Upper vibration plate type steel wire continuous ultrasonic cleaning machine set

An ultrasonic and vibrating plate technology is applied in the field of continuous ultrasonic cleaning unit of upper vibrating plate type steel wire to achieve the effect of good cleaning quality, high cleaning efficiency and small space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

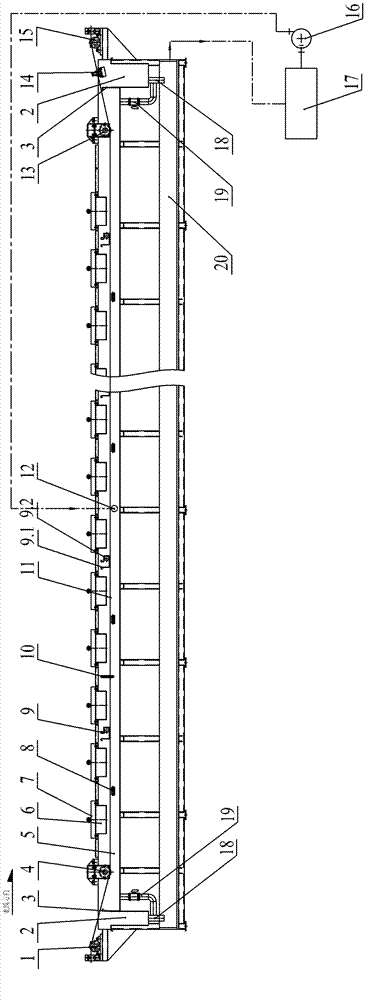

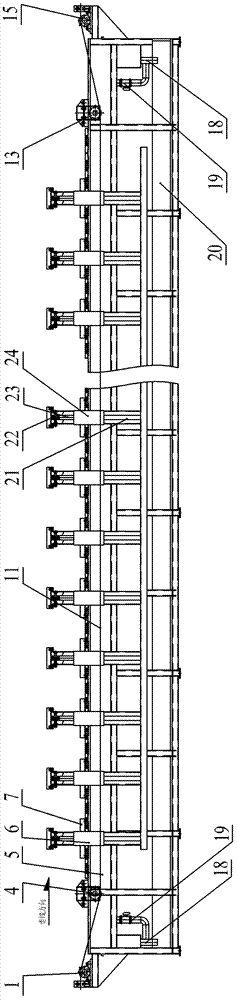

[0021] The present invention will be further described below in conjunction with specific drawings and embodiments.

[0022] As shown in the figure: the upper vibrating plate type steel wire continuous ultrasonic cleaning unit is mainly composed of an incoming wire separation roller 1, an overflow baffle 3, an incoming wire pressing roller 4, a cleaning tank 5, an ultrasonic vibrating plate 6, and a cover plate 7 , grinding stone 8, anti-jumping roller device 9, liquid level detector 10, liquid inlet pipe 12, wire pressing roller 13, wiping device 14, wire separating roller 15, circulation pump 16, lower sedimentation tank 17 , overflow pipe 18, blowdown pipe 19, support 21, pulley 22, steel rope 23 and counterweight block 24 parts and components.

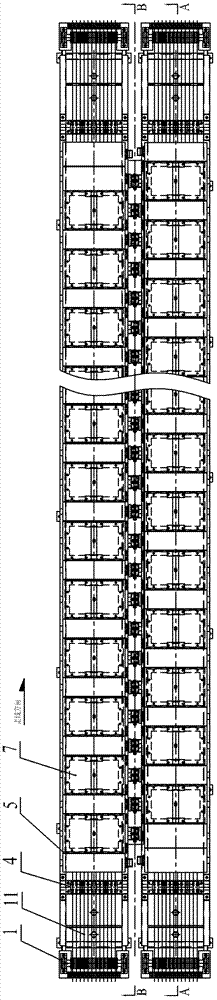

[0023] Such as Figure 1~Figure 3 As shown, there are two cleaning tanks 5, both of which are elongated, and the two cleaning tanks 5 are arranged side by side, and one end of the incoming line of the two cleaning tanks 5 is equip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com