Positioning and locking device of large guide rail type hoisting crane

A positioning and locking, guide rail-type technology, applied in the direction of safety devices, transportation and packaging, load hanging components, etc., can solve problems such as time-consuming and laborious, and achieve the effect of reducing operating time, saving labor costs, and facilitating positioning and locking operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

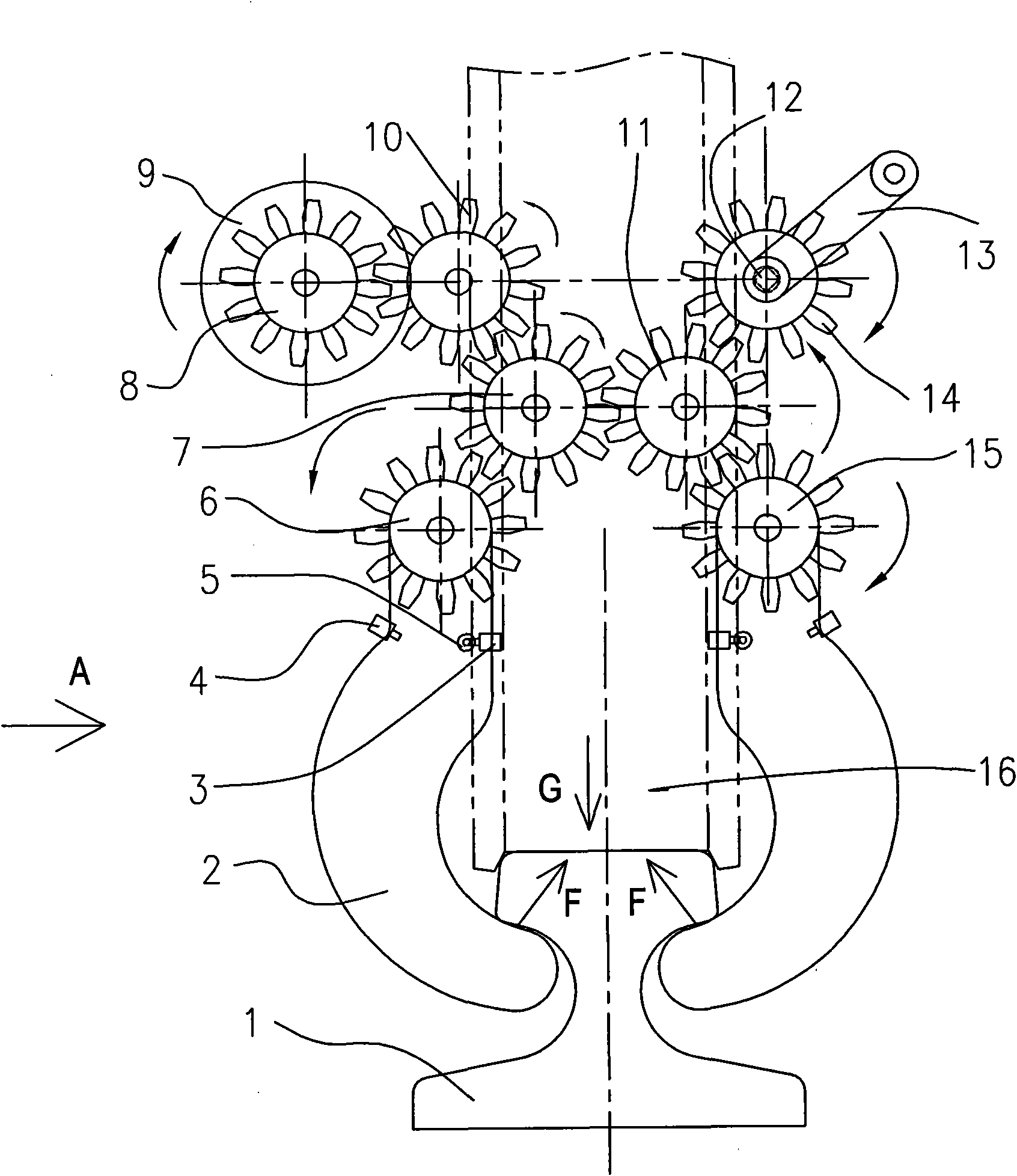

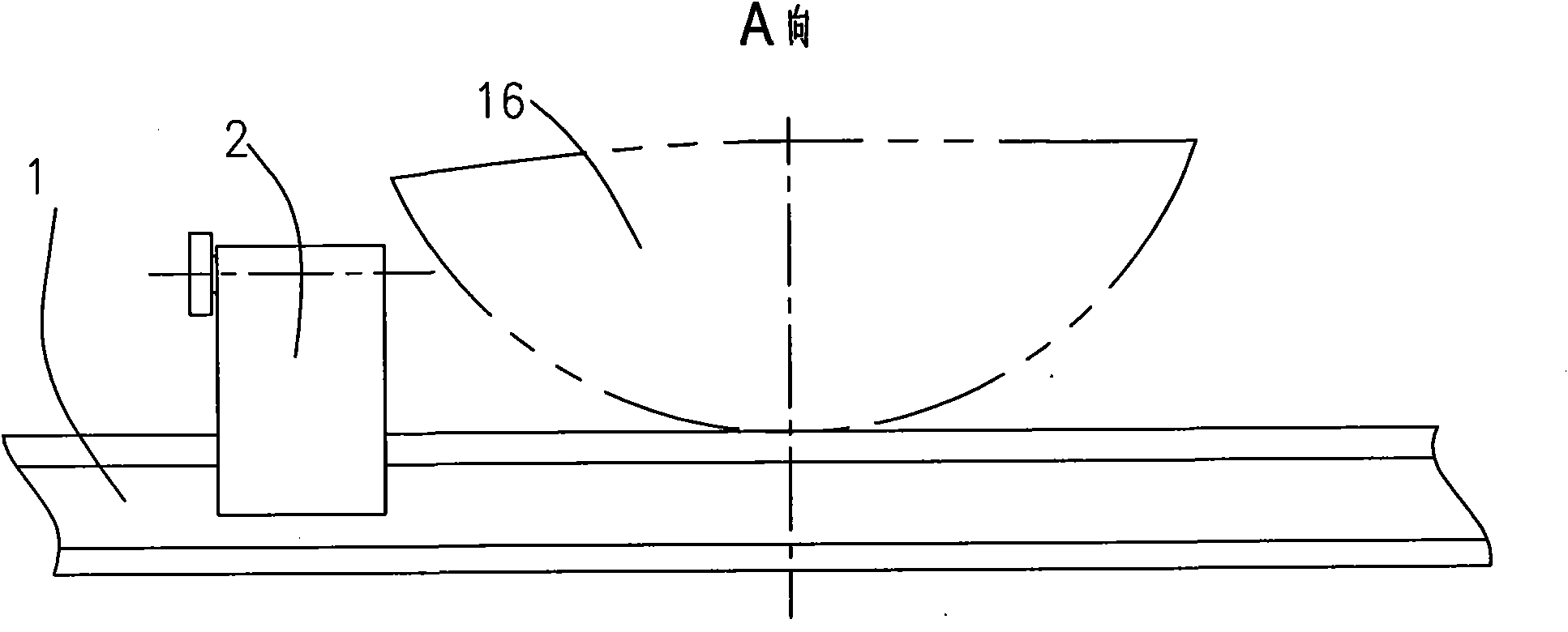

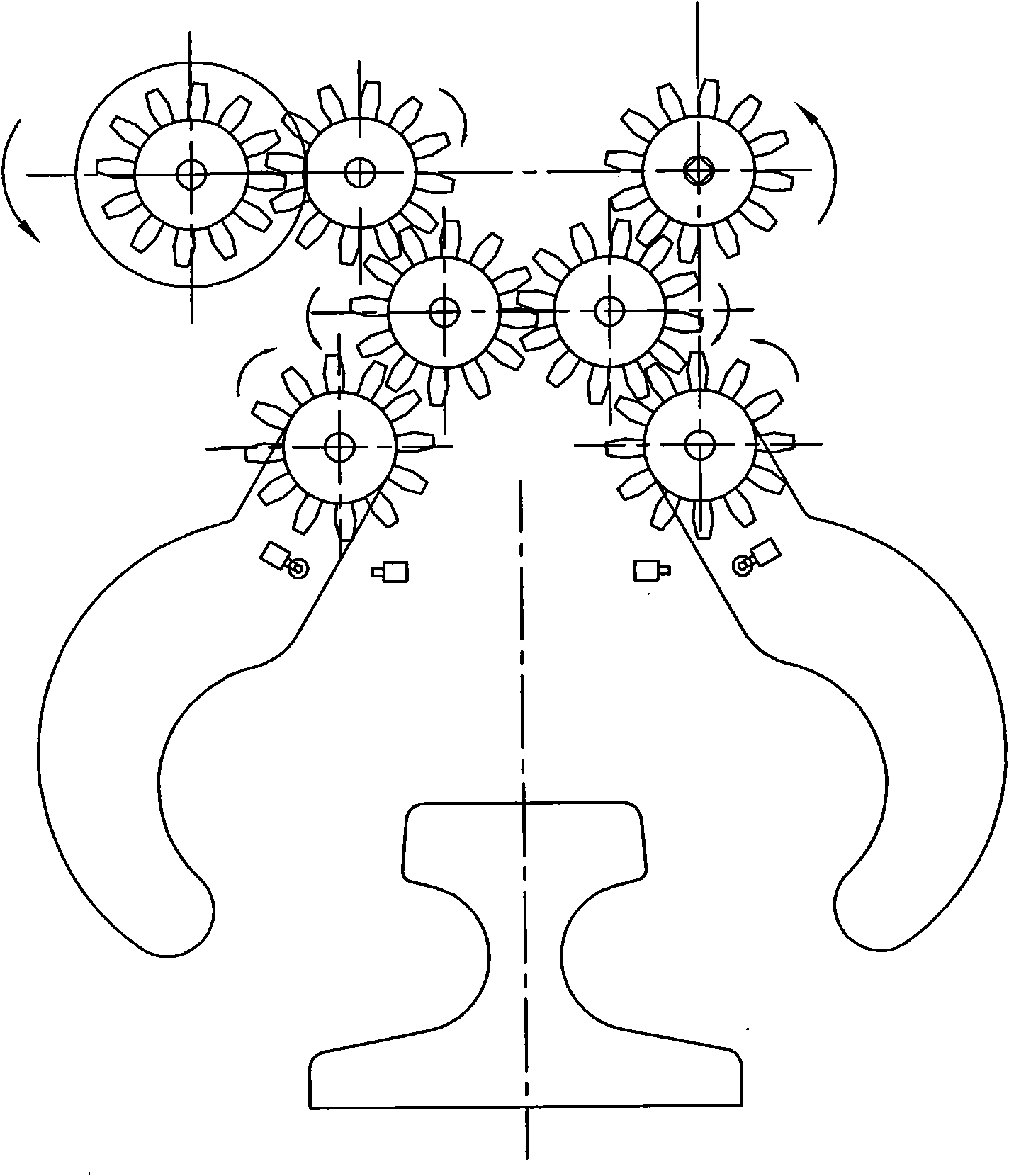

[0015] The present invention as figure 1 , 2 Shown: it is arranged on the bottom of the vehicle body behind the driving wheel 16 of the hoisting crane, and it includes a controller, a stop clamp 1, a stop clamp 2, an open position limit switch, a closed position limit switch and a transmission mechanism;

[0016] Described transmission mechanism comprises drive motor 9, main transmission gear 10, intermediate transmission gear 7, reversing transmission gear 11, stop pliers one drive gear 6 and stop pliers two drive gears 15; Described drive motor 9 has output shaft, The output shaft is provided with an output gear 8, the output gear 8 meshes with the main transmission gear 10, the main transmission gear 10 meshes with the intermediate transmission gear 7, and the intermediate transmission gear 7 is respectively engaged with the The reversing transmission gear 11 is engaged with the first drive gear 6 of the stop pliers, and the reversing transmission gear 11 is engaged with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com