Iodine value absorbance measurement method for judging quality of aged tobacco leaves

A technology of absorbance and tobacco leaves, which is applied to the measurement of color/spectral characteristics, etc., can solve the problems of large human factors in the measured value and difficulty in judging the titration end point, etc., and achieve the effect of accurate and reliable measurement data, strong repeatability and good correspondence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

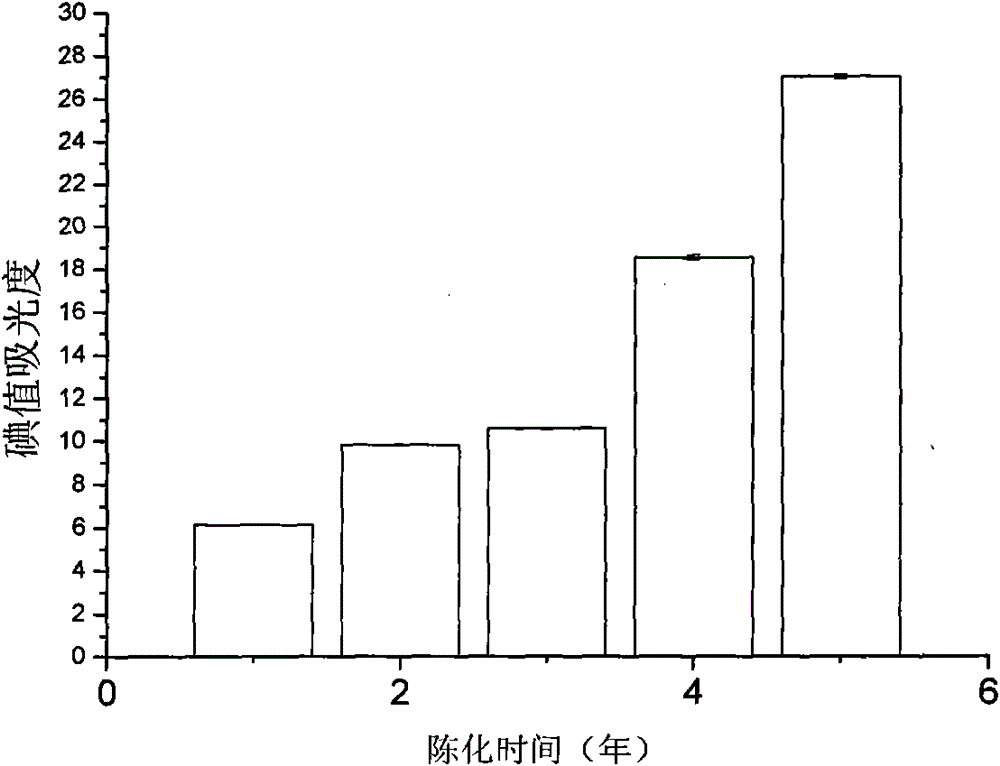

[0032] Example 1: Quality of flue-cured tobacco leaves of five aging times in Qujing, Yunnan

[0033] The tobacco leaves are five-year flue-cured tobacco from 2004 to 2008 in the Qujing area of Yunnan Province, with an aging time of 5 to 1 year, and the grades of the tobacco leaves are all middle tobacco CLF. It was measured by the following method.

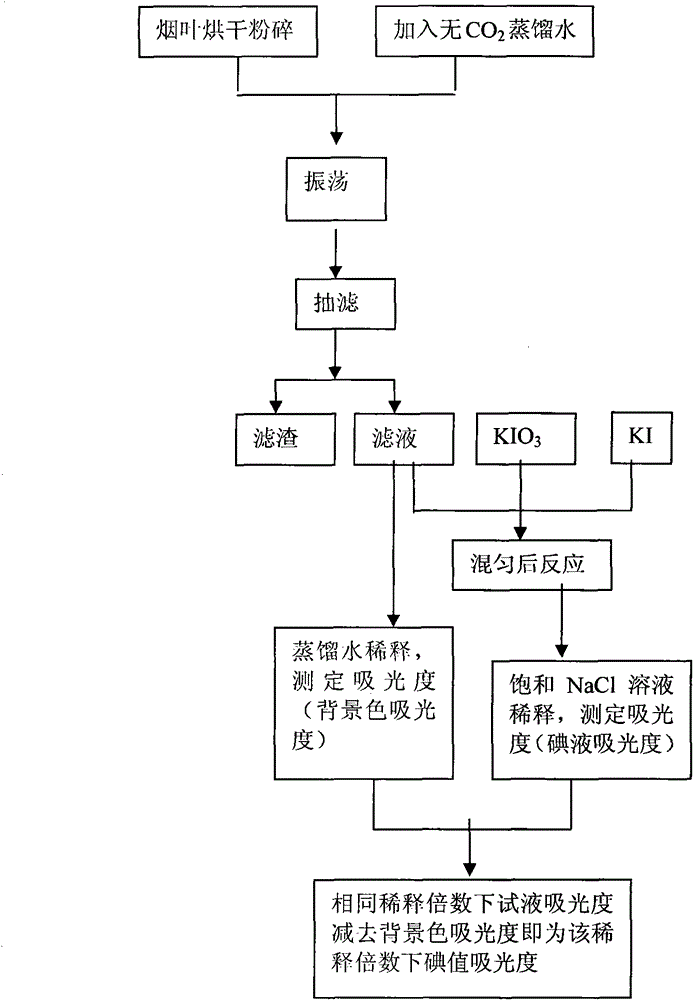

[0034] (1) Preparation of water filtrate of aged tobacco leaves: dry and pulverize the tobacco leaves and sieve 60 mesh, boil in distilled water for 20min to obtain CO2-free 2 For distilled water, take 1 g of pulverized tobacco powder, and add 10 g of CO2-free distilled water according to the ratio of tobacco leaf: water weight ratio of 1:10. Oscillate evenly for 20 minutes under the conditions of an oscillation speed of 120 rpm and an oscillation temperature of 25° C., and obtain the water filtrate of aged tobacco leaves by suction filtration.

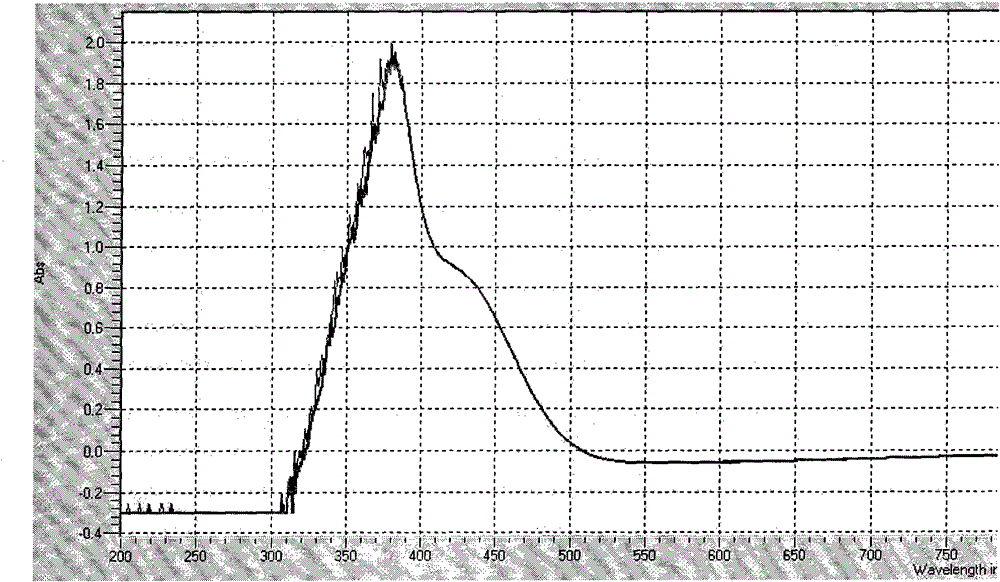

[0035] (2) Pre-measurement treatment: Take 1ml of the water filtrate of aged tob...

Embodiment 2

[0042] Example 2: Quality of Flue-cured Tobacco Leaf at Three Aging Times in Enshi, Hubei

[0043] The tobacco leaves are flue-cured tobacco of three years in Enshi, Hubei Province in 2006, 2007, and 2008. The aging time is three years, two years, and one year respectively. The tobacco leaves are all central tobacco, and the grades are all C2F. It was measured by the following method.

[0044] (1) Preparation of the water filtrate of aged tobacco leaves: dry the tobacco leaves, crush them, and sieve them to 90 meshes, boil them in distilled water for 40 minutes to obtain CO2-free 2 For distilled water, take 5 g of pulverized tobacco powder, and add 250 g of CO2-free distilled water according to the ratio of tobacco leaves: water weight ratio of 1:50. Shake evenly for 30 minutes, the shaking conditions are shaking speed of 180 rpm, shaking temperature of 30°C, and suction filtration to obtain the water filtrate of aged tobacco leaves.

[0045] (2) Pre-measurement treatment: G...

Embodiment 3

[0052] Example 3: Burley Tobacco Leaf Quality of Three Aging Times in the United States

[0053] The tobacco leaves are flue-cured tobacco from the United States in 2003, 2005, and 2006. The aging time is six years, four years, and three years respectively. The tobacco leaves are all central tobacco, and the grade is SC3F. It was measured by the following method.

[0054] (1) Preparation of aged tobacco water filtrate: dry aged tobacco leaves, pulverize, sieve 100 mesh, boil in distilled water for 60min to obtain CO2-free 2 Distilled water, take 6g of pulverized tobacco powder, and add 480g of CO2-free distilled water according to the ratio of tobacco leaves: water weight ratio of 1:80. Oscillate evenly for 50 minutes under the conditions of an oscillating speed of 200 rpm and an oscillating temperature of 37° C., and obtain the water filtrate of aged tobacco leaves by suction filtration.

[0055] (2) Pre-measurement treatment: Get 5ml of the water filtrate of aged tobacco l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com