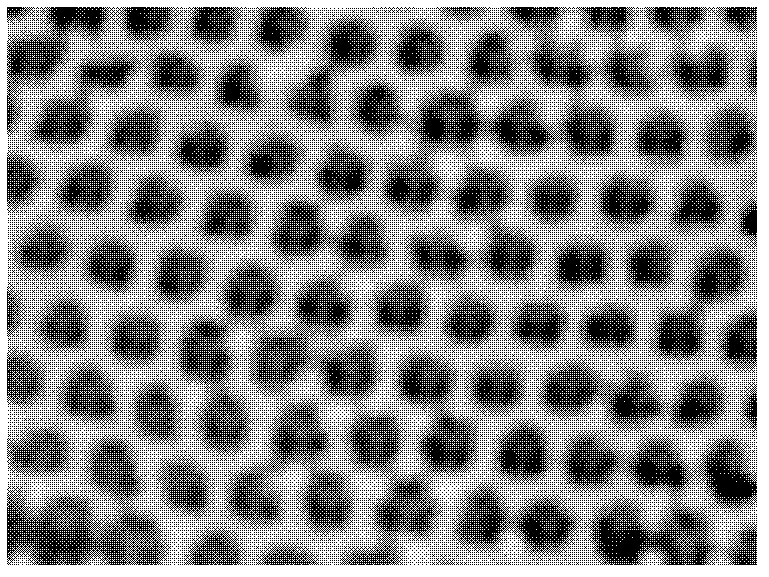

Preparation method of ordered macroporous materials with titanium dioxide inverse opal structures

An inverse opal structure, titanium dioxide technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of low degree of order, complex preparation process, and many impurities in materials, and achieve high degree of order, good uniformity, The effect of less impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0034] Method operation steps of the present invention are as follows:

[0035] Step 1): Using soap-free emulsion polymerization method, polystyrene monomer is used as raw material to prepare PS microspheres;

[0036] The specific steps are: A) Take 100ml of deionized water and add it to a 250ml four-necked flask, and pass nitrogen gas (N 2 ) for 30min to remove the air in the bottle. Then put it into a constant temperature tank, slowly heat up to 60°C, and keep it at a constant temperature for 10 minutes; B) Add 6ml of styrene to the flask under constant temperature in step A); then raise the temperature to 70°C, keep at a constant temperature for 5 minutes, C) to a constant temperature of 70 10ml of an aqueous solution containing 0.2g of potassium peroxodisulfate used as an initiator and MAA as a surface modifier ( Methacrylic acid) 1.2g, after fully reacting for 24 hours under nitrogen protection, the original dispersion of PS microspheres was obtained; D) Put the origin...

example 2

[0044] The operation of this example is basically the same as that of Example 1, the difference lies in:

[0045] In step 1), add 12ml of styrene to the flask under constant temperature in step A); D) The centrifugal washing time in step is 20min; after taking it out, put it into an ultrasonic cleaner for ultrasonic cleaning for 30min; E) Repeat step D ) 3 times to obtain the PS microspheres; take 12ml of PS microspheres and disperse them in a 30% ethanol solution to prepare a PS microsphere dispersion for use;

[0046] The substrate used in step 2) is a mica sheet, and the hydrophilic treatment step F) of the mica sheet is the same as in Example 1; when the PS microspheres are assembled by the vertical deposition method, the volume concentration of the PS microspheres in the beaker in step G) is 0.08% ; Step H) The constant temperature in the vacuum drying oven is 70°C and the humidity is 90%; after the hydrophilic treated mica sheet is vertically deposited in the PS microsph...

example 3

[0050] The operation of this example is basically the same as that of Example 1, the difference lies in:

[0051] In step 1), add 5ml of styrene to the flask under the constant temperature state in step A); D) the centrifugal washing time in step is 20min; after taking it out, put it into the ultrasonic cleaner for ultrasonic cleaning for 30min; E) repeat the steps D) 2 times to obtain the PS microspheres; take 8ml of PS microspheres and disperse them in an ethanol solution with a concentration of 30% to prepare a PS microsphere dispersion for use;

[0052] The substrate used in step 2) is a monocrystalline silicon wafer, and the hydrophilic treatment step F) of the monocrystalline silicon wafer is the same as in Example 1; when the PS microspheres are assembled by the vertical deposition method, the volume of the PS microspheres in the beaker in step G) The concentration is 0.10%; Step H) The constant temperature in the vacuum drying oven is 65°C and the humidity is 93%; afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com