Millet sake and preparation method thereof

A technology for millet and sake, applied in the preparation of alcoholic beverages, biochemical equipment and methods, and methods based on microorganisms, can solve the problems of monotonous flavor and weak taste, and achieve harmonious flavors, unique style, and mellow and soft taste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

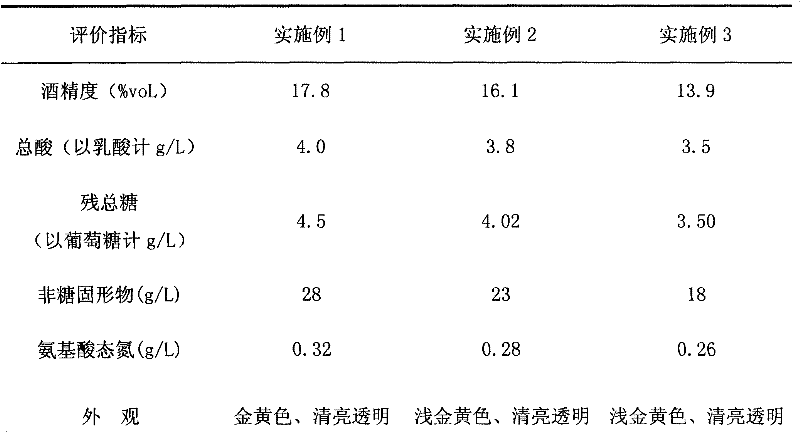

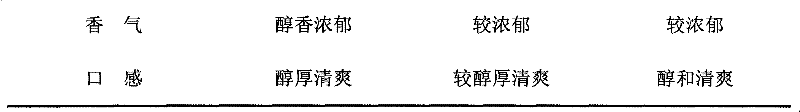

Embodiment 1

[0050] The preparation of embodiment 1 millet sake

[0051] 1. Crush the millet with a claw-type grinder and pass through a 40-mesh sieve.

[0052] 2. First heat the water to 65°C through a thin plate heat exchanger, and put it into the slurry tank. The amount of water is 650L. Under stirring, slowly add 500Kg of millet flour, with 10% (w / w) concentration of Na 2 CO 3 The solution adjusts the pH value of the slurry to 6.3, then adds medium-temperature α-amylase (12u / g raw material), and stirs evenly.

[0053] 3. Add 100L of bottom water into the liquefaction tank, turn on the steam to heat, and when the temperature of the bottom water reaches 80°C, pump the powder slurry into the cross-shaped feeding pipe, and spray it out from the small hole of the feeding pipe. At this time, adjust the flow rate of the heating steam and the slurry to maintain the temperature of the slurry in the tank at 80°C. After the powder slurry is beaten, the temperature in the tank continues to be ...

Embodiment 2

[0059] The preparation of embodiment 2 millet sake

[0060] 1. Crush the millet with a claw-type grinder and pass through a 30-mesh sieve.

[0061] 2. First heat the water to 65°C through a thin-plate heat exchanger, and pour it into the slurry tank. The amount of water is 800L. Under stirring, slowly add 500Kg of millet flour, with 10% (w / w) concentration of Na 2 CO 3 The solution adjusts the pH value of the slurry to 6.2, then adds medium-temperature α-amylase (11u / g raw material), and stirs evenly.

[0062] 3. Add 100L of bottom water into the liquefaction tank, turn on the steam to heat, and when the temperature of the bottom water reaches 85°C, pump the powder slurry into the cross-shaped feeding pipe, and spray it out from the small hole of the feeding pipe. At this time, adjust the flow rate of the heating steam and the slurry to maintain the temperature of the slurry in the tank at 85°C. After the powder slurry is beaten, the temperature in the tank continues to be...

Embodiment 3

[0068] The preparation of embodiment 3 millet sake

[0069] 1. Crush the millet with a claw-type grinder and pass through a 30-mesh sieve.

[0070] 2. First heat the water to 65°C through a thin plate heat exchanger, and pour it into the slurry tank. The amount of water is 1000L. Under stirring, slowly add 500Kg of millet flour, with 10% (w / w) concentration of Na 2 CO 3 The solution adjusts the pH value of the slurry to 6.4, then adds medium-temperature α-amylase (10u / g raw material), and stirs evenly.

[0071] 3. Add 100L of bottom water into the liquefaction tank, turn on the steam to heat, and when the temperature of the bottom water reaches 90°C, pump in the slurry, and the slurry enters the cross-shaped feeding pipe, and is sprayed out from the small hole of the feeding pipe. At this time, adjust the flow rate of the heating steam and the slurry to maintain the temperature of the slurry in the tank at 90°C. After the powder slurry is beaten, the temperature in the tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com