Structure and method for packaging blue-green laser chip based on thin crystal

A chip packaging structure, blue-green laser technology, applied in the laser field, can solve problems such as difficult operation, difficult actual production, and difficulty in deepening photoresist

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

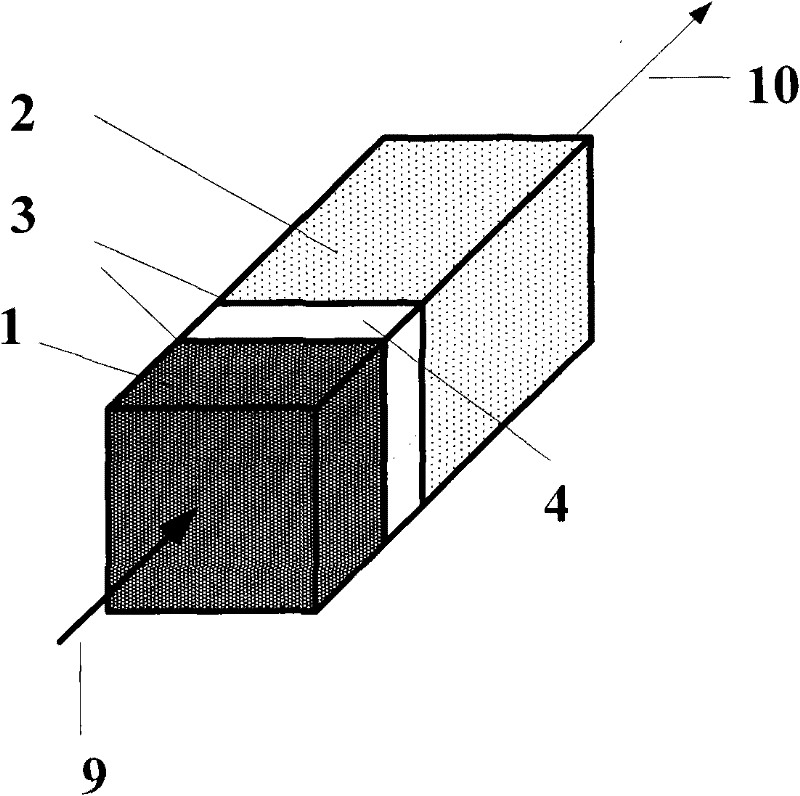

Embodiment 1

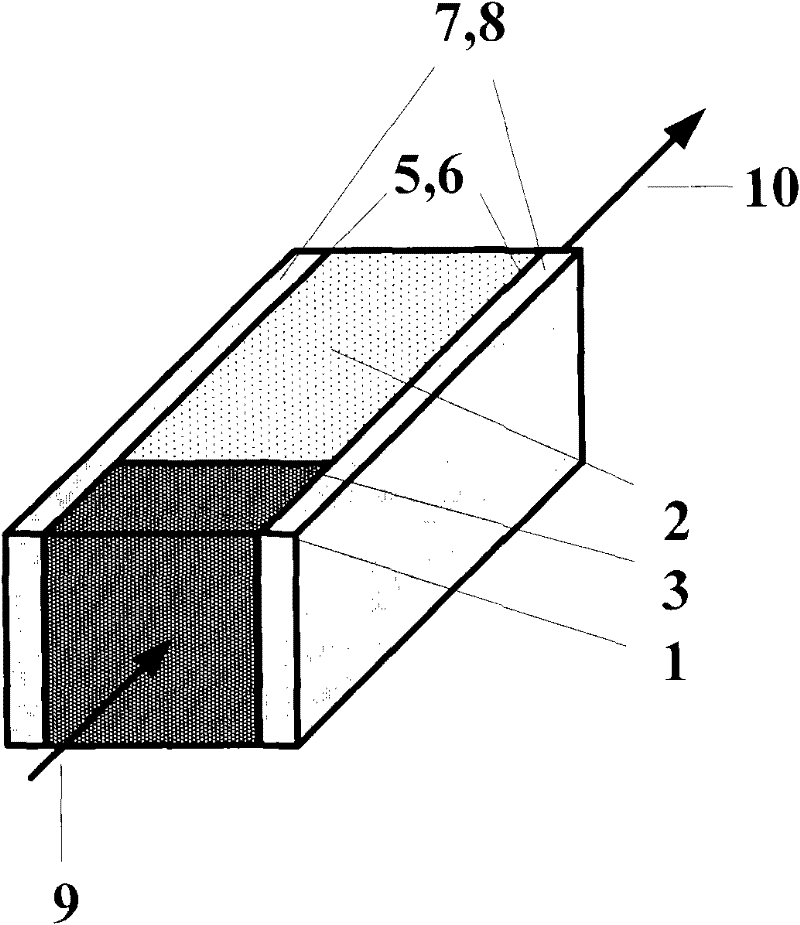

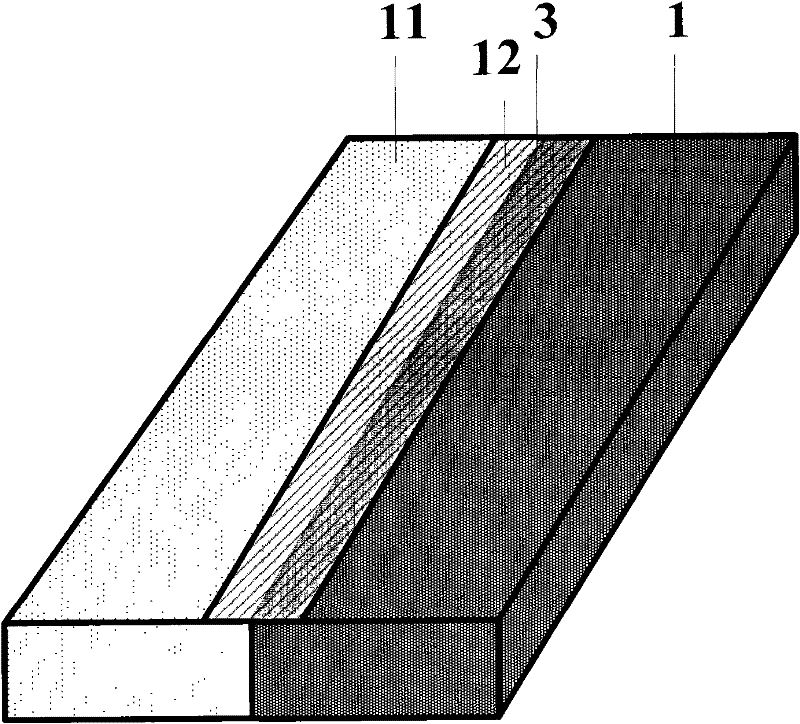

[0016] Embodiment one: structure such as Figure 2a , as shown in the figure b, the light-transmitting surface 3 of the thin neodymium-doped laser crystal 1 and the thin nonlinear frequency conversion crystal 11 is polished and cleaned, and then bonded by optical or optical glue. Then, use epoxy resin 12 to seal any side around the joint of the light-transmitting surface of the chip, a very small part of the epoxy-based resin penetrates into the joint of the light-transmitting surface, and put the structure into an oven to heat to cure the glue.

Embodiment 2

[0017] Embodiment two: structure such as Figure 3a , as shown in the figure b, the light-transmitting surface 3 of the thin neodymium-doped laser crystal 1 and the thin nonlinear frequency conversion crystal 11 is polished and cleaned, and then bonded by optical or optical glue. Then, use epoxy resin 12 to seal any two sides around the junction of the light-transmitting surface of the chip, a very small part of the epoxy-based resin penetrates into the junction of the light-transmitting surface, and put the structure into an oven to heat to cure the glue.

Embodiment 3

[0018] Embodiment three: structure such as Figure 4a , as shown in the figure b, the light-transmitting surface 3 of the thin neodymium-doped laser crystal 1 and the thin nonlinear frequency conversion crystal 11 is polished and cleaned, and then bonded by optical or optical glue. Then, use epoxy resin 12 to seal any three sides around the joint of the light-transmitting surface of the chip, a very small part of the epoxy-based resin penetrates into the joint of the light-transmitting surface, and put the structure into an oven to heat to cure the glue.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com