Cooling water type stepless control condensed heat recovery system

A stepless adjustment, cooling water type technology, applied in the direction of heat recovery system, air conditioning system, ventilation and heating energy recovery system, etc., can solve the problem of large reheating temperature rise, unguaranteed temperature accuracy and safety of refrigeration system In order to reduce the complexity and achieve the effect of indoor temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

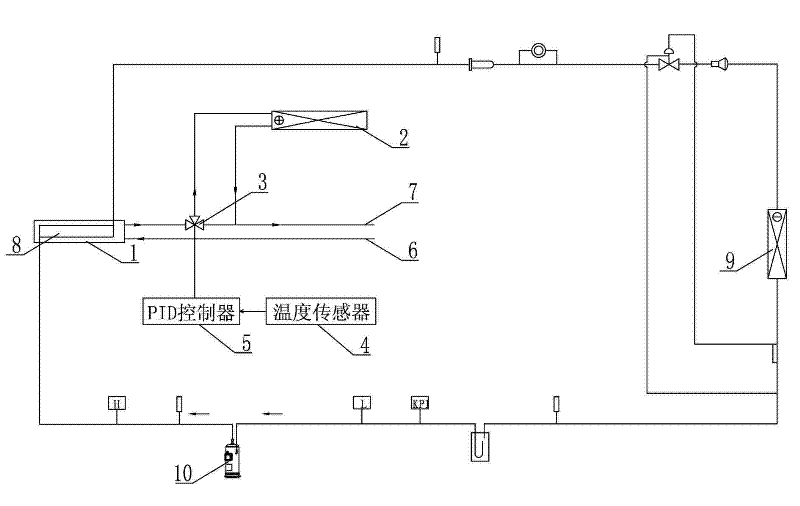

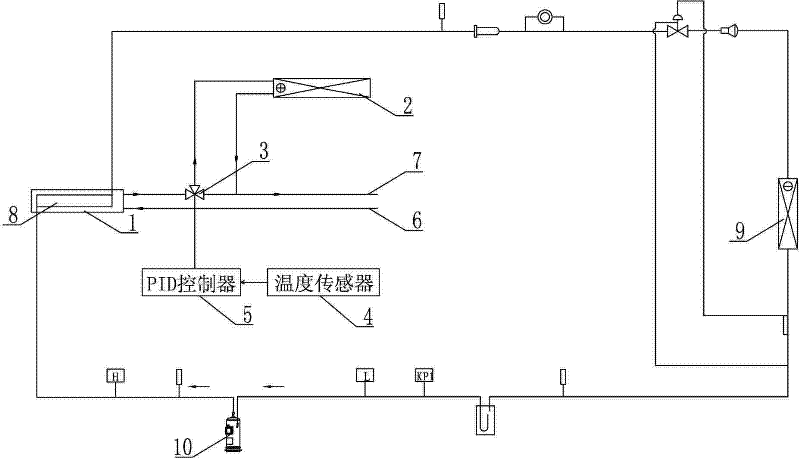

[0020] Such as figure 1 As shown, the cooling water type stepless adjustment condensation heat recovery system of the present invention is installed on the existing constant temperature air-conditioning unit, the air-conditioning unit mainly includes a condenser 8, an evaporator 9, a compressor 10, etc., and the air-conditioning unit is an existing There are technologies, so I won't describe them in detail.

[0021] The cooling water type stepless adjustment condensation heat recovery system of the present invention includes:

[0022] Condenser water-cooled heat exchanger 1 is connected with water supply pipe 6 and return water pipe 7. Condenser water-cooled heat exchanger 1 is connected to condenser 8 and exchanges heat with condenser 8 to recover the air conditioner condenser generated heat.

[0023] The reheat heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com