Method for maintaining AQFN (Advanced Quad Flat No-Lead Package) mobile phone motherboard and maintenance table

A repair station and motherboard technology, applied in the field of repair stations, can solve the problems of long maintenance heating time, high cost, and large footprint of the repair station, and overcome the problems of low maintenance efficiency, high repair yield, and small footprint Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0062] Specific embodiment one, a method for repairing the motherboard of an AQFN mobile phone.

[0063] The maintenance method described in this embodiment uses the maintenance station described in the second embodiment, and the specific steps are as follows:

[0064] The first step is to adjust the main board fixing table 4, the upper air gun fixing table 5, and the lower air gun fixing table 3 on the maintenance station to the appropriate positions and lock them, and then fix the main board to be repaired, the upper air gun, and the lower air gun respectively on on the respective fixed platforms, so that the upper and lower air guns are respectively aimed at the upper and lower sides of the motherboard to be repaired at the position of the AQFN chip;

[0065] The second step is to set the upper wind gun and the lower wind gun to the appropriate temperature and wind speed level respectively;

[0066] The third step is to turn on the upper and lower air guns at the same time...

specific Embodiment 2

[0075] Specific embodiment two, a maintenance station used in the method for maintaining the motherboard of an AQFN mobile phone.

Embodiment 1

[0076] The maintenance method described in Embodiment 1 requires a dedicated maintenance station.

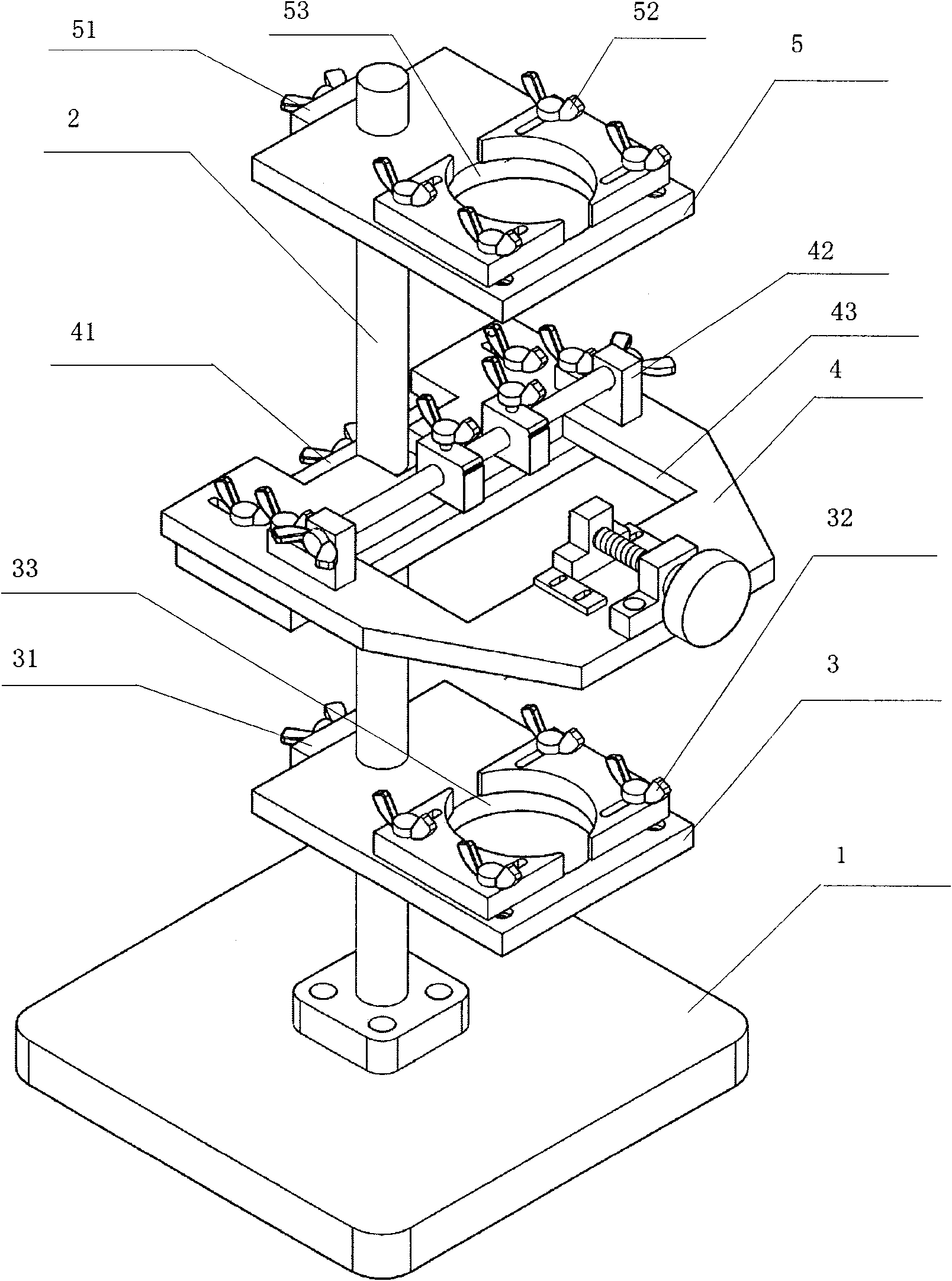

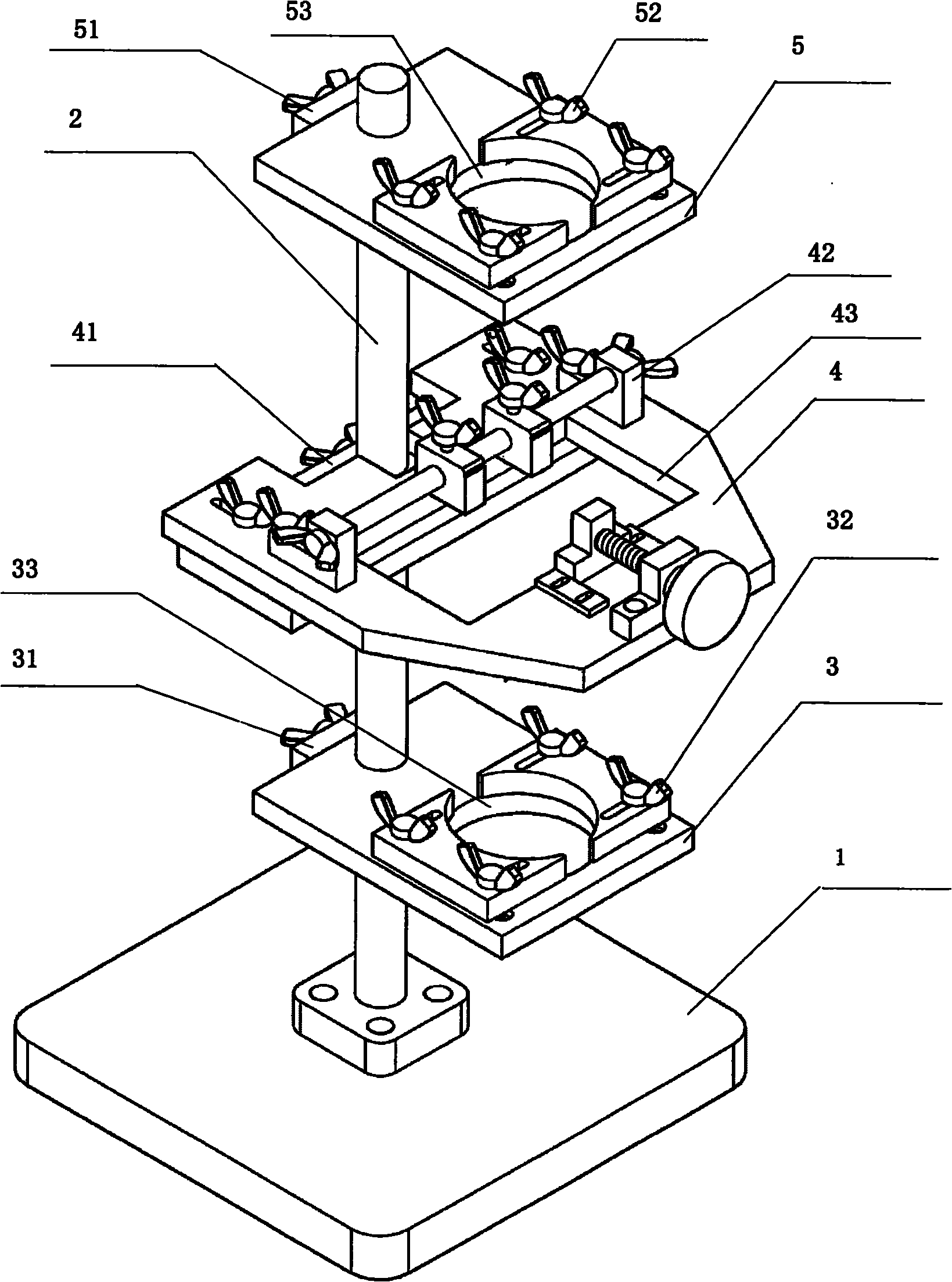

[0077] The maintenance platform is mainly a mechanical positioning device, including a base 1, a platform column 2, a lower air gun fixing platform 3, a main board fixing platform 4, and an upper air gun fixing platform 5; the platform column 2 is fixed on the middle position of the base 1; The lower air gun fixing platform 3, the main board fixing platform 4, and the upper air gun fixing platform 5 are respectively set on the column 2, and each fixing platform is respectively provided with adjustment and locking structures 31, 41, 51 relative to the column 2. These adjustment and locking fixing structures enable the corresponding fixed platform to adjust the axial height along the platform column and adjust the radial angle around the platform column 2 according to the needs of the maintenance position.

[0078] At the same time, the lower and upper air gun fixing platforms 3 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com