Sapphire inner-spiral pulse type spiral-complex comprehensive-drilling bit with mud diversion trench

A technology of inner helix and diversion groove, which is applied in the field of sapphire inner helix pulsed helical composite comprehensive drilling bit, to achieve the effect of small lifting resistance, improved drilling speed and long-lasting wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

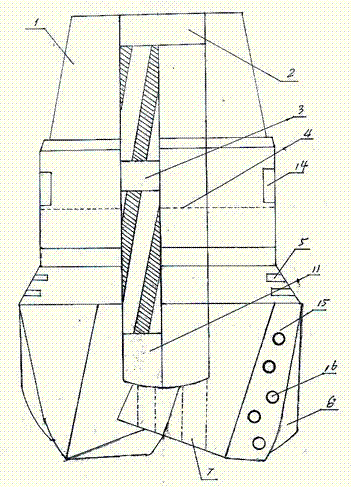

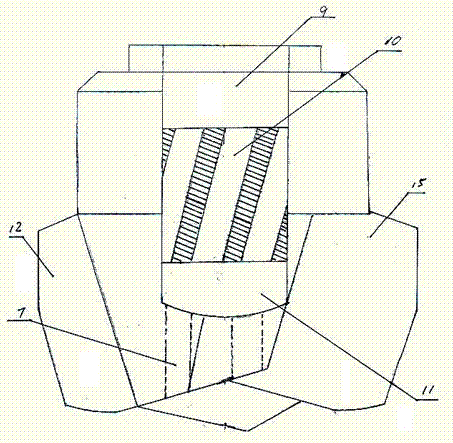

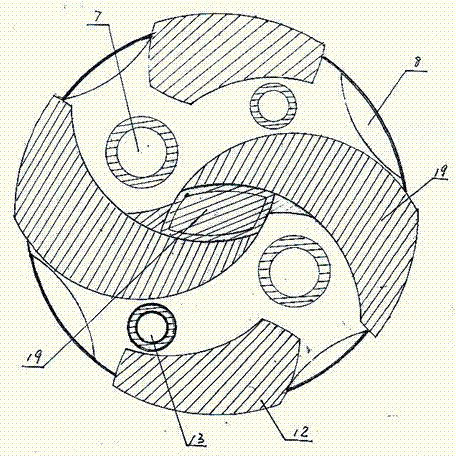

[0025] Accompanying drawing is embodiment of the present invention.

[0026] Below in conjunction with appended content of the invention is described further:

[0027] refer to Figure 1 to Figure 6 As shown, one end of a threaded connector 1 of a sapphire inner spiral mud diversion groove pulsed helical complex is fully drilled into the drill bit is connected to the drill pipe, and the other end is connected to the drill bit helicoid 15 through the butt welding seam 4, the threaded thread The connector 1 is provided with a tool groove 14, the upper end of the drill threaded connector 1 is excavated with a first-level pulse cavity 2, and the lower end is excavated with a second-level pulse cavity 3, and the center of the drill bit helix 15 is respectively excavated with a second A buffer cavity 9, a second buffer cavity 11, an inner spiral diversion groove 10, a plurality of spiral wing bodies 12, an outer spiral wing 6, an outer spiral diversion groove 8, and welded gauge te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com