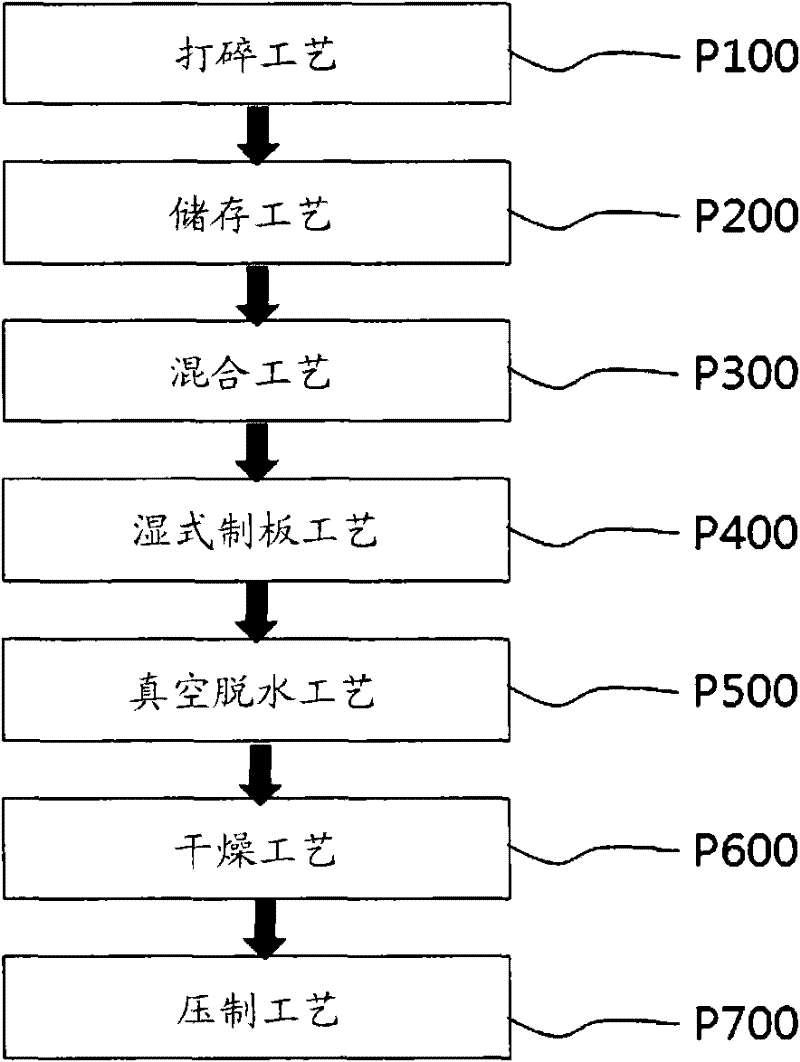

Method used

Image

Examples

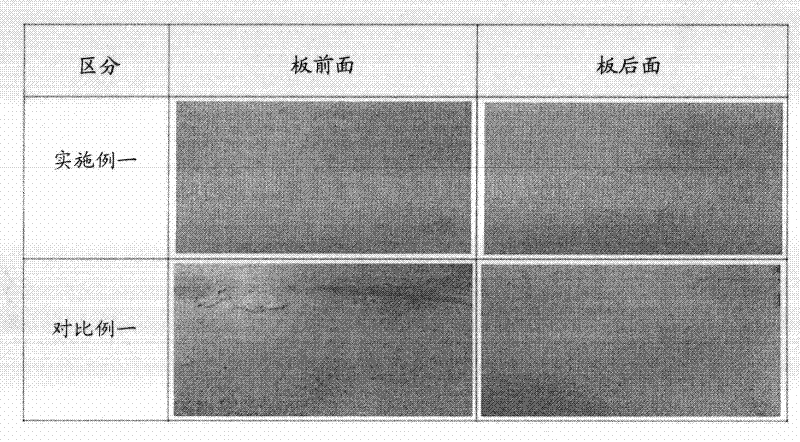

Embodiment 1

[0046] The cutting waste was subjected to beating treatment for 20 minutes to shorten the cutting waste. Then, after the short-fiberized trimmed waste was moved to the storage process, based on 100 parts by weight of water, 1 part by weight of S-205 as a water-soluble SB latex (Styrene Butadienelatex) with a high glass transition temperature (Tg) was added, Mix and stir for 10 minutes. And, in order to form into a board, dehydration based on hydraulic pressure is performed in a wet board making process so that the water content is less than 60%. Then, a vacuum dehydration process as a vacuum-based secondary dehydration process is performed again so that the water content is less than 30%. Then, it is dried in a dry chamber so that the water content becomes 10% or less. Then, at a temperature of 120°C and 150kgf / cm 2 The board is produced by pressing and compressing under high pressure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com