Method for preparing anode of solid oxide fuel cell by using immersion method

A solid oxide and fuel cell technology, applied to battery electrodes, circuits, electrical components, etc., can solve the problems of low anode stability, easy aging, and easy performance degradation, etc., and achieve simple preparation process, not easy to fall off, and improve stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

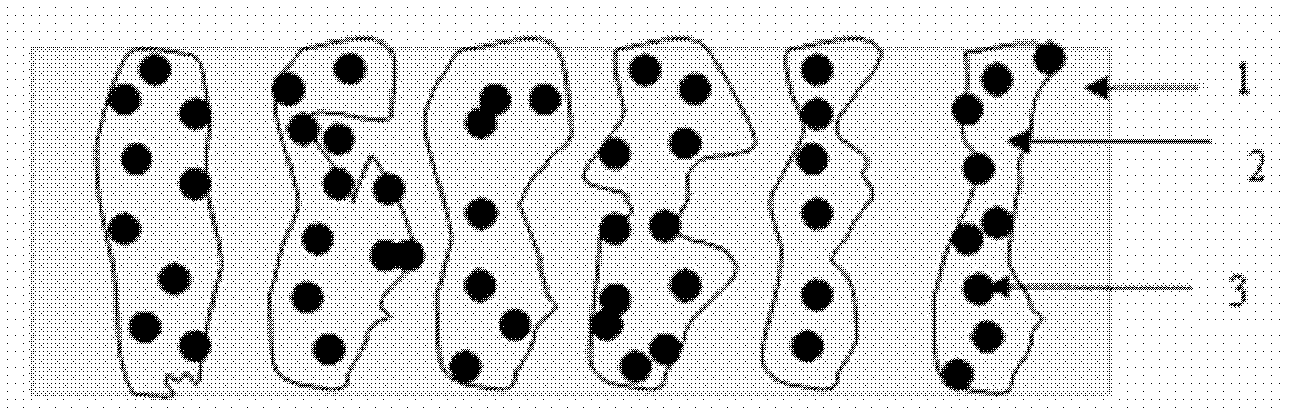

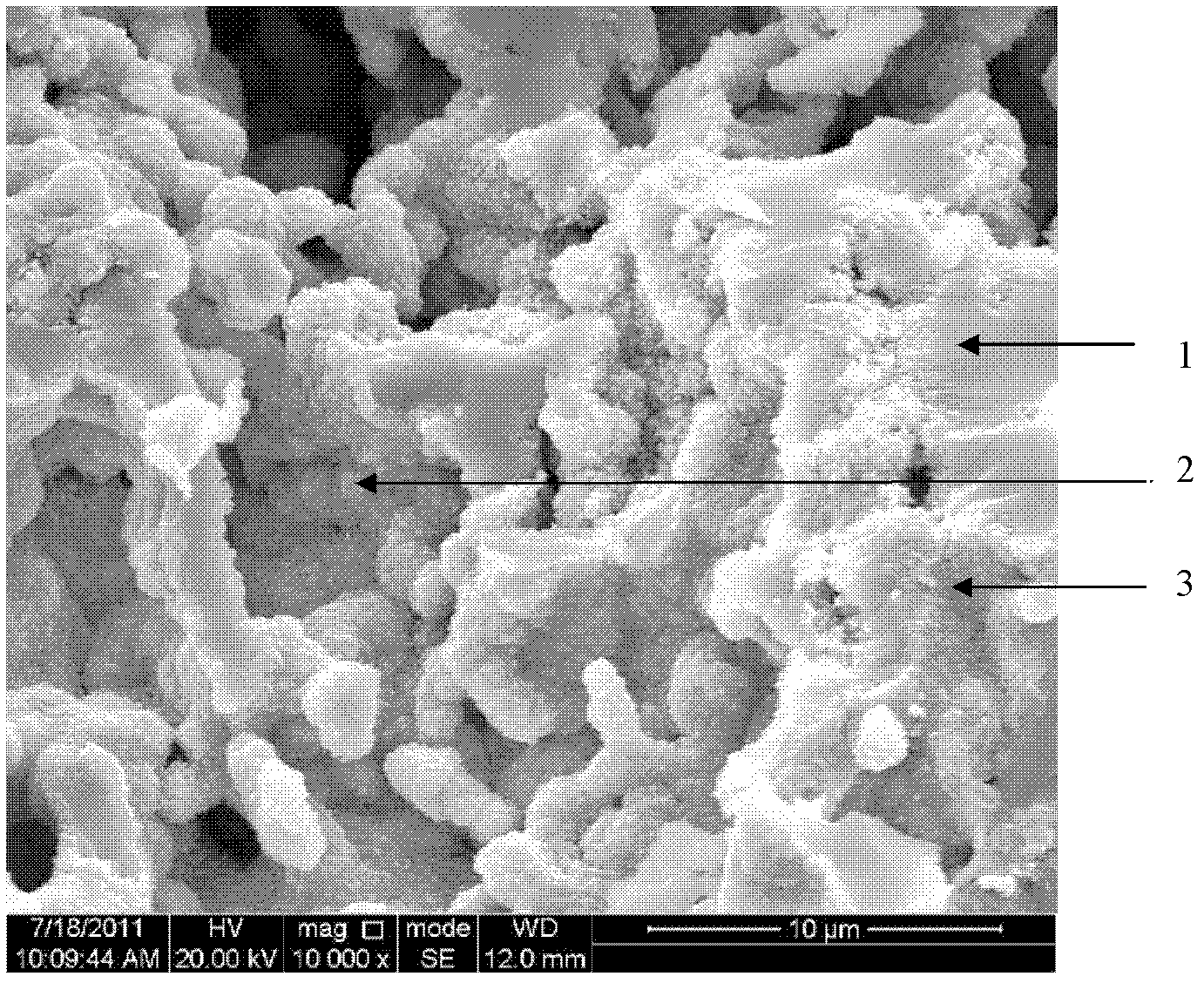

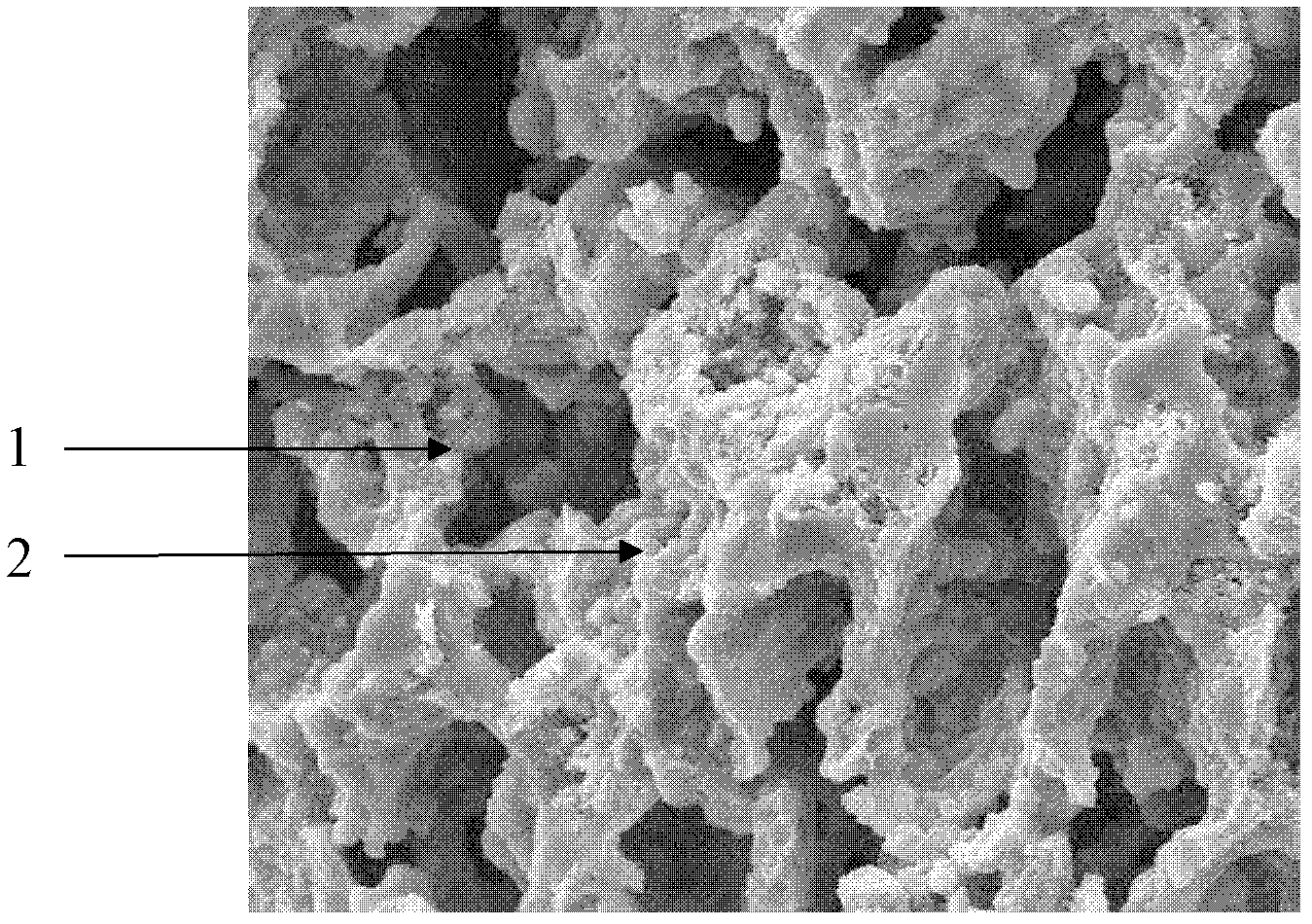

[0015] Embodiment 1: The method for preparing solid oxide fuel cell anode by impregnation method in this embodiment is carried out according to the following steps: 1. Mix the catalyst, dispersant and solvent evenly to obtain the impregnation solution, and the catalyst is a metal nitrate , metal ammonium salt, metal oxalate or metal organic acid salt, the metal in the catalyst is Ni, Cu, Ce, Co, Ag, Au, Pt, Pd, Rh or Ru, and the dispersant is alcohol (such as : ethanol), organic acid (such as: formic acid, acetic acid, oxalic acid, tartaric acid, malic acid, oxalic acid, benzoic acid, salicylic acid, caffeic acid), urea or ammonia water, solvent is water, alcohol or ether, catalyst The mass ratio of catalyst and dispersant is 100-1 / 100:1, and the total mass fraction of catalyst and dispersant is 0.1%-100%; 2. Introduce the impregnation solution into the porous anode support and bake it at 400°C; 3. Repeat Step 2. Operate 5 to 20 times, and sinter in a high-temperature furnace ...

specific Embodiment approach 2

[0021] Embodiment 2: This embodiment is different from Embodiment 1 in that: the porosity of the porous anode support in step 2 is 20%-70%, and the high temperature resistance is 500-1600°C. Other steps and parameters are the same as in the first embodiment.

[0022] In this embodiment, the porosity is preferably 40% to 70%, most preferably 50%.

[0023] The porous anode support body can be a porous high-temperature-resistant ceramic support body prepared as a raw material after fully mixing yttria-stabilized zirconia, alumina, ceria and its doped oxides with a pore-forming agent, or it can be Ni-Fe and other resistant A porous metal support prepared by a superalloy mixed with a pore-forming agent. The pore-forming agent of the porous anode support can use graphite, flour, starch, cellulose, citric acid, macromolecular organic matter, etc. Nitric acid is removed to create pores.

specific Embodiment approach 3

[0024] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: in step four, the reducing gas is H 2 or CH 4 . Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com