High cohesiveness CA mortar

A mortar and polypropylene fiber technology, applied in the field of high cohesive CA mortar, can solve the problems of CA mortar self-leveling ability decline, large dosage, uneven effect, etc., to improve crack resistance and volume stability, improve Anti-settling ability, the effect of preventing the sinking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

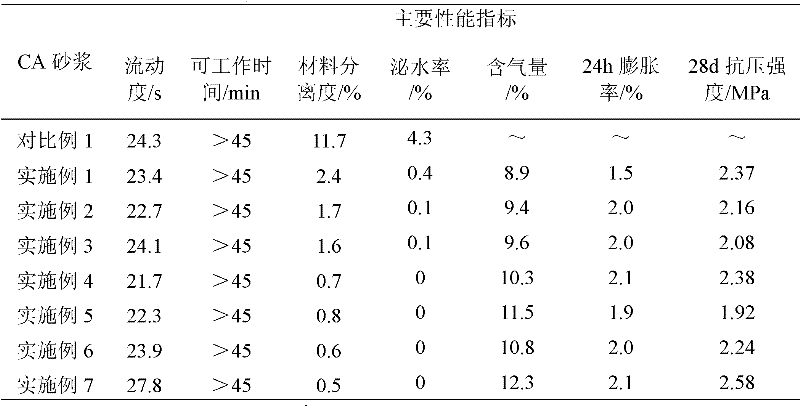

Examples

Embodiment 1

[0025] The preparation of embodiment 1, CA mortar

[0026] (1) Preparation of dry powder: mix PI 42.5 cement, expansion agent, river sand (fineness modulus of 1.4) and aluminum powder (200 mesh) and stir evenly to obtain dry powder; among them, PI 42.5 cement, UEA expansion agent , The mass-number ratio of river sand and aluminum powder is 90:10:200:0.015;

[0027] (2) Preparation of CA mortar: Mix slow-cracking cationic emulsified asphalt, water, polycarboxylate superplasticizer, polyurethane thickener (dissolved well in water) and rosin thermal polymer air-entraining agent (dissolved well in water). Stir evenly to obtain a liquid mixture, put the liquid mixture into the dry powder obtained in the previous step and stir evenly, then add a silicone defoamer for defoaming to obtain CA mortar; among them, PI 42.5 cement, expansion agent, river sand, The mass-number ratio of the emulsified asphalt, water, water reducer, air-entraining agent, defoamer, aluminum powder and thicken...

Embodiment 2

[0029] Embodiment 2, the preparation of CA mortar

[0030] (1) Preparation of dry powder: mix PI 52.5 cement, expansion agent, river sand (fineness modulus 1.8) and aluminum powder (250 mesh) and stir evenly to obtain dry powder; among them, PI 52.5 cement, UEA expansion agent , The mass-number ratio of river sand and aluminum powder is 90:10:200:0.015;

[0031] (2) Preparation of CA mortar: Mix slow-cracking cationic emulsified asphalt, water, polycarboxylate superplasticizer, polyurethane thickener (dissolved well in water) and rosin thermal polymer air-entraining agent (dissolved well in water). Stir evenly to obtain a liquid mixture, put the liquid mixture into the dry powder obtained in the previous step and stir evenly, then add a silicone defoamer for defoaming to obtain CA mortar; among them, PI 52.5 cement, expansion agent, river sand, The mass-number ratio of emulsified asphalt, water, water reducer, air-entraining agent, defoamer, aluminum powder and thickener is 9...

Embodiment 3

[0033] Embodiment 3, the preparation of CA mortar

[0034] (1) Preparation of dry powder: mix PII 42.5 cement, expansion agent, river sand (fineness modulus 1.5) and aluminum powder (250 mesh) and stir evenly to obtain dry powder; among them, PII 42.5 cement, UEA expansion agent , The mass-number ratio of river sand and aluminum powder is 90:10:200:0.015;

[0035] (2) Preparation of CA mortar: Mix slow-cracking cationic emulsified asphalt, water, polycarboxylate superplasticizer, polyurethane thickener (dissolved well in water) and rosin thermal polymer air-entraining agent (dissolved well in water). Stir evenly to obtain a liquid mixture, put the liquid mixture into the dry powder obtained in the previous step and stir evenly, then add a silicone defoamer for defoaming to obtain CA mortar; among them, PII 42.5 cement, expansion agent, river sand, The mass-number ratio of emulsified asphalt, water, water reducer, air-entraining agent, defoamer, aluminum powder and thickener is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com