Railway tank car

A technology for railway tanks and tank cars, which is applied to tank cars, railway car body parts, transport passenger cars, etc., can solve problems such as potential safety hazards and affect the unloading rate, and achieve the effects of safe operation, reliable operation and high unloading rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

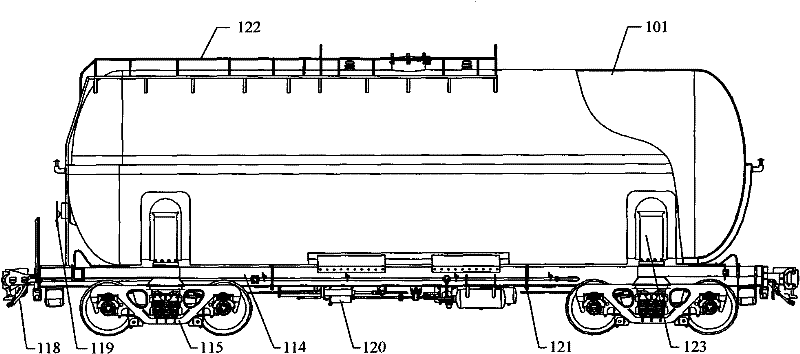

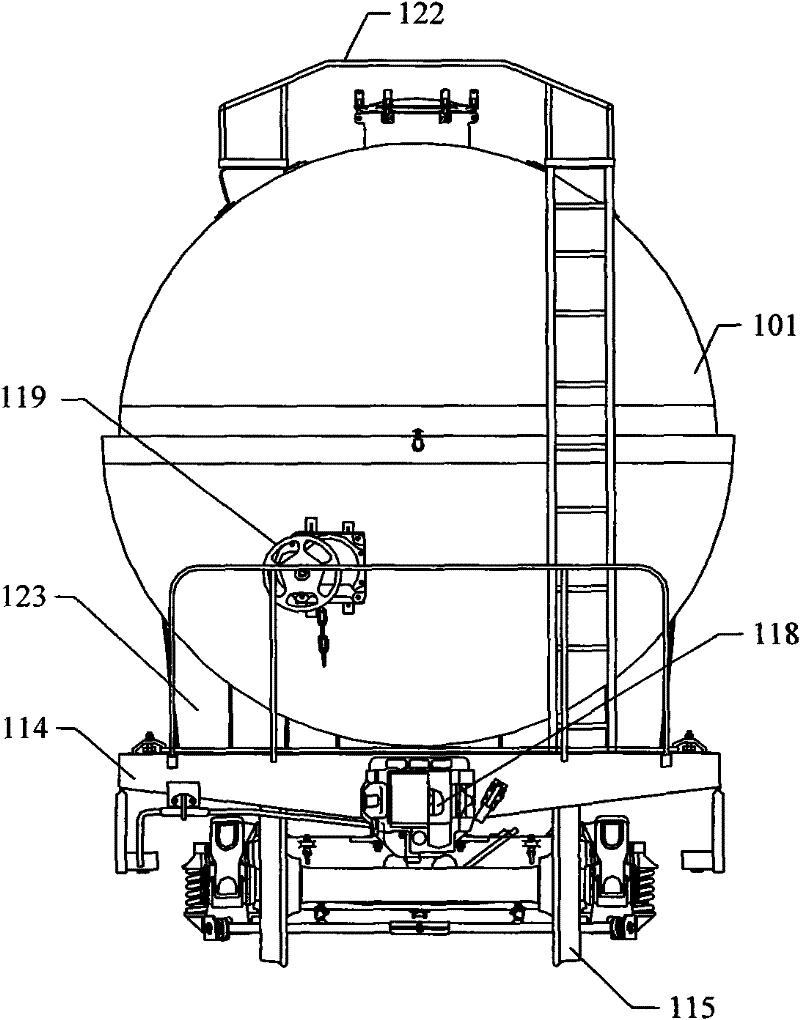

[0017] The material loaded by the railway tank car of the present invention is a material that is solid under low-temperature transportation conditions (this type of material can be p-xylene). For the characteristics of this type of material, although in the process of unloading, the tank body can be heated by heating equipment It is heated to make it liquid; but because the existing railway tank car has a structure of loading and unloading, it seriously affects the unloading rate of the railway tank car, so it is necessary to improve the relevant structure of the tank body to increase the unloading rate.

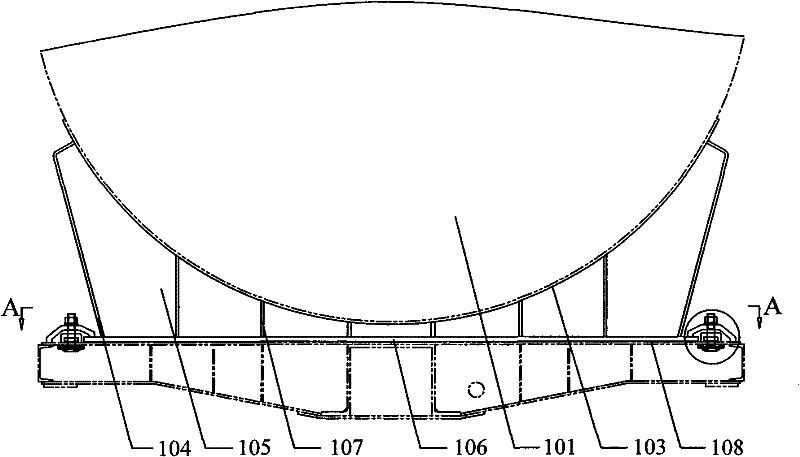

[0018] Furthermore, the railway tank car of the present invention is aimed at the related structure that the tank body and the chassis of the current railway tank car are mostly connected by tank belts, which affects the imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com