Precision building template system

A technology for building formwork and formwork, which is applied in construction, building structure, formwork/formwork components, etc., can solve the problem of difficulty in ensuring the strength of internal joints, and achieve the goal of improving strength, preventing slurry leakage, and ensuring flatness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

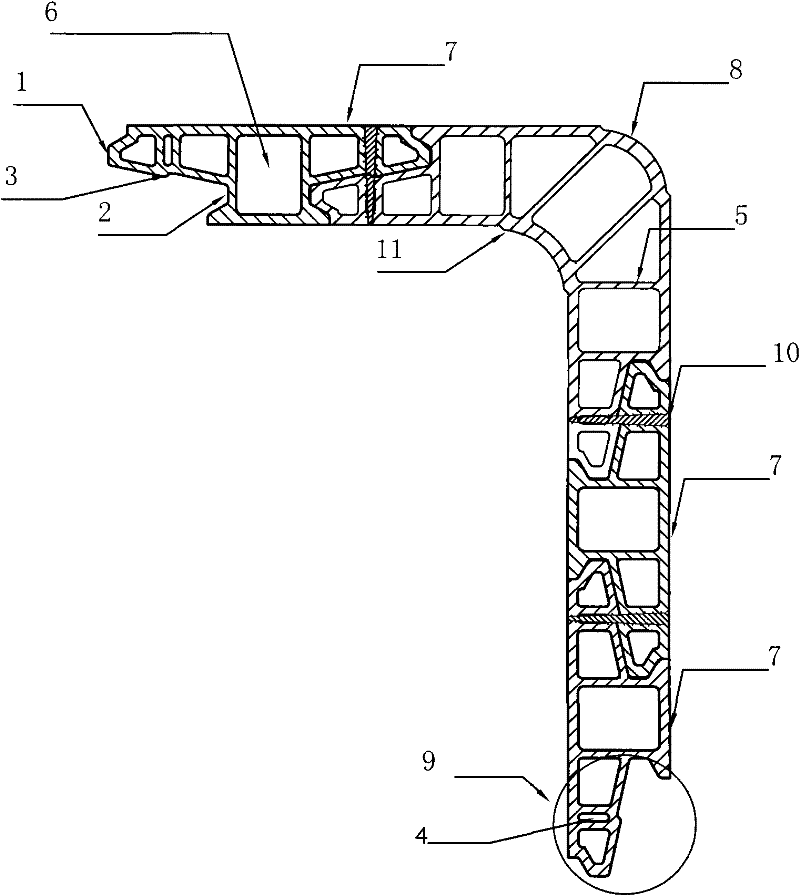

[0041] The building formwork that can be assembled according to the present invention is made up of several plane formwork 7 and corner piece formwork 8, and described plane formwork 7 and corner piece formwork 8 are all PVC materials, and the structure of described plane formwork 7 is as follows: figure 2 As shown, it can be seen from the figure that the planar formwork 7 has a symmetrical cross-section and has two panels, and a reinforcing rib is connected between the two panels, which is used to strengthen the planar formwork of the double-layer structure. 7 for structural connection and reinforcement; the planar template 7 has two splicing edges along the width direction that are respectively spliced with adjacent templates, and a connector 9 is formed on the splicing edges. It can also be seen from the figure that the planar template 7 also includes a reinforcement accommodating hole 6 , and the reinforcement accommodating hole 6 is centrally arranged in the middle of t...

Embodiment 2

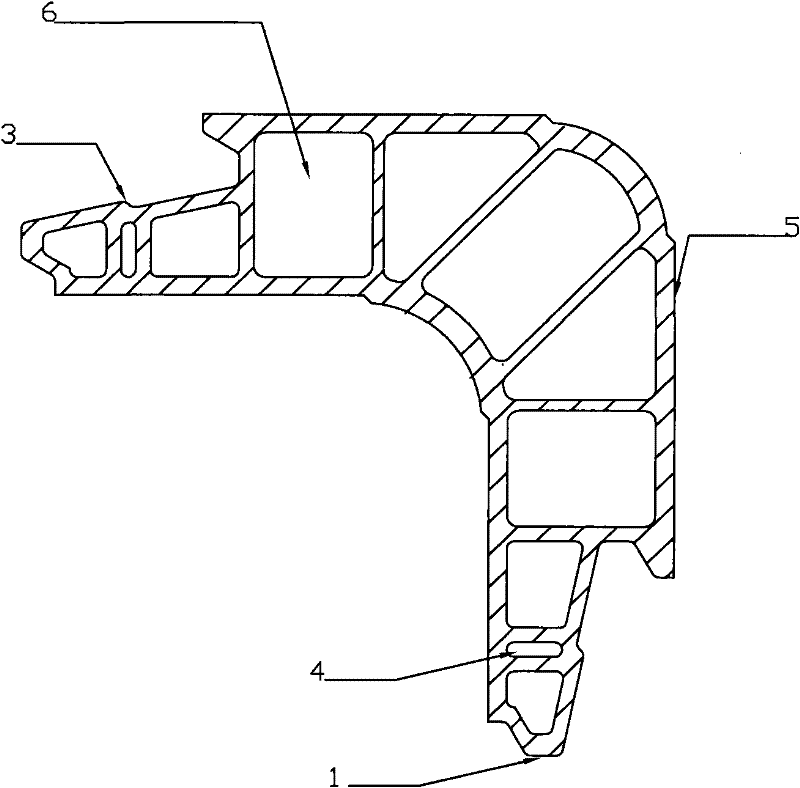

[0050] In this embodiment, the building formwork also includes the plane formwork 7 and corner fitting formwork 8. Compared with Embodiment 1, the corner fitting formwork 8 in this embodiment is at its corner Formed with rounded chamfers; in addition, in the above two templates in embodiment 1, no structure is provided on the transition surface between the chuck 1 and the slot 2. In this embodiment, the chuck 1 On the transition surface between the card slot 2 and the card slot 2, a card point 3 is formed. From the cross-section of the template, the shape of the card point 3 is that one side of the card head 1 protrudes from the card slot 3. Step shape on one side, the distance between the clamping point and the top surface of the clamping head is equal to the distance from the bottom surface of the clamping slot. In this way, after two adjacent planar formworks 7 or adjacent planar formworks 7 and corner fitting formworks 8 are plugged in, the clamping point 3 can be aligned ...

Embodiment 3

[0059] Under the condition that other conditions remain unchanged in the aforementioned Example 1 and Example 2 of the present invention, as a changeable embodiment, the shapes of the clip head 1 and the clip slot 2 of the building formwork of the present invention can also be selected It can be set to any shape that can be matched to realize insertion, as long as a card point can be formed between the card slot 2 and the card head 1 to realize self-fastening after insertion.

[0060] In this embodiment, a boss 11 protruding toward the side of the pouring material is also formed at the corner of the corner fitting formwork. When in use, it is not necessary to insert the self-tapping screws at all formwork joints after pouring. To disassemble, only need to dismantle the self-tapping screw at one of the sockets, that is, the boss 11 can be used as a supporting point to dismantle the template as a whole, which is very convenient to use.

[0061] Apparently, the above-mentioned em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com