Method for treating and printing and dyeing wastewater by using hydrolysis tank

A technology of printing and dyeing wastewater and hydrolysis pool, which is applied in textile industry wastewater treatment, multi-stage water/sewage treatment, biological water/sewage treatment, etc. It can solve the problems of no successful cases, reduced effective pool capacity, and reduced treatment efficiency. Achieve the effects of easy film formation, promotion of metabolism and renewal, and improvement of treatment efficacy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

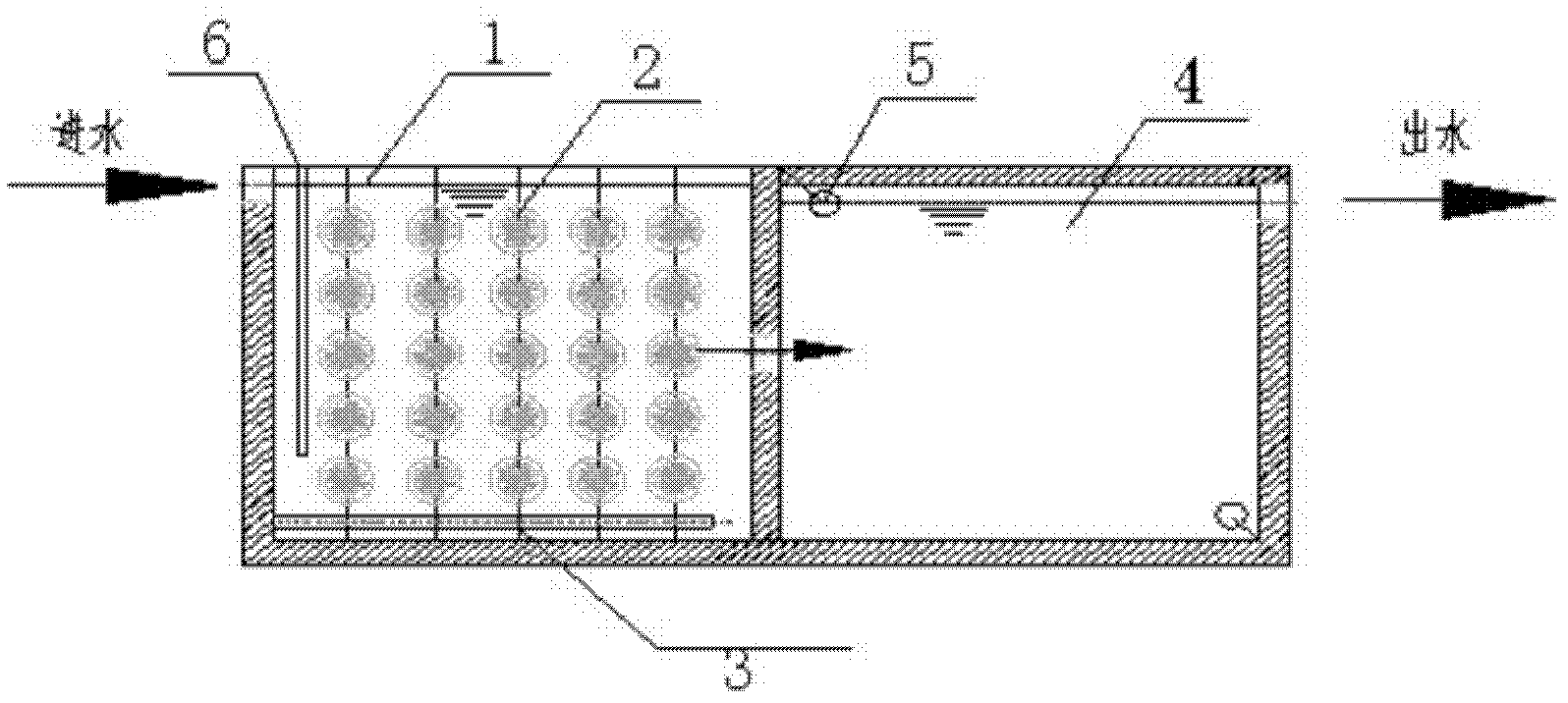

[0025] The printing and dyeing wastewater is biodegradable wastewater containing PVA slurry; the hydrolysis pool is divided into two parts, the first half pool 1 and the second half pool 4, the first half pool of the hydrolysis pool has a water inlet, and the second half pool of the hydrolysis pool has a water inlet. Water outlet, the second half pool 4 is connected in series with the oxidation ditch 10 and the secondary sedimentation tank 11; the first half pool 1 is an open pool with an upper opening, and the first half pool 1 is added with filler 2, and the first half pool 1 A perforated intermittent aerator 3 is arranged at the bottom, and a baffle plate 6 is arranged at the water inlet of the first half pool 1, and the baffle plate is suspended above the first half pool of the hydrolysis tank, and the height of the baffle plate is less than the depth of the hydrolysis tank; The half pool 4 is a closed pool closed above, and there are submersible mixers 5 at both ends of a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com